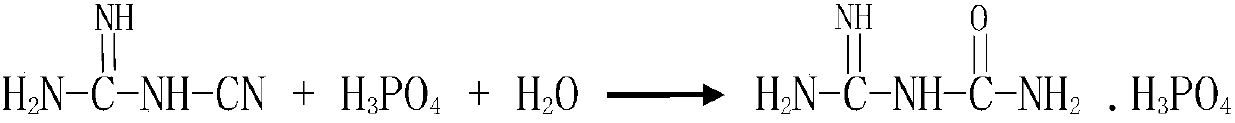

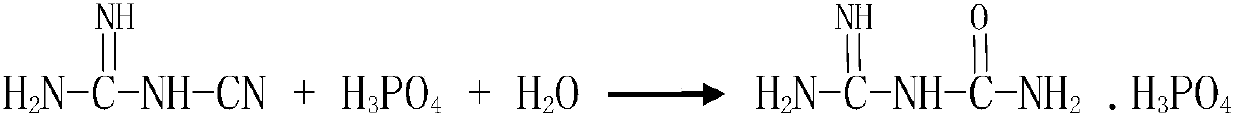

Preparation method of amidinourea phosphate

A technology of guanidinourea phosphate and dicyandiamide, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problem that the production process of guaninourea phosphate has not been optimized, and the preparation of guaninourea phosphate has not been mentioned. Process and other issues, to achieve the effect of high product purity, mild reaction conditions, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 100Kg of dicyandiamide and 200Kg of purified water into the reaction kettle and mix them well, then raise the temperature of the system to 80°C and start adding phosphoric acid aqueous solution dropwise, the dropping rate is controlled at 100L / h, after the dropwise addition, slowly raise the temperature of the reaction kettle to 100 ℃ for 8 hours, after the completion of the insulation, the system was cooled to below 20 ℃ to start centrifugation, the centrifuged solid was rinsed with ethanol, and the target product was dried to 192Kg, the total yield was 80.6%, and the detection purity was 99.4%.

Embodiment 2

[0020] Put 100Kg of dicyandiamide and 400Kg of purified water into the reaction kettle and mix them well, then raise the temperature of the system to 100°C and start adding phosphoric acid aqueous solution dropwise, the dropping rate is controlled at 150L / h, after the dropwise addition is completed, slowly raise the temperature of the reaction kettle to 100°C ℃ for 8 hours, after the completion of the incubation, the temperature of the system was lowered to below 20 ℃ to start centrifugation, the centrifuged solid was rinsed with ethanol, and the target product was dried to 181Kg, the total yield was 76%, and the detection purity was 99.3%.

Embodiment 3

[0022] Put 100Kg of dicyandiamide and 200Kg of guanylurea phosphate centrifugal mother liquor into the reaction kettle instead of purified water and mix well, then raise the temperature of the system to 80°C and start adding phosphoric acid aqueous solution dropwise, the dropping rate is controlled at 100L / h, and the dropping is completed Then slowly raise the temperature of the reaction kettle to 100°C and keep it warm for 8 hours. After the heat preservation is completed, cool the system down to below 20°C and start centrifugation. The purity is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com