Heat-resistant and abrasion-resistant stabilization roller

A wear-resistant and stable roll technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the time-consuming and troublesome assembly or disassembly, the zinc liquid cannot pass through smoothly, and the cross-sectional area of the zinc liquid flow Small and other problems, to achieve the effect of improved bonding strength, convenient assembly or disassembly, and good elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

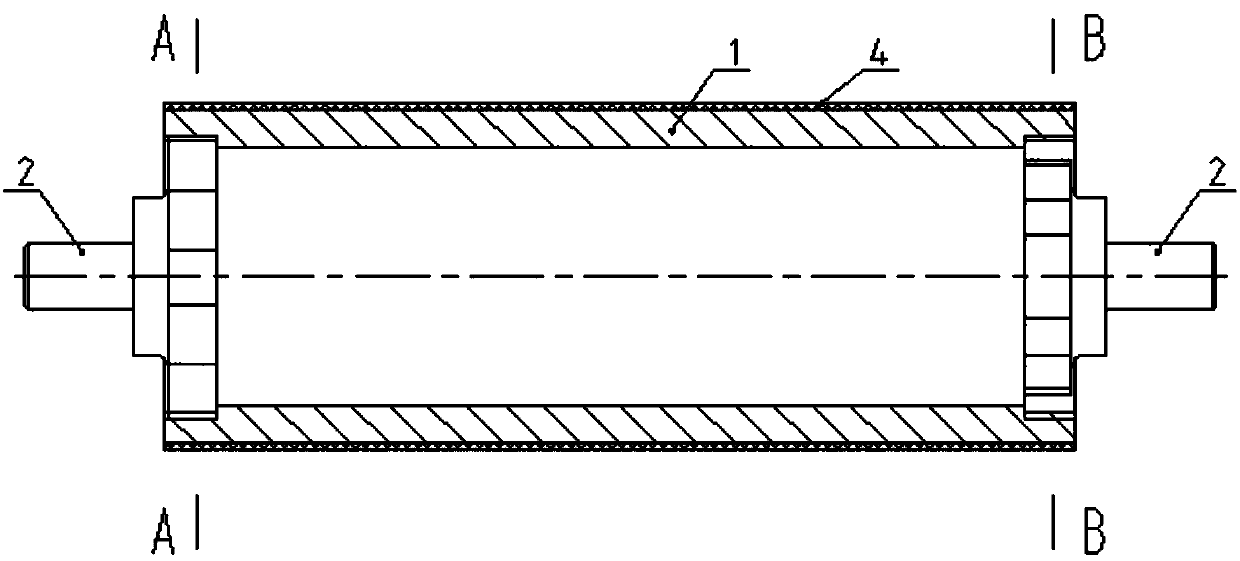

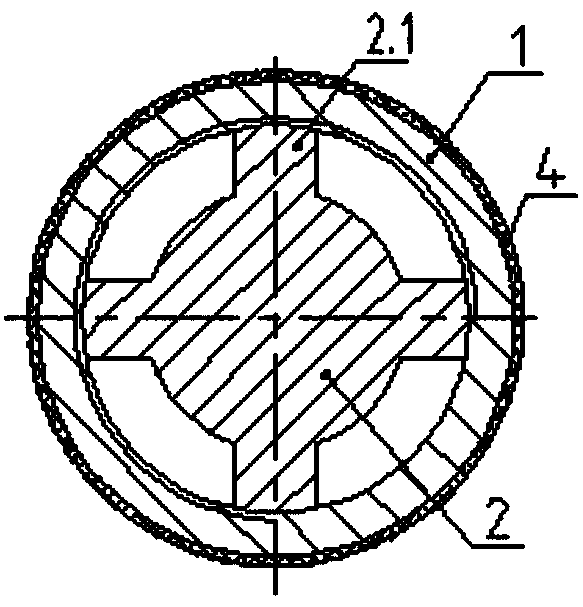

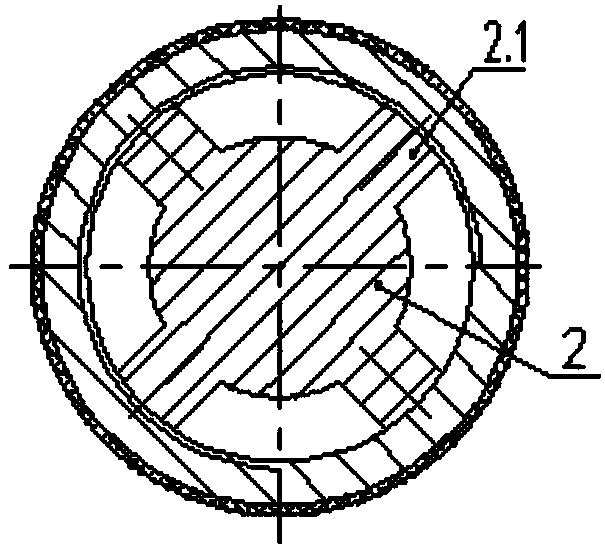

[0020] The heat-resistant and wear-resistant stabilizing roller shown in the accompanying drawings includes a roller 1 and a roller shaft 2 connected to both ends of the roller 1; the end of the roller shaft 2 connected to the roller 1 is four webs 2.1 evenly distributed on the circumference (In other embodiments, the end connecting the roller shaft 2 and the roller 1 is a radial structure with three or more than four radial plates 2.1 uniformly distributed on the circumference); the outer circumference of the radial plate 2.1 is provided with an outer Screw thread, threaded connection with the inner threaded hole at the end of roller 1.

[0021] The surface of the roller 1 is surfacing and sprayed with a cermet coating 4 .

[0022] The webs 2.1 of the rollers 2 at both ends are staggered in the circumferential direction with the centr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap