Reactor-circuit main pump motor electric engine driving apparatus

A technology of electric cranking and pump motors, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc. It can solve problems such as unsafe climbing up and down, heavy workload, and concentricity deviation between the tool shaft and the motor shaft. , to achieve the effects of reducing industrial safety hazards, safe and reliable use, and sensitive rotation and stop points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

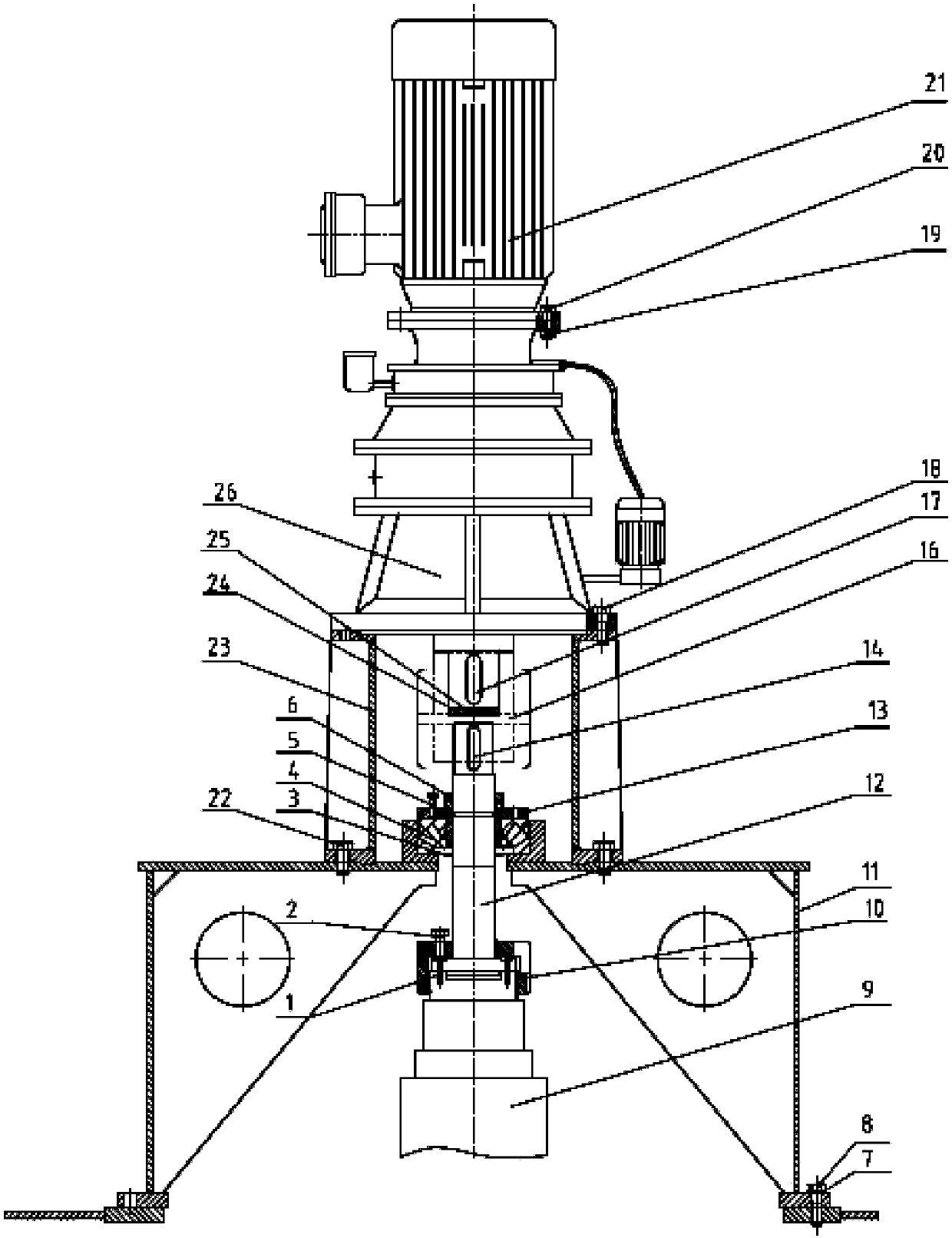

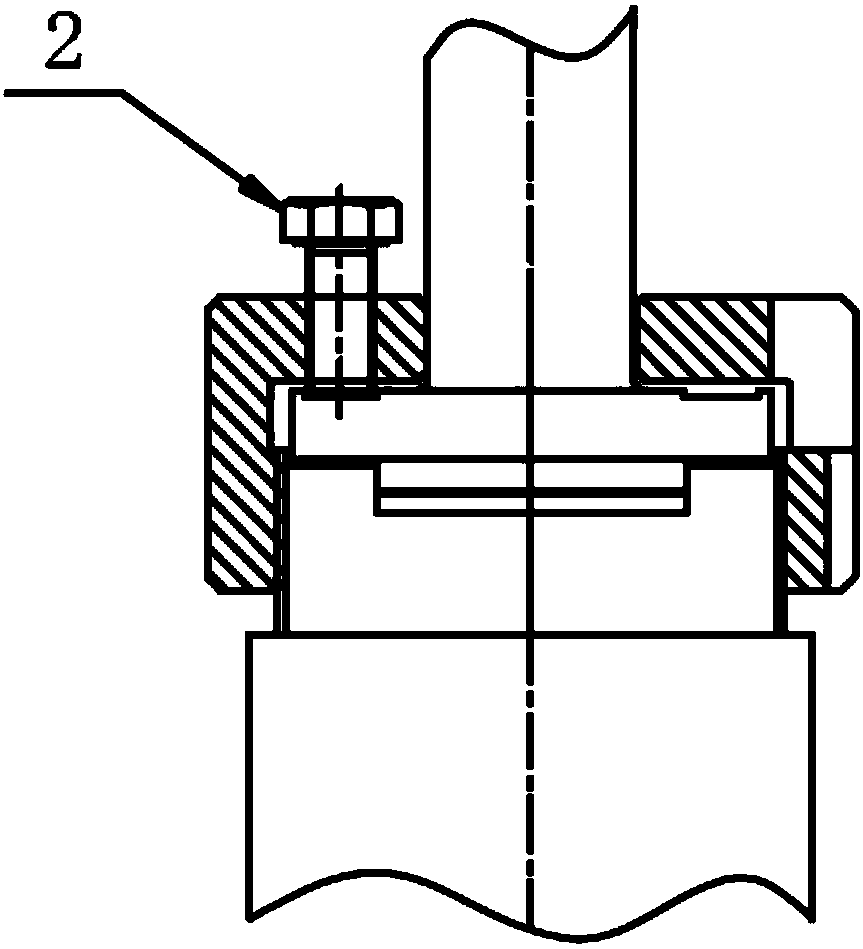

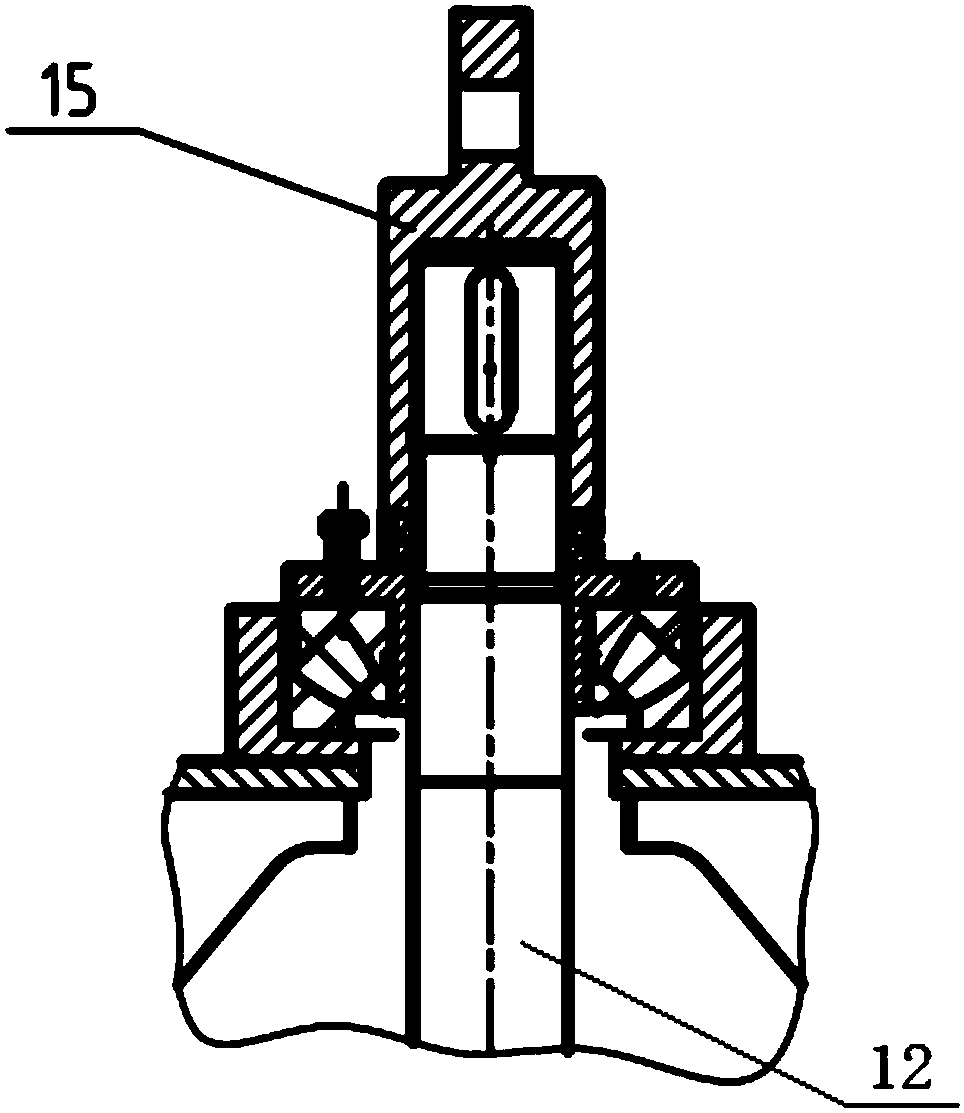

[0032] Such as figure 1As shown, an electric cranking device for the main pump motor of the primary circuit of a reactor includes a jacking bolt 2, an oil deflector ring 3, a bearing 4, a thrust nut 6, a connecting nut 10, a bracket 11, a tool shaft 12, a bearing sleeve 13, and a motor 21, reducer bracket 23, baffle plate 24 and reducer 26. The motor 21 is installed on the upper end of the reducer 26, and the output end of the motor 21 is connected with the input end of the reducer 26; the motor 21 is used to provide turning power. The lower end of the reducer 26 is fixed on the upper end of the reducer bracket 23 , and the reducer shaft extends downward and is located inside the reducer bracket 23 ; the reducer 26 is used to decelerate the motor 21 . The baffle plate 24 is fixed on the lower end surface of the reducer shaft for buffering. The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com