Multifunctional pulp homogenizing machine

A homogenizer and multi-functional technology, which is applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems of reduced service life of motors, damage of stirring devices, low safety factor, etc., to reduce service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

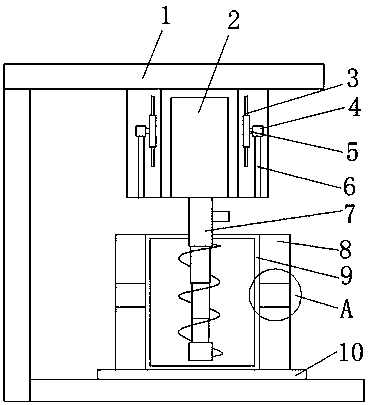

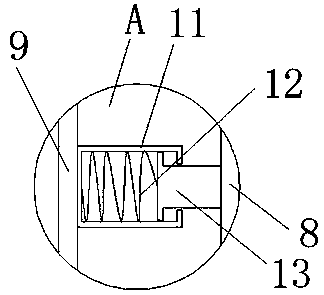

[0018] refer to Figure 1-2 , a multifunctional homogenizer, comprising a support frame 1, a housing 8 is installed on the bottom side wall of the upper bracket of the support frame 1, the housing 8 is a cavity structure, and the inside of the housing 8 is equipped with a vertically placed Support rods 6, two support rods 6 are arranged inside the housing 8, and they are placed parallel to each other vertically. The upper end of the support rods 6 is equipped with a micro motor 4, and one side of the housing 8 is provided with a valve near the position of the micro motor 4. , and the valve is connected with a vertically placed rotating rod inside the housing 8, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com