Silo and diversified silo material storage system

A storage system and silo technology, applied in the field of silos, can solve the problems of poor material discharge, bridging and arching, silo discharge speed and quality constraint productivity, etc., to achieve the effect of improving speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

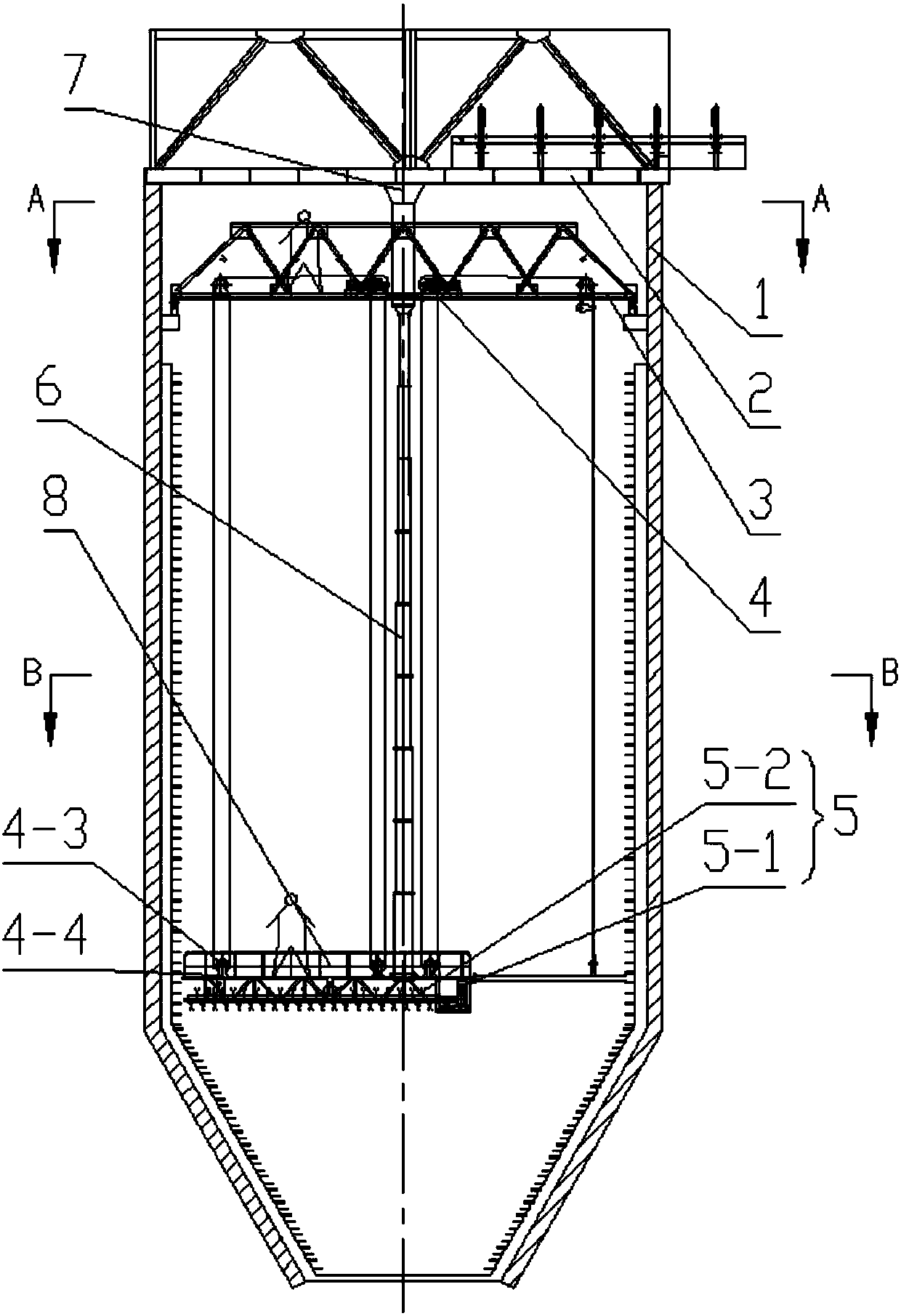

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

