Device and method for stamping and etching micro-parts based on high-pressure submerged cavitation water jet

An etching device and water jet technology are applied in the fields of machinery manufacturing, special processing and material forming to achieve the effects of high processing precision, low strength loss and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

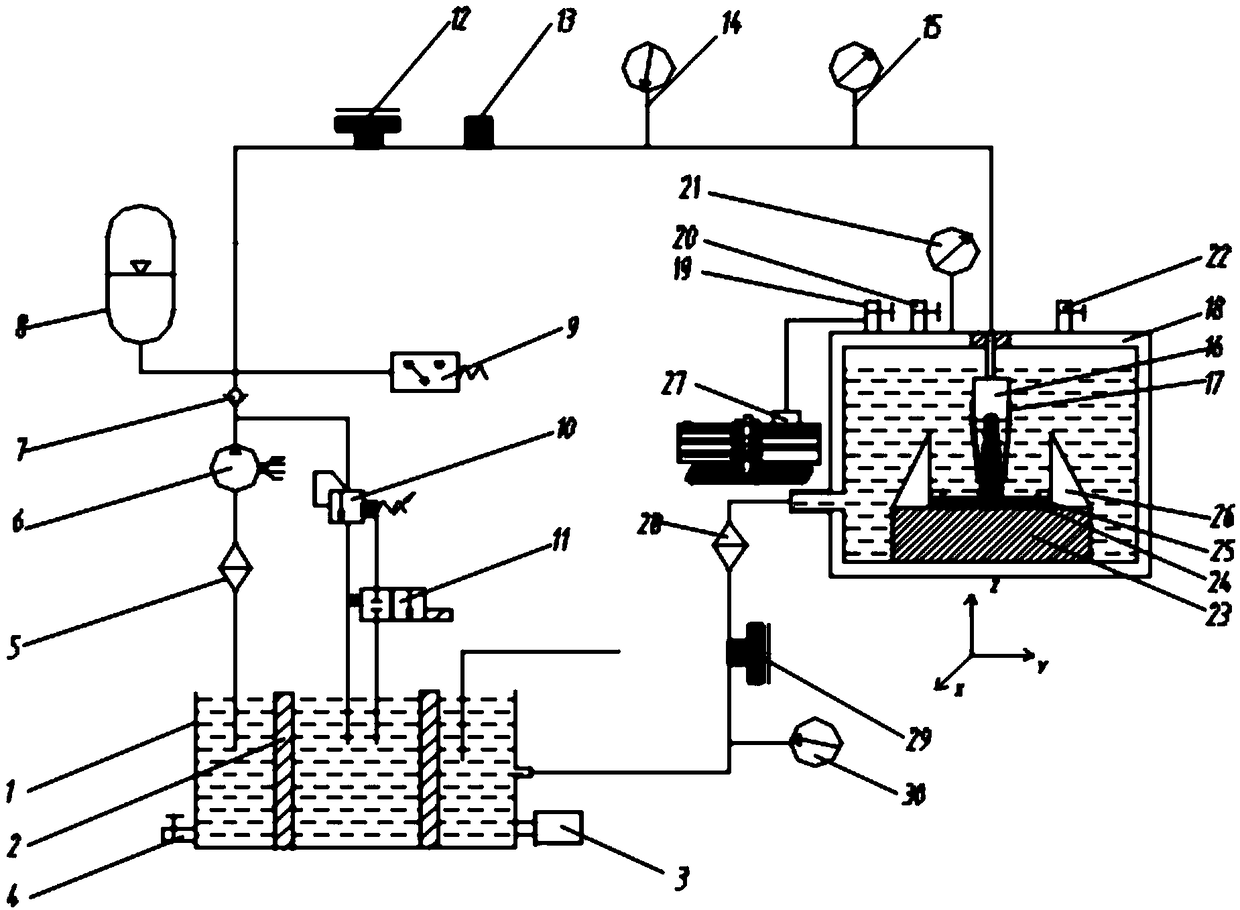

[0053] In conjunction with the accompanying drawings, a micro-part stamping and etching device based on high-pressure submerged cavitation water jet (taking stamping as an example, it includes the following steps:

[0054] (1) if Figure 5 As shown, the stamping die 25 is placed on the three-coordinate workbench 23, on which the micro-parts that need to be stamped are arranged, and the stamping die and the micro-parts are positioned and clamped by the positioning clamping device 26;

