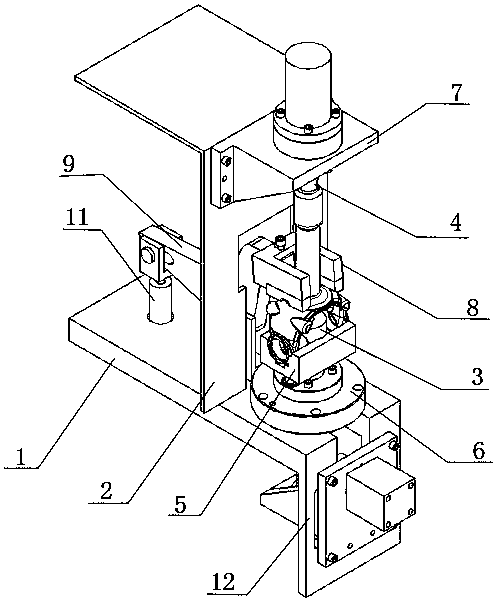

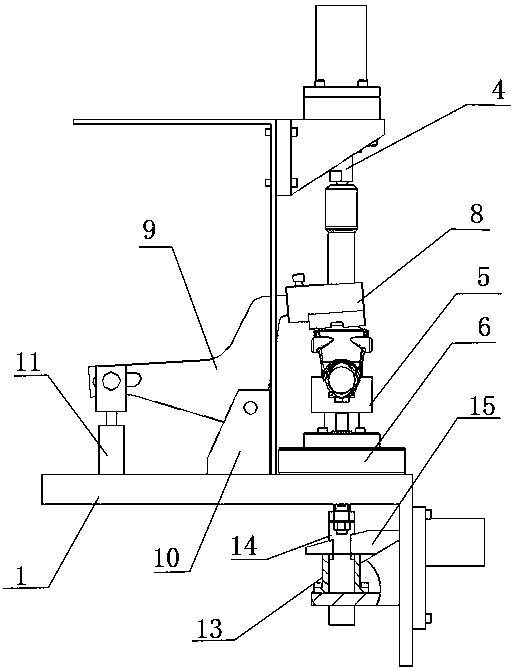

Central hole positioning fixture for drilling lug hole of spline shaft fork

A spline shaft fork, positioning fixture technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of poor blank surface consistency, large center height dimensional changes, machining errors, etc., to avoid machining errors and ensure the position. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] As shown in the figure: a center hole positioning fixture for spline shaft fork drilling ear holes, including base 1, clamp body support plate 2, fixed top 3, movable top 4, V-shaped block 5, pressing device and V-shaped The block adjustment device 12, the base 1 is horizontally installed on the processing machine tool, the clamp body support plate 2 is vertically arranged with the base 1, the clamp body support plate 2 is fixed with a movable top seat 7 by bolts, and a hydraulic cylinder and a hydraulic cylinder are installed on the movable top seat 7. The movable center 4 is driven and controlled by a hydraulic cylinder; the base is fixed with a fixed center seat 6 by bolts, the fixed center 3 is mounted on the fixed center seat 6, and the movable center 4 and the fixed center 3 are coaxially arranged and the centers are opposite to each other. ; The V-shaped block 5 is movably installed on the shaft body of the fixed top 3, the length direction of the V-shaped groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com