Square coppered groove hole drilling method

A drilling method and copper groove technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problem that the size and shape of the slot cannot meet the customer's quality requirements, the quality of the hidden danger is large, and the slot Offset and other issues, to achieve the effect of saving costs, saving enterprise costs, and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

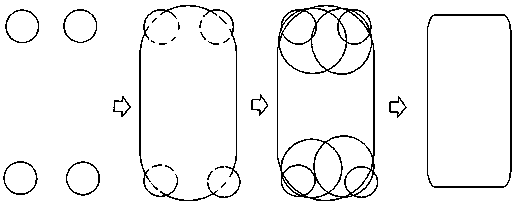

[0013] see figure 1 , the square of the present invention has the copper slot hole drilling method, is to drill four guide holes earlier on the four corners of the square slot hole, then drills the elliptical slot hole with a drill bit equal to the slot width, and uses the last Use a drill bit tangent to the two sides of the corner to drill a round hole for edge trimming. This drilling method can achieve the ideal effect of a square slot hole, and all steps are completed on the drilling machine, which can be completed in one positioning, effectively avoiding two Various problems caused by secondary positioning errors.

[0014] In the specific implementation, first of all, according to the design size of the copper slot hole, select a suitable drill tip, generally choose a drill tip of 0.5-0.6 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com