Double-boosting type large-curvature coreless bending forming die of thin-walled pipe and forming method thereof

A bending forming and bending die technology, applied in the field of pipe bending and forming, can solve the problems of difficult bending and low yield of pipe fittings, and achieve the ideal effect of improving bending limit, pipe wall thickness uniformity and section distortion degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The first embodiment is a double-assist type thin-walled pipe fitting with large curvature and coreless bending forming die.

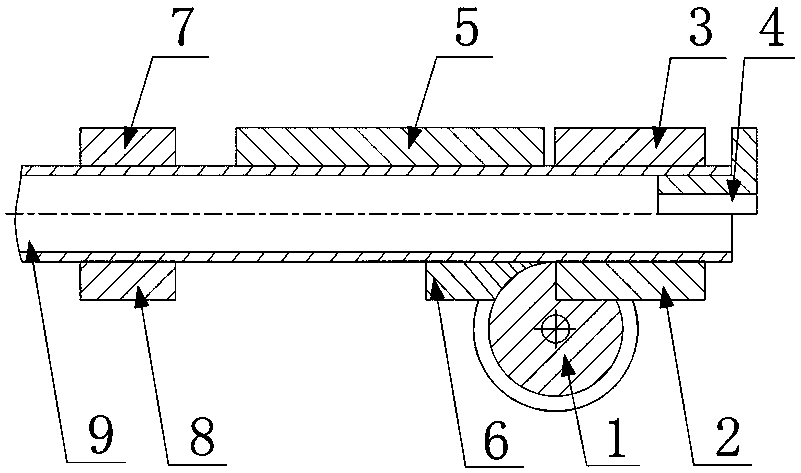

[0048] The mold described in this embodiment is obtained by improving the existing relevant pipe coreless bending forming mold. The improved mold set includes bending mold 1, inserting mold 2, clamping mold 3, cushioning mold 4, pressure mold 5, anti Wrinkle mold 6, external booster mold 7 and interior booster mold 8, its structure is as Figure 1 to Figure 6 shown.

[0049] The specific implementation scheme of this embodiment is:

