Air filter assembly

An air filter and assembly technology, used in fuel air filters, intake mufflers, combustion air/combustion-air treatment, etc., can solve the problems of limited service life of filter elements, dirty filter elements, etc. The effect of air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

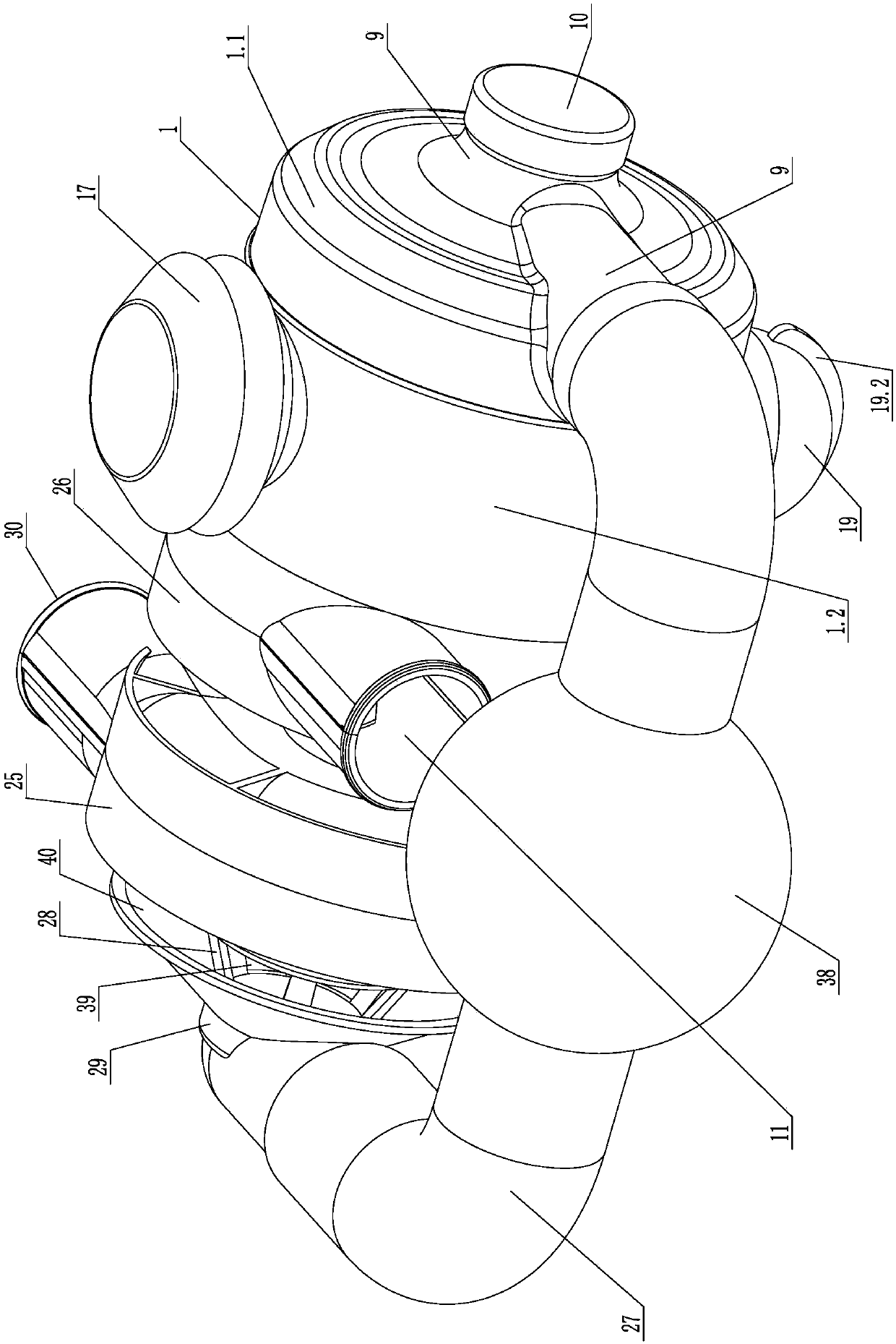

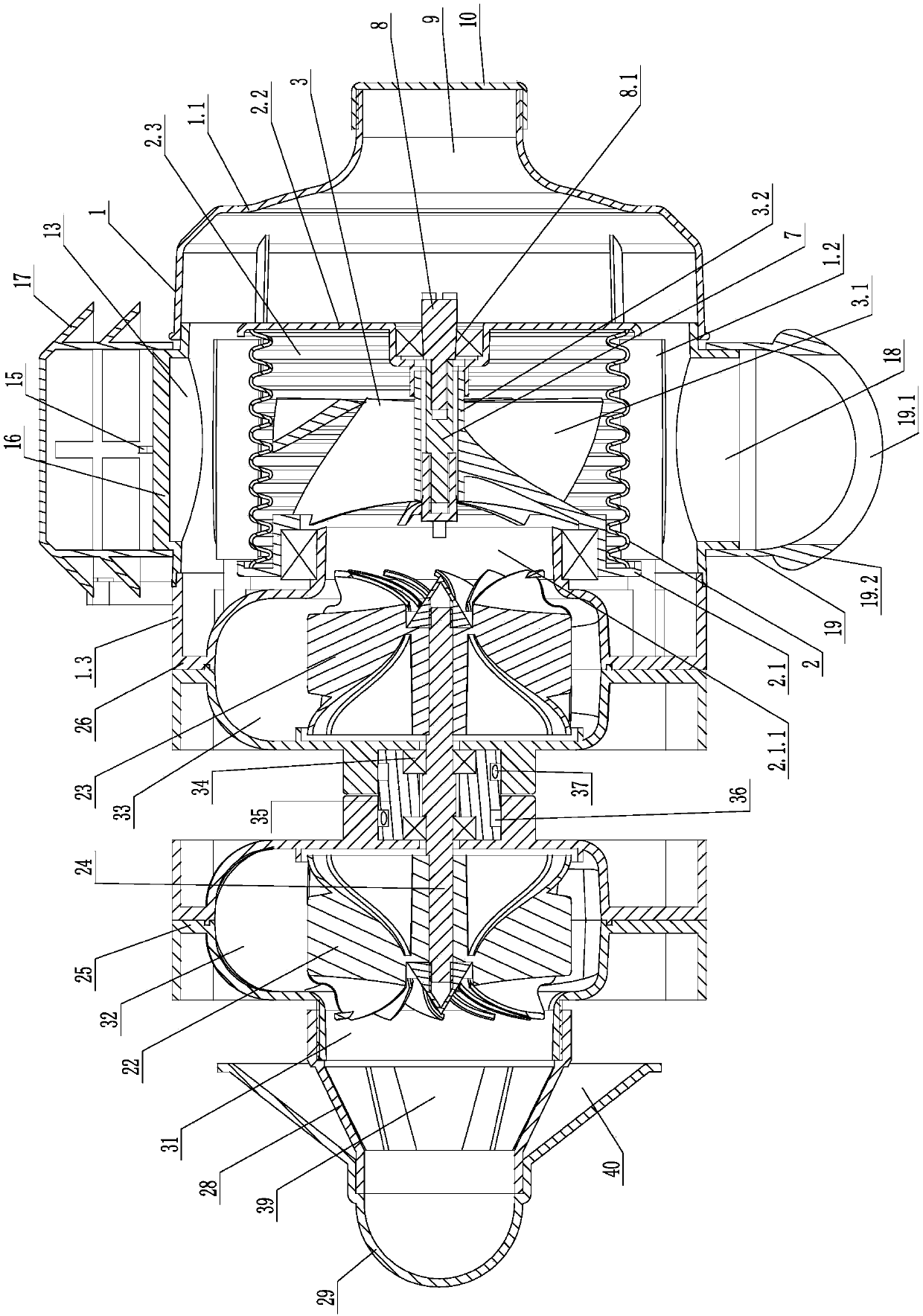

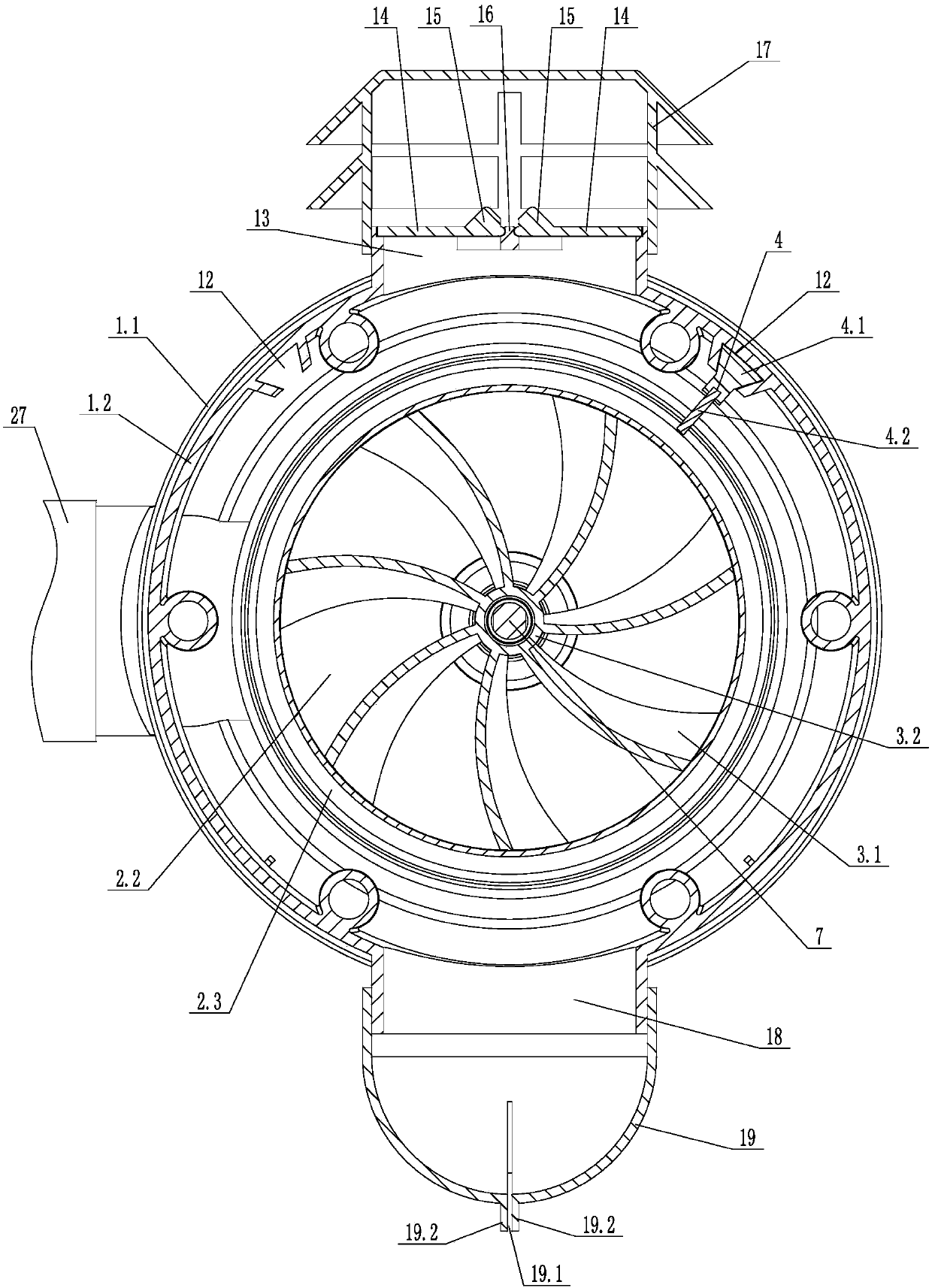

[0042] Such as Figure 1 to Figure 11 As shown, the air filter assembly of the present invention includes a housing 1, a first impeller 22, a second impeller 23, a first rotating shaft 24, a first impeller cover 25, a second impeller cover 26, a scraper 4, and a first bearing 5. The second bearing 6, the fixed shaft 7, the locking bolt 8, the connecting pipe 27, the sewage pipe 28, the