A fracture seepage tester under the action of high water head and high stress

A high-stress, high-head technology, applied in the field of hydraulic engineering, can solve the problems that the engineering reality is far apart, and the conditions and processes of crack filling under different graded soils cannot be reflected from the mesoscopic point of view.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

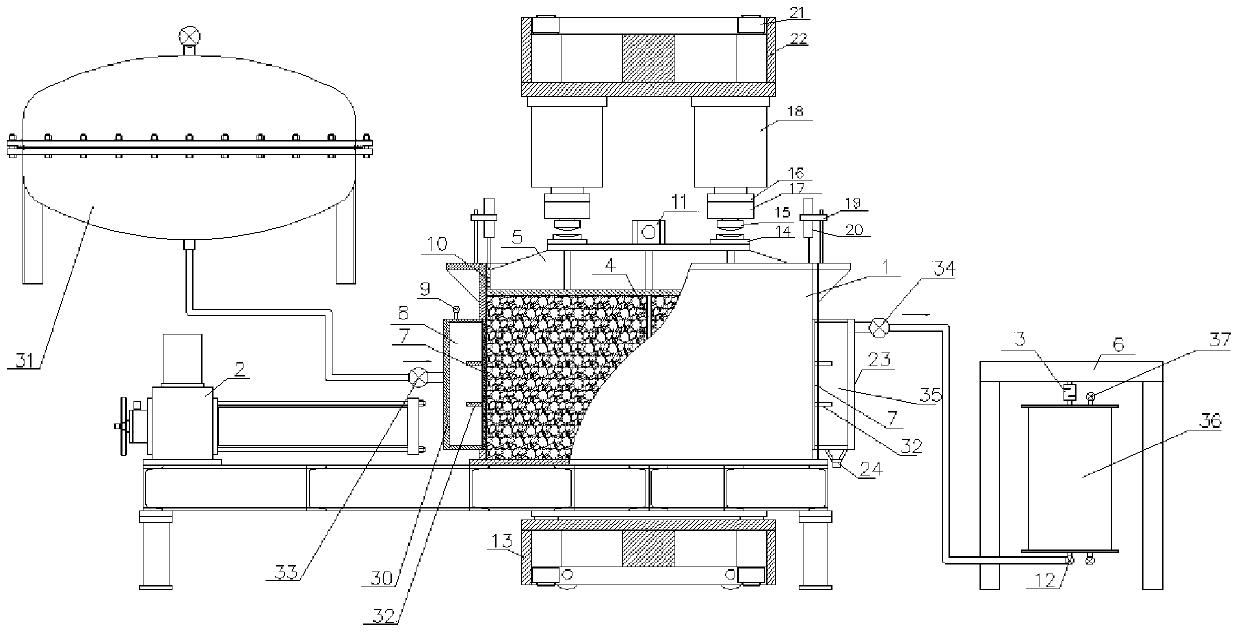

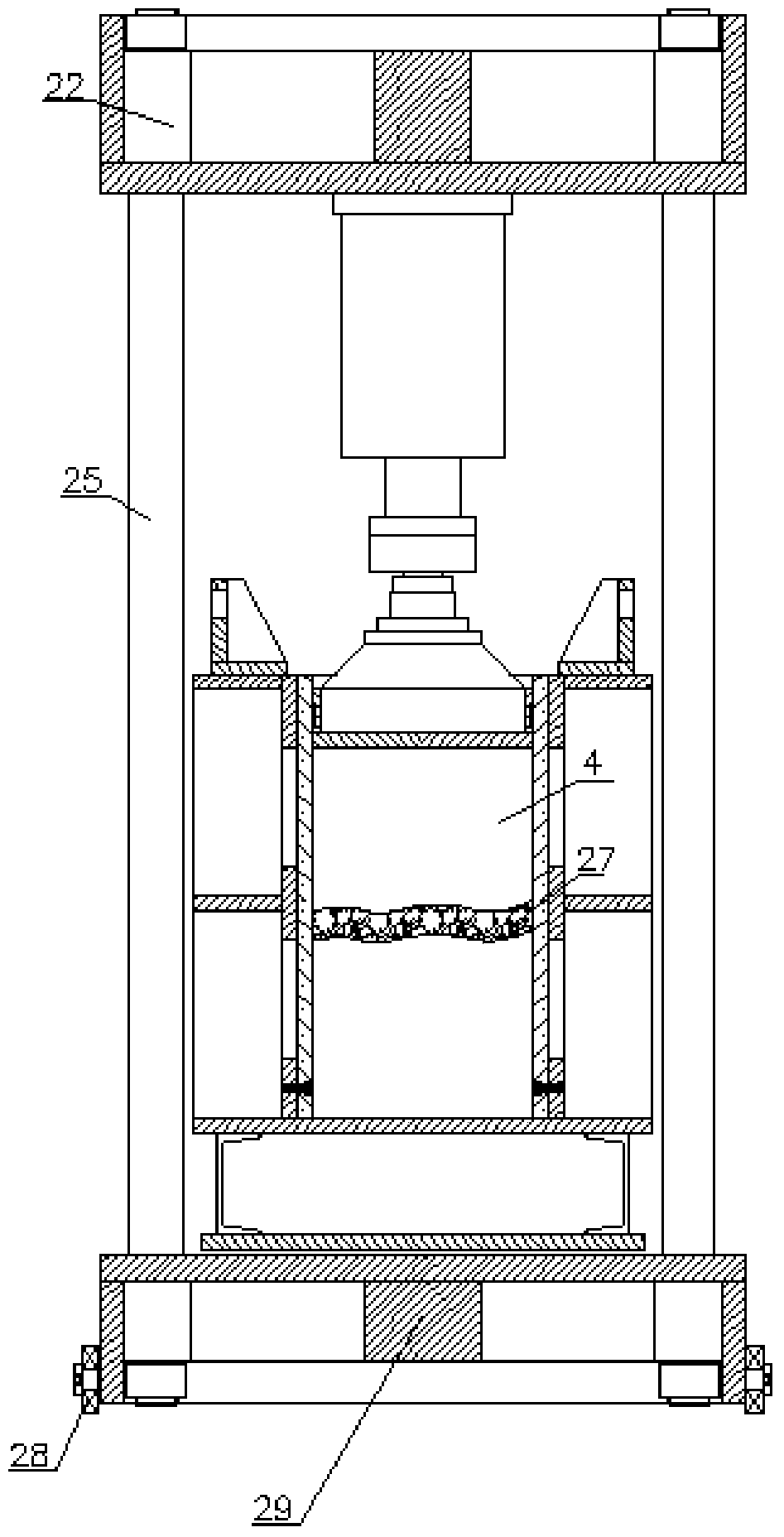

[0037] In order to solve the seepage characteristics of the cut-off wall after cracking under the coupling action of high water head and high stress in the deep overburden layer, a crack seepage tester under the action of high water head and high stress is invented and provided, which can be used to study concrete The evolution mechanism of local seepage after cracks in cut-off walls reveals the influence of high stress, high hydraulic gradient, crack opening, roughness, number of cracks, and filling conditions on crack seepage.

[0038] refer tofigure 1 , shows a schematic structural view of the fracture seepage tester under the action of high water head-high stress in an embodiment of the present invention, including a test tank 1, a front water collection box 30, a rear water collection box 23 and a longitudinal pressurization devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com