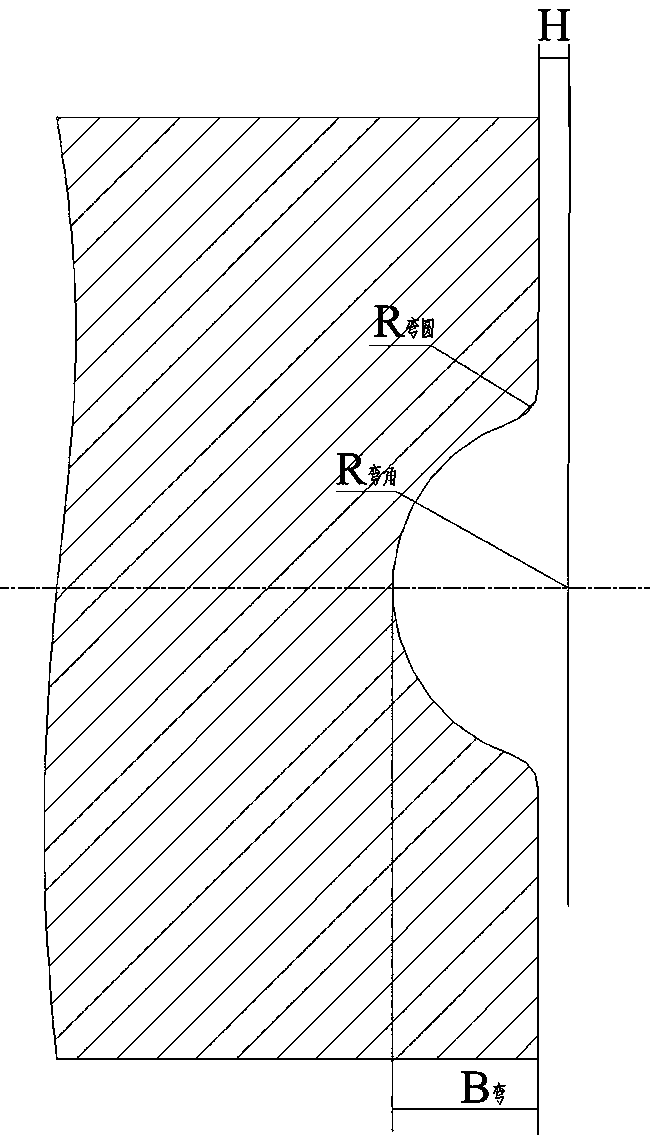

[0050] The bending die 1 is a circular disc with a bending die groove, such as figure 2 The bending die groove shown is an improved optimized groove suitable for coreless bending forming of thin-walled steel pipe with large curvature (small bending radius), where: R 弯圆 =14.64mm, B 弯 =14.12mm, R 弯角 = 1.6mm;

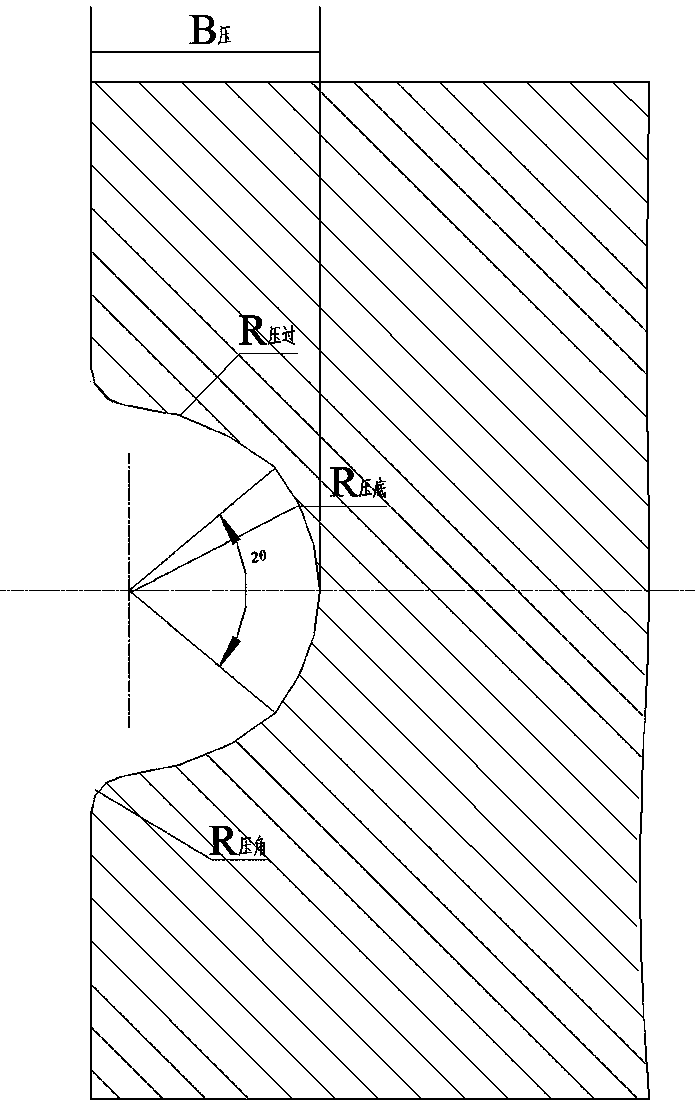

[0051] The buffer mold 4 is a half mold, and the half mold is made up of a hollow semi-cylindrical mol...

Embodiment 2

[0058] This embodiment uses the pipe bending die described in Embodiment 1 to carry out the bending forming method of a double-assist large-curvature (small bending radius) coreless curved thin-walled steel pipe.

[0059] In this embodiment, the material is 0Cr18Ni9, and the pipe specification is a stainless steel pipe of Φ30×t1.20, that is, the outer diameter of the pipe is 30mm, the original wall thickness is 1.20mm, the relative wall thickness is t / D=0.04, and the relative bending radius R / D = 1.1.

[0060] like Figure 7 As shown, the specific implementation process includes the following steps:

[0061] S1, the assembly and debugging of the mold. When assembling and debugging related moulds, install the bending die 1, inserting die 2, clamping die 3, cushioning die 4, pressure die 5, anti-wrinkle die 6, external boosting die 7 and internal boosting die 8 on the bending die in sequence. On the pipe machine, turn on the pipe bender after installation, and adjust the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com