air guide joint 29, and the cylindrical filter element 2 arranged in the inner cavity of the housing 1, the first impeller The cover 25 is provided with a first cavity 32 having a first air inlet 30 and a first air outlet 31, and one end of the first rotating shaft 24 extends into the first cavity 32 through the first impeller cover 25, and the first impeller 22 is located in the first cavity 32, and is rotatably connected with the first impeller cover 25 through the first rotating shaft 24, and the second impeller cover 26 is connected at one end of the housing 1, and the second impeller cover ...

Embodiment 2

[0045] The main difference between this embodiment and Embodiment 1 is that the structure of the drive mechanism for driving the filter element 2 to rotate is different, specifically: Figure 12 indivual Figure 13As shown, the driving mechanism includes a second rotating shaft 41, the second rotating shaft 41 is located in the housing 1, the filter element 2 is connected to the second rotating shaft 41, and one end of the second rotating shaft 41 is coaxially connected with the first rotating shaft 24 , in this embodiment, the first rotating shaft 24 and the second rotating shaft 41 are integrated, that is to say, the second rotating shaft 41 is actually the part where one end of the first rotating shaft 24 protrudes into the housing 1; the first fixing The disk 2.1 is provided with a shaft sleeve 42, the shaft sleeve 42 is connected to the second rotating shaft 41, the second fixed disk 2.2 is sleeved on the shaft sleeve 42, and is connected to the second rotating shaft 41 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com