Automatic straightening machine for shaft tube part

A technology for straightening machines and parts, applied in the field of straightening machines, can solve the problems of insufficient straightening accuracy and efficiency, inaccurate maximum deflection surfaces, and unavoidable problems of maximum deflection surface offset, achieving a high degree of automation and improving efficiency. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

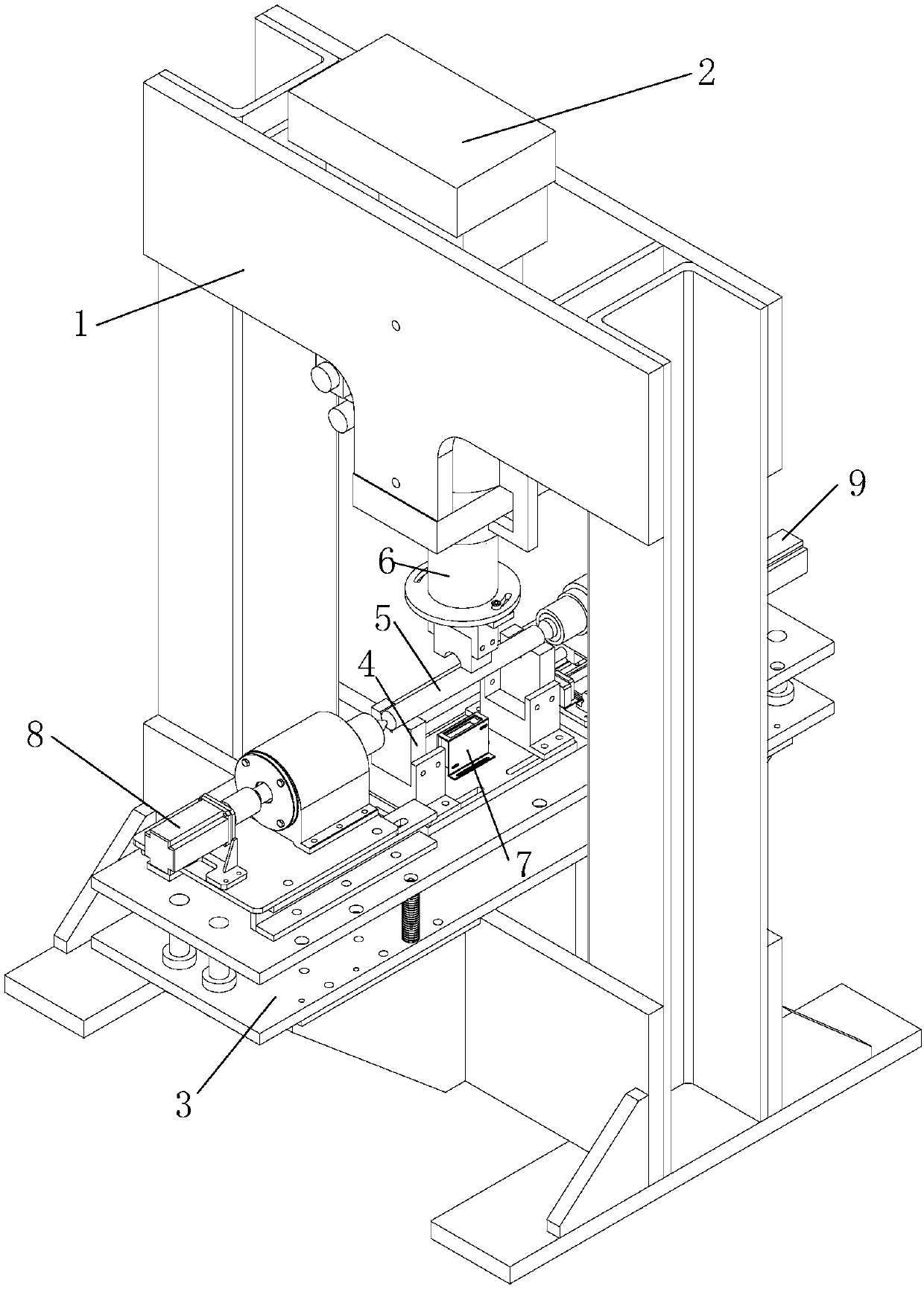

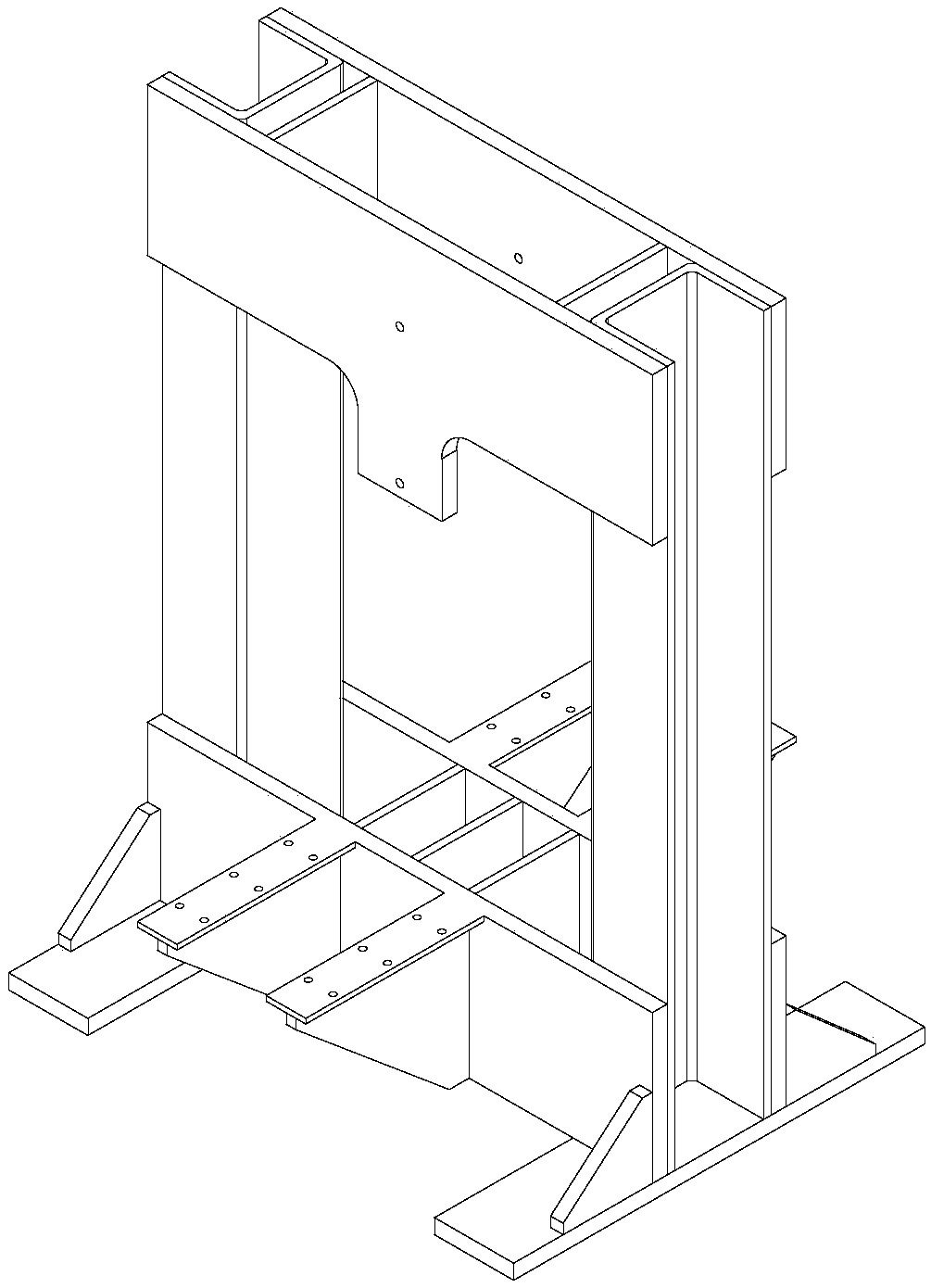

