A kind of sealing formation method of wound lead-acid battery

A technology of lead-acid battery and formation method, which is applied in the direction of lead-acid battery, lead-acid battery construction, lead-acid battery electrode, etc., which can solve the problems of increased difficulty in battery formation, prolonging battery production cycle, and small volume of electrolyte, achieving Improve the effect of simultaneous reduction of charging capacity and charging time, improvement of exposure formation, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] According to the requirements for the use of winding batteries, a certain type of 12V75Ah battery should be formed according to the following steps:

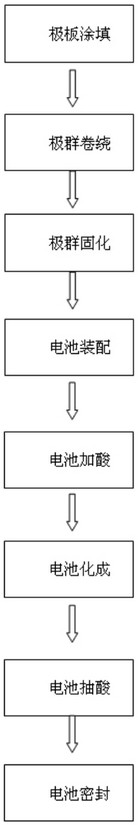

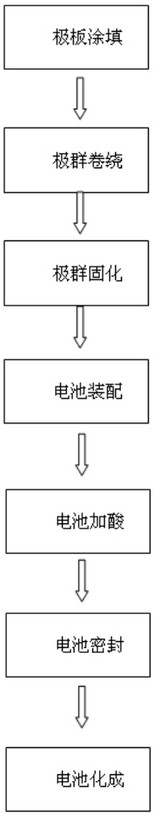

[0047] (1) if figure 2As shown in the process flow chart, the weight ratio of the amount of paste on the positive plate to the grid is controlled to be 1.25, and the weight ratio of the amount of paste to the positive electrode to the negative electrode is 1.1 when coating and filling. Ensure the consistency of the electrode group inside the semi-finished battery, and then fill the plate: fill to the thickness of the positive plate 1. 1mm, the thickness of the negative plate 1.0 mm; stack the negative plate, AGM separator, positive plate, AGM separator in order Winding and molding after placement; pole group curing: place the coiled pole group in a curing room for curing, and the temperature during the curing process should not exceed 70°C to avoid affecting the inner separator of the pole group; after curing, free lead ...

Embodiment 2

[0052] According to the requirements for the use of winding batteries, a certain type of 12V75Ah battery should be formed according to the following steps:

[0053] (1) if figure 2 As shown in the process flow chart, the ratio of the amount of paste applied to the positive plate to the weight of the grid is controlled to be 1.25, and the ratio of the amount of paste applied to the positive electrode to the negative electrode is 1.2. The consistency of the pole group inside the semi-finished battery. Then carry out electrode plate coating: coating until the thickness of the positive plate is 1.2 mm, and the thickness of the negative plate is 1.0 mm; the negative plate, AGM separator, positive plate, and AGM separator are stacked in order and then wound into shape; the pole group is cured: the The coiled electrode group is placed in a curing room for curing, and the temperature during the curing process does not exceed 70°C to avoid affecting the inner separator of the electro...

Embodiment 3

[0058] According to the requirements for the use of winding batteries, a certain type of 12V75Ah battery should be formed according to the following steps:

[0059] (1) if figure 2 As shown in the process flow chart, the ratio of the amount of paste applied to the positive plate to the weight of the grid is controlled to be 1.25, and the ratio of the amount of paste applied to the positive electrode to the negative electrode is 1.1. The consistency of the pole group inside the semi-finished battery. Then carry out plate coating: coating until the thickness of the positive plate is 1.2 mm, and the thickness of the negative plate is 1.1 mm; the negative plate, AGM separator, positive plate, and AGM separator are stacked in order and then wound into shape; the pole group is cured: the The coiled electrode group is placed in a curing room for curing, and the temperature during the curing process does not exceed 70°C to avoid affecting the inner separator of the electrode group; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com