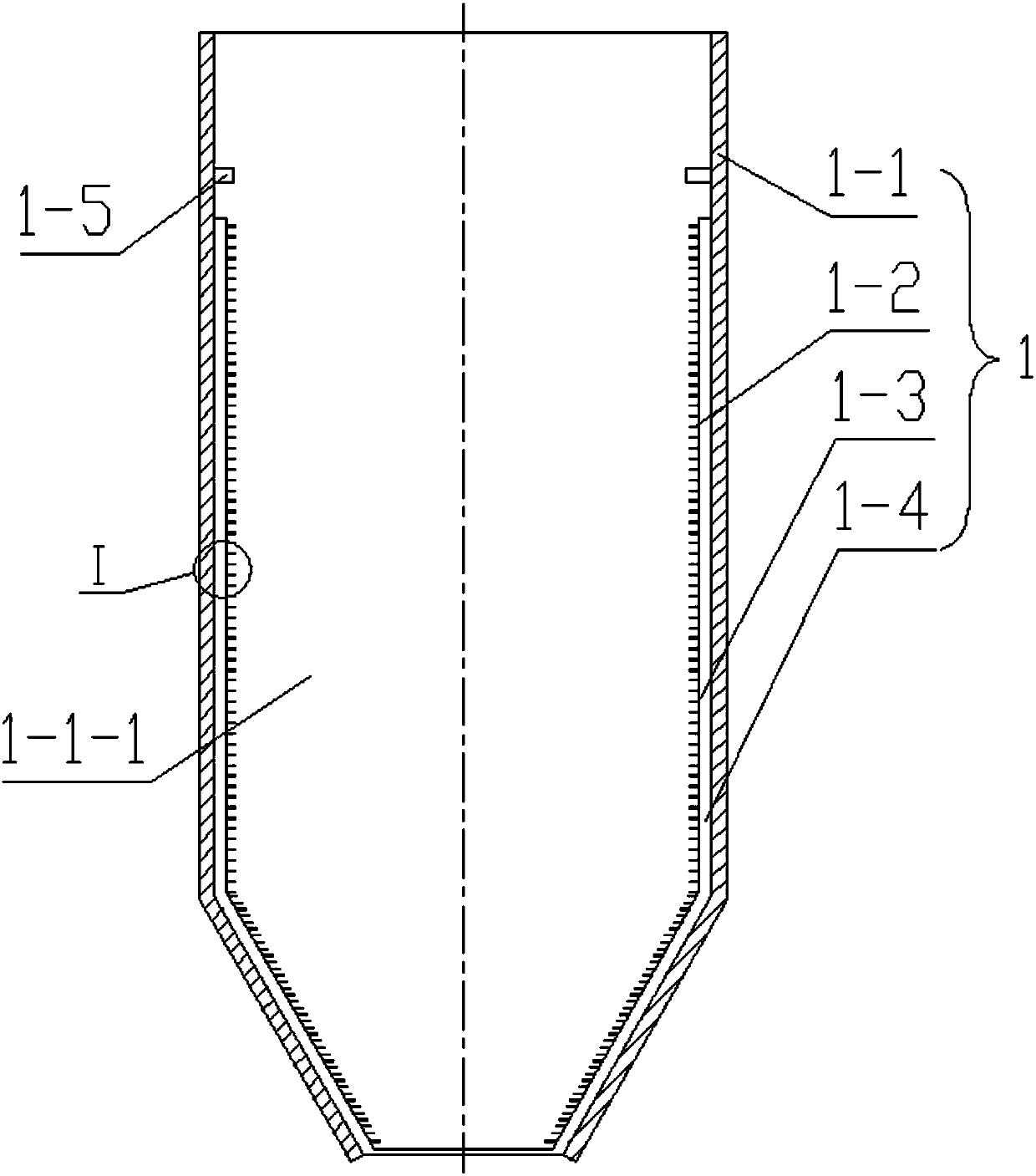

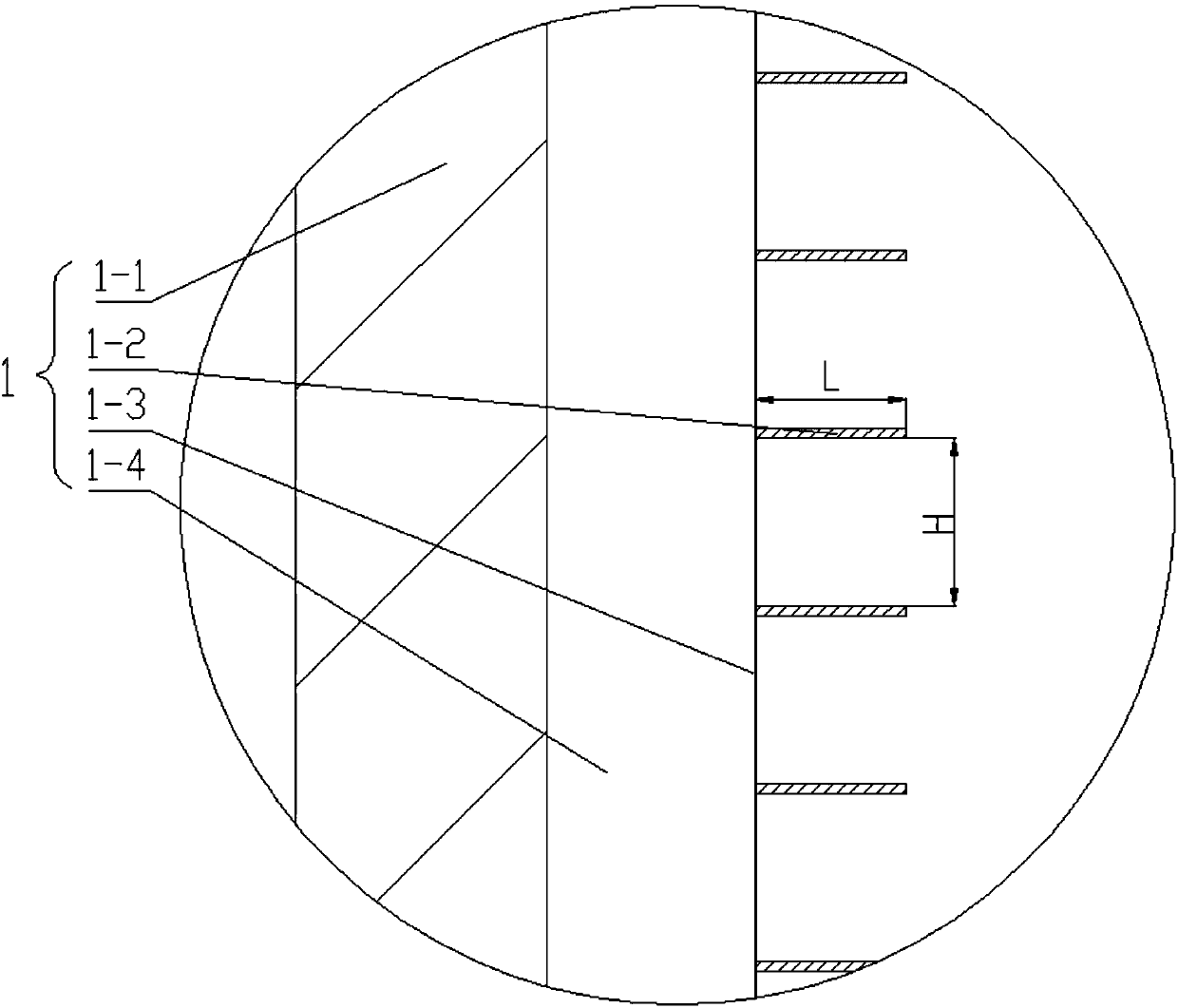

[0028] In one aspect, the invention provides a silo 1, such as figure 1 with figure 2 As shown, including the silo body 1-1, the silo body 1-1 is provided with a cavity 1-1-1 for storing materials through up and down, and the side wall of the cavity 1-1-1 is provided with a plurality of The steel plate rings 1-2 arranged at intervals up and down, an annular cavity 1-4 is formed between all the steel plate rings 1-2 and the inner wall of the silo body 1-1, and the size and spacing of all the steel plate rings 1-2 are designed so that falling When the materials in the silo body 1-1 are accumulated in the inner space of the steel plate ring 1-2, they cannot enter the annular cavity 1-4.

[0029] In the silo 1 of the present invention, a plurality of stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com