Numerical control current conversion system adopting parallel decoding mode

A technology of current conversion and mode, which is applied in the direction of analog-to-digital converter, analog-to-digital conversion, code conversion, etc., can solve the problems of slow driving ability and operation speed, inconvenient general use, and low precision, so as to achieve fast load dynamic response and avoid The effect of concentrated heat generation and high response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

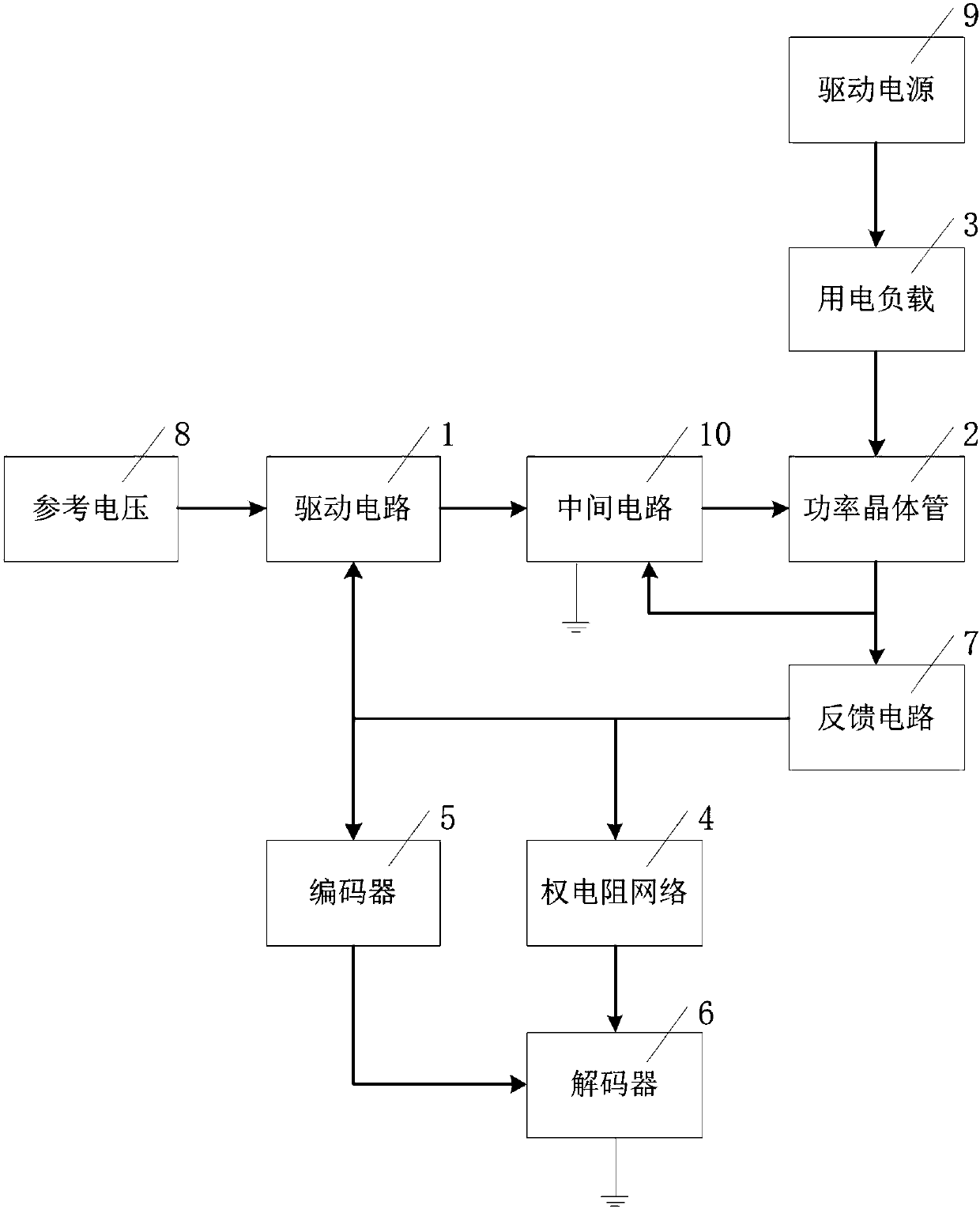

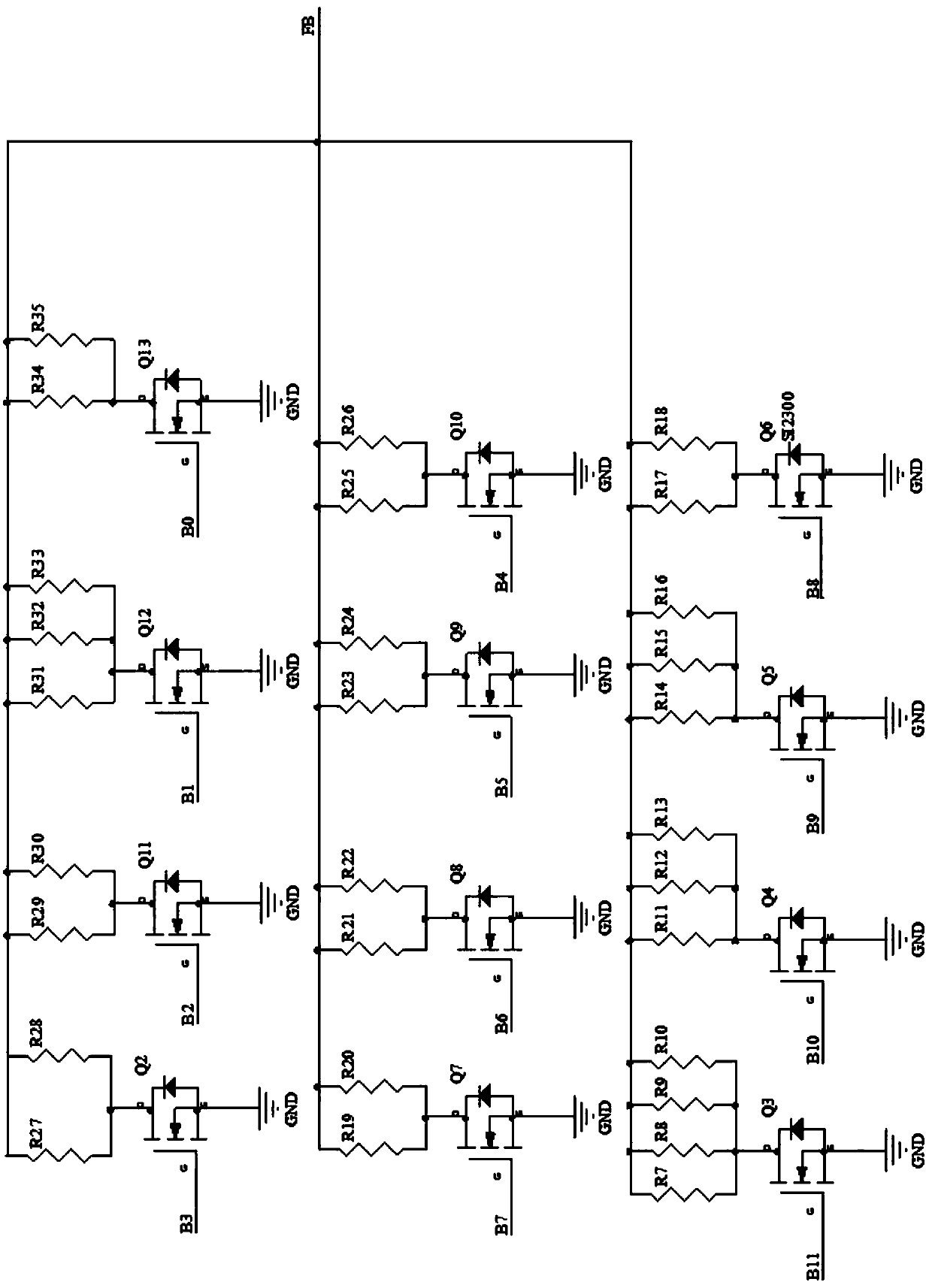

[0026] refer to Figure 1 ~ Figure 3 As shown, this embodiment discloses a digitally controlled current conversion system using a parallel decoding mode, including:

