Drying machine

A dryer and main body technology, applied in the direction of dryer, drying, drying solid materials, etc., can solve the problems of high production cost, complex structure, large equipment investment, etc., achieve good dehydration effect, simple structure and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

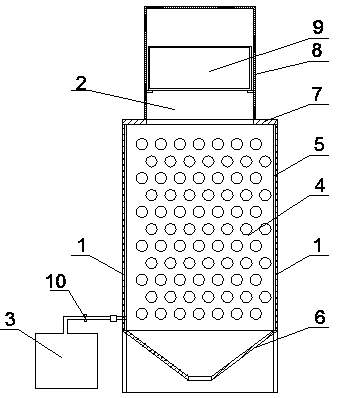

[0017] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

[0018] like figure 1 As shown, a dryer includes a main body 1, a filter unit 2, a hot air supply unit 3 and a heating pipe 4, the filter unit 2 includes a fixing frame 8 and a screening basket 9; the main body 1 includes a front baffle plate, rear baffle, left side plate and right side plate, and form a cylindrical space, the inner side of each plate is provided with a heating layer 5, the upper part of the rear baffle is provided with a first row of holes, in the first row The bottom of the hole is opened with a second row of holes offset to the right, and the first row of holes and the second row of hole arrays are arranged on the rear baffle with evenly distributed holes A, and the front baffle is provided with the rear baffle. The relat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap