Liquid medium deceleration strip

A technology of liquid medium and speed bumps, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of large damage to the road surface, noise, bumpy feeling, etc., to ensure the basic functions and reduce the difficulty of construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

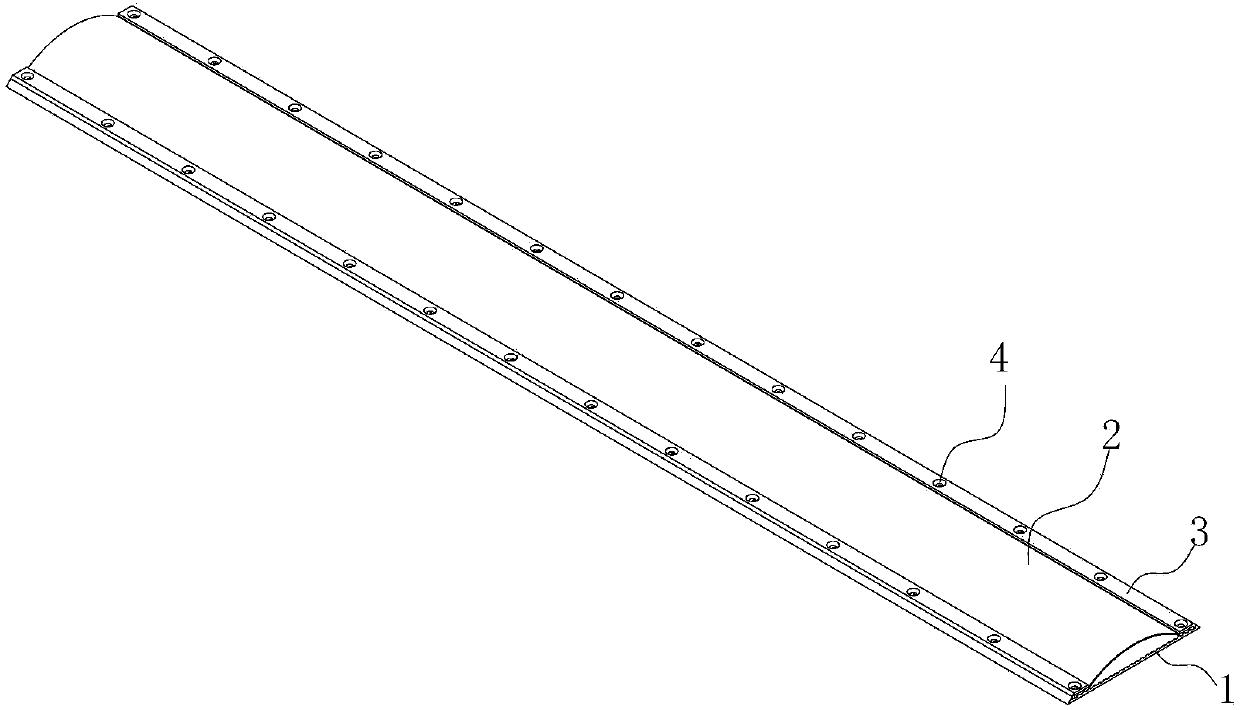

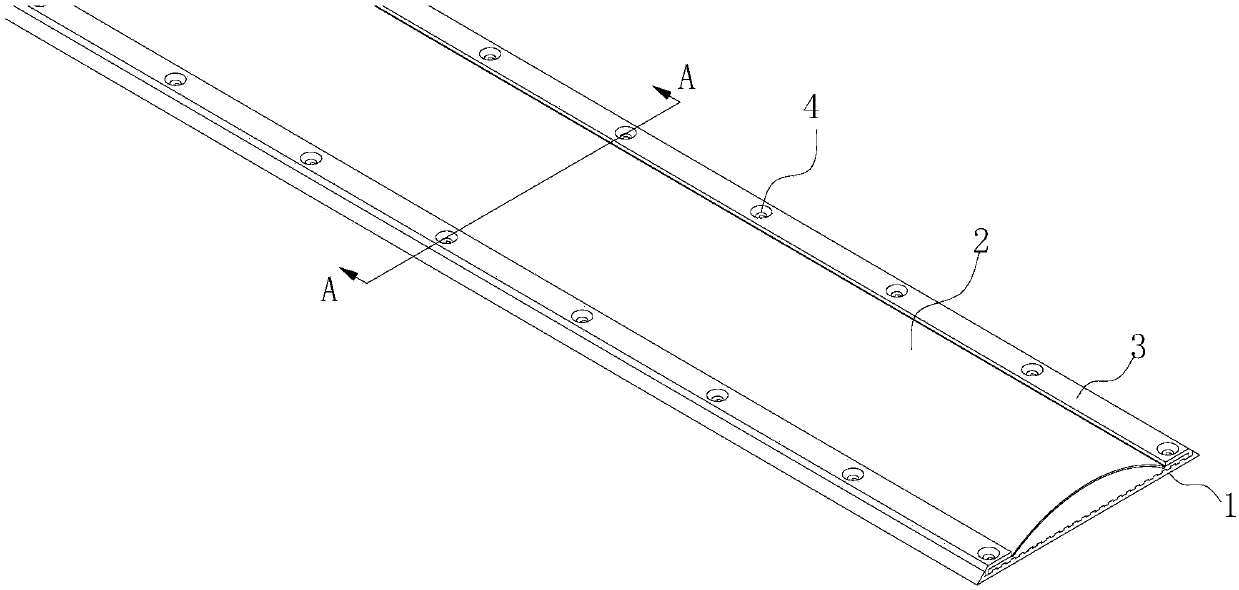

[0025] See attached figure 1 - attached Figure 6 , a liquid medium speed bump of the present invention includes:

[0026] bottom plate 1;

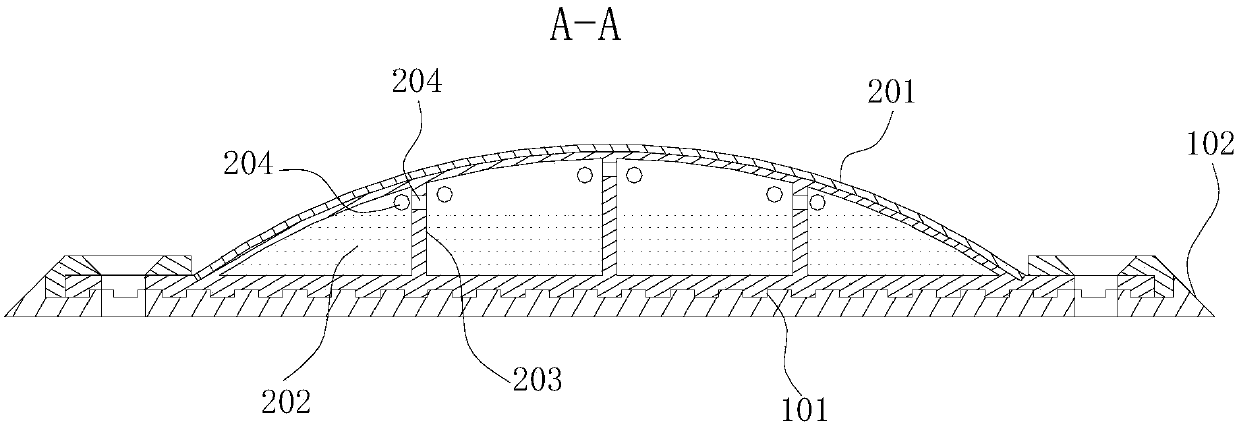

[0027] The inside of the base plate 1 is a hollow deceleration body 2, and the interior of the deceleration body 2 is intersected with a plurality of transverse isolation strips 202 and a plurality of longitudinal isolation strips 203 to form a plurality of cavities. Each transverse isolation strip 202 and A plurality of overflow holes 204 are evenly arranged on the upper part of each longitudinal isolation belt 203, so that two adjacent cavities are connected, and liquid is arranged in the cavity, and the overflow holes 204 ensure the flow of liquid in the two adjacent cavities , the distance between two adjacent lateral isolation belts 202 is a wheel width, ensuring that the liquid in the cavity corresponding to the pressurized position can flow into the adjacent cavity;

[0028] As well as the pressing plate 3 arranged on both sides...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that: the liquid is provided in the cavity, specifically: the cavity provided with liquid in the horizontal direction and the cavity without liquid are arranged alternately, the cavity provided with liquid in the vertical direction and the cavity without liquid The cavities are staggered.

[0038] The working principle of this embodiment is: when the wheel is pressed at a low speed, the liquid will be gradually surged forward, and when the height of the overflow hole 204 on the horizontal isolation zone 202 and the longitudinal isolation zone 203 corresponding to the pressurized cavity is lower than that of the liquid When the surface height is high, the liquid will be forced to flow into the front and side cavities from the overflow hole 204 and remain in the adjacent front and side cavities. Pass, when the wheel rolls over other positions again, the same principle is used to achieve deceleration; when the whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com