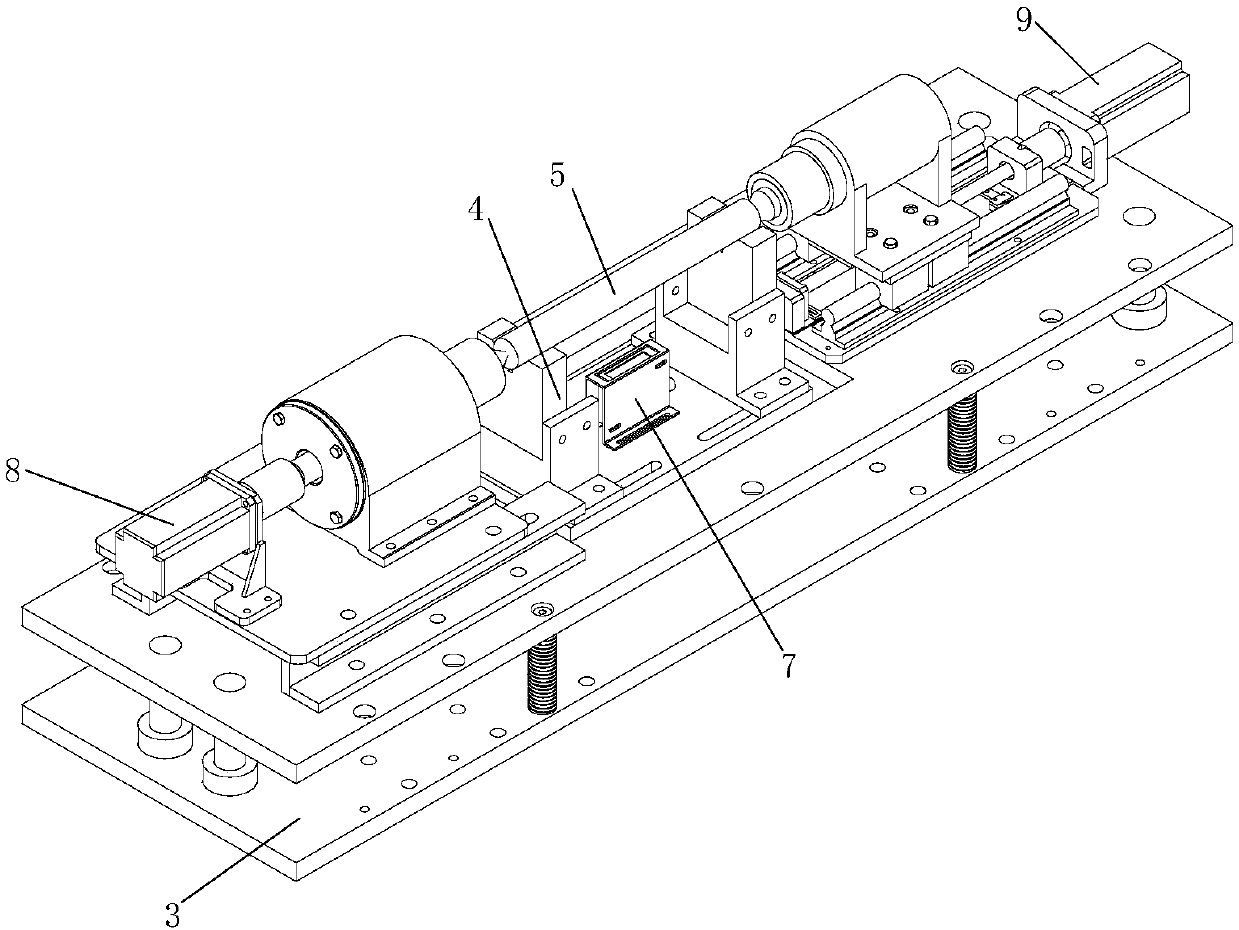

[0023] exist figure 1 , figure 2 and image 3 In the schematic diagram of the automatic straightening machine for shaft and tube parts shown, the frame 1 is a frame structure, the columns on both sides are channel steel, the upper beam is two T-shaped steel plates parallel to each other, and the electric cylinder 2 is connected to the protruding part of the steel plate by bolts Fixed connection, the pressure head 6 is connected with the output shaft of the electric cylinder, the lower beam is two parallel steel plates, each steel plate is equipped with two symmetrical ribs, and the floating workbench 3 is fixed to the ribs of the lower beam by bolts Above; the left rotating device 8 and the right clamping device 9 are respectively set on the left and right sides of the floating workbench, the support seat 4 is set at the central position of the lower fixed plate of the floating workbench, and the alignment member 5 is placed on the support seat , the detection and sensing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com