Dual-layered and flexible-profiling corn picking and peeling apparatus with variable gap

A variable-gap, double-layer technology, applied in harvesters, agriculture, applications, etc., can solve problems such as increasing the contact and collision between corn ears and mechanical parts, improving the collision loss of corn ears, corn ear gnawing, etc., to save harvesting Effects of mechanical space, reduction of picking loss and damage, and reduction of collision damage and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

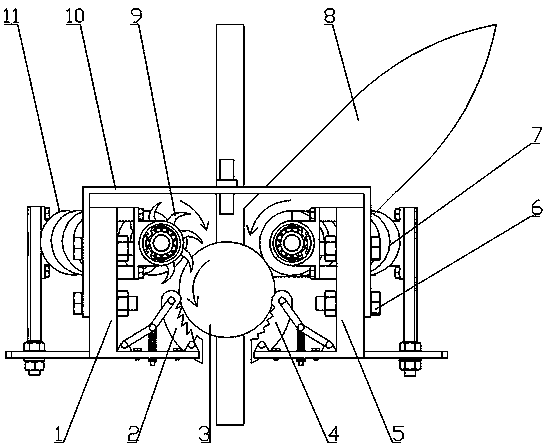

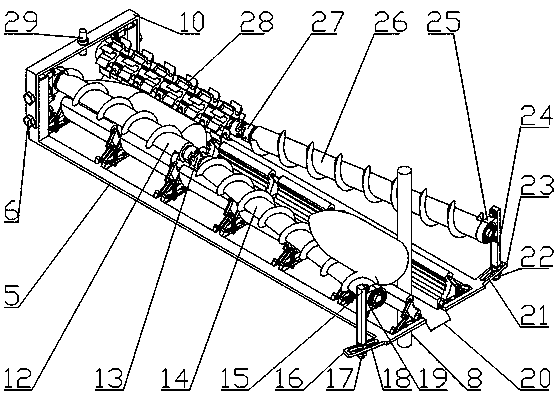

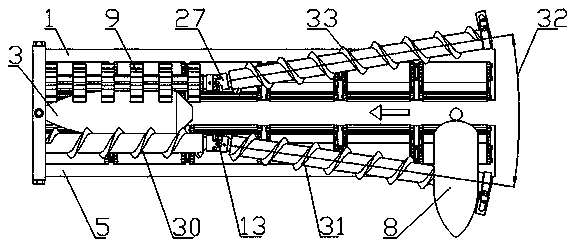

[0019] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5Shown, the present invention includes left frame 1, left profiling mechanism 2, right profiling mechanism 4, right frame 5, right plucking ear peeling mechanism 7 and left plucking fringe peeling mechanism 11, and left profiling mechanism 2 is fixed on Below the left frame 1, the left ear picking and peeling mechanism 11 is fixed on the top of the left frame 1, the right profiling mechanism 4 is fixed on the bottom of the right frame 5, and the right ear picking and peeling mechanism 7 is fixed on the top of the right frame 5 , the U-shaped beam 10 is fixed on the upper rear end of the left frame 1 and the right frame 5 by the first bolt 6, and the infrared sensor 29 is fixed on the middle part of the U-shaped beam 10; Front end left side, the middle part of left arc plate 23 offers left arc groove 21; Right arc plate 16 is fixed on the front right side of right frame 5, and the middle part of right arc pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com