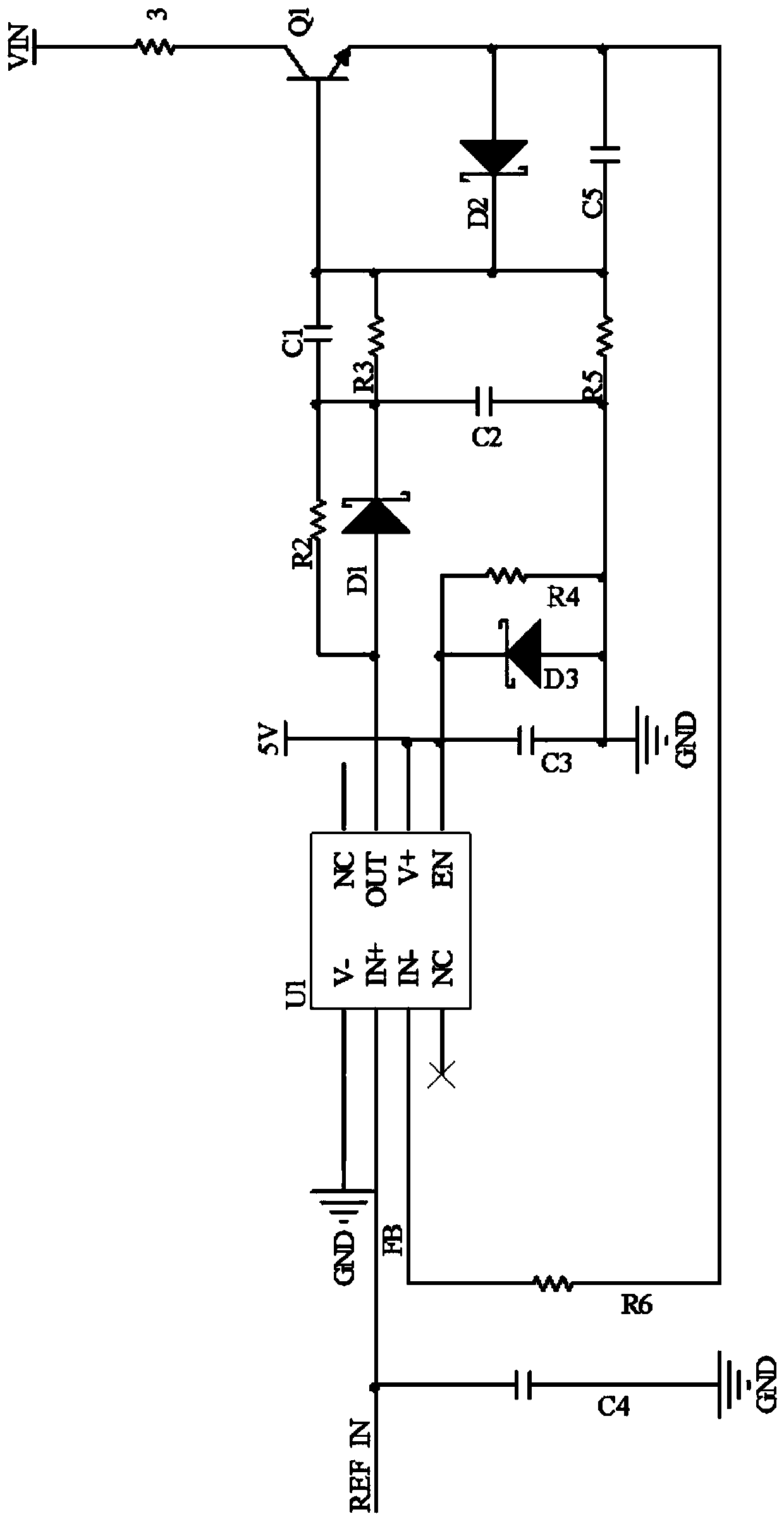

[0027] Drive circuit 1: The drive circuit 1 includes an operational amplifier U1, the input terminal IN+ of the operational amplifier U1 is connected to the reference voltage 8, the reference voltage 8 inputs the reference signal REF IN, and a fourth capacitor is connected between the contact of the reference voltage 8 and the input terminal IN+ and the ground C4. The operational amplifier U1 is externally connected with a power supply for its operation, the enabling terminal EN of the operational amplifier U1 is connected to the power supply, and a third capacitor C3 is connected between the enabling terminal EN and the ground. The third capacitor C3 and the fourth capacitor C4 are used to filter out AC components in the power supply and REF IN respectively, and the operational amplifier U1 has an operational a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com