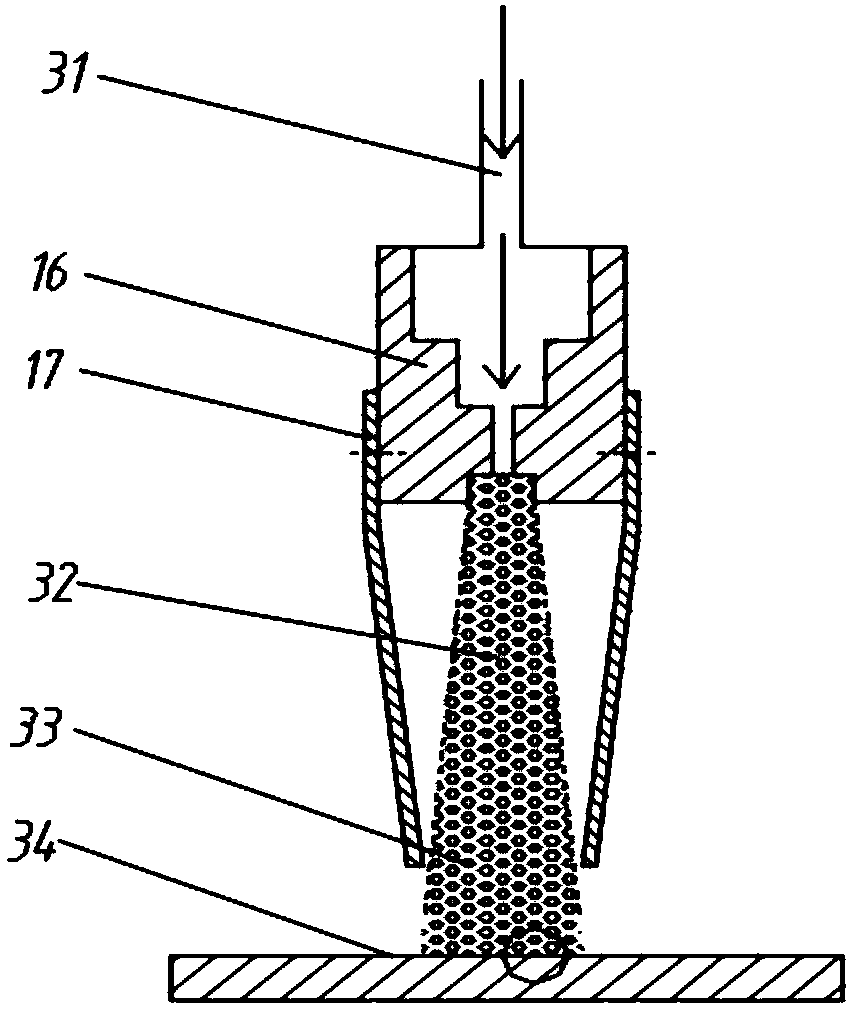

[0055] (2) Select a suitable cavitation water jet guide device 17 according to the shape to be stamped by the micro parts, and connect it with the cavitation nozzle 16 by screws; select a convergent guide device in this embodiment;

[0056] (3) Open the water inlet valve 22, so that the high-pressure vessel 18 is filled with water and the water surface exceeds the height d of the upper edge of the cavitation nozzle 16 1 =2cm, open the booster valve 19 and open the high-pressure air compressor 27...

Embodiment 2

[0065] A micro-part stamping and etching device based on high-pressure submerged cavitation water jet is described in detail in conjunction with the accompanying drawings. Taking etching processing as an example, it includes the following steps:

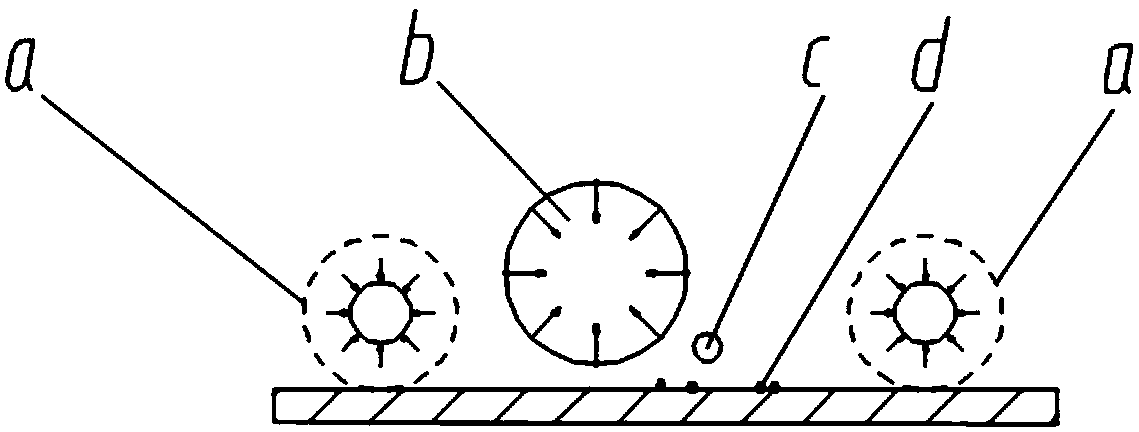

[0066] (1) if Figure 7 As shown, the micro-parts to be etched are placed on the three-coordinate workbench 23, and the etching mask 25 is arranged on it, and the etching mask and the micro-parts are positioned and clamped by the positioning clamping device 26;

[0067] (2) if Figure 7 As shown, according to the shape of the micro-parts to be etched, select a suitable cavitation water jet guide device 26, and connect it to the cavitation nozzle 16 through screws; in this embodiment, a convergent guide device is selected in the process of first etching the keyway;

[0068] (3) Open the water inlet valve 22, so that the high-pressure vessel 18 is filled with water and the water surface exceeds the height d of the upper edge of the cavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com