Steady pressure type high-capacity energy accumulator

A large-capacity, accumulator technology, applied in the direction of machinery and equipment, can solve the problems of small internal space, low reliability, large design of fixtures, pumping stations, etc., to save manufacturing costs, simplify the structure, and save operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

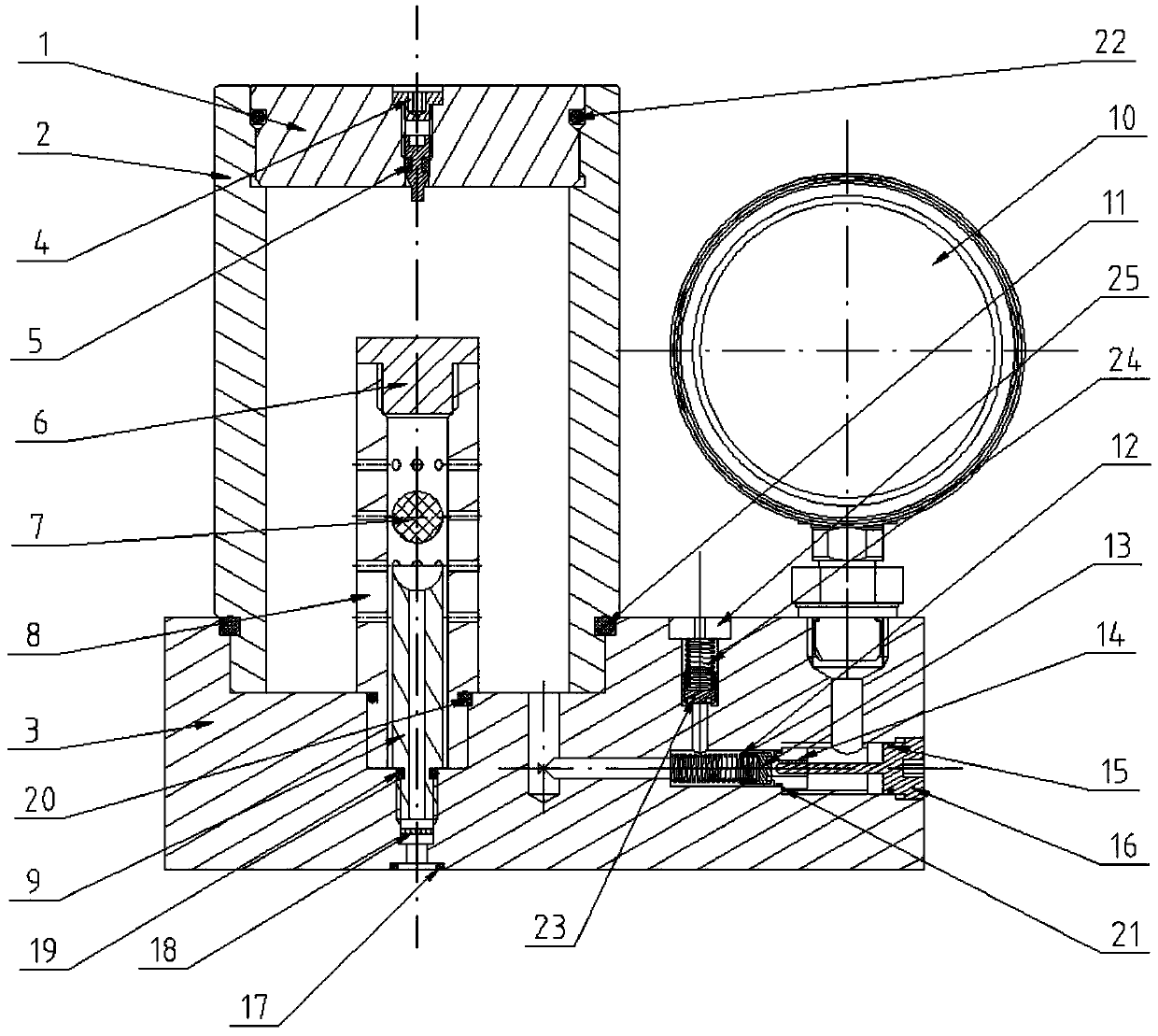

[0029] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the pressure-stabilized large-capacity accumulator includes a base 3, a cylinder 2, an upper end cover 1 with an air supply device, and a limit assembly with a function of limiting the height of the oil level. The lower end of the cylinder 2 is installed on the An upper end cover 1 is arranged on the base 3 and its upper end; the upper surface of the base 3, the inner wall surface of the cylinder body 2 and the lower surface of the upper end cover 1 form an energy storage cavity; the upper part of the energy storage cavity is gas, and the lower part is It is hydraulic oil; the limiting assembly is arranged on the base 3 in the energy storage chamber.

[0030] Further, the base 3 is provided with a four-way oil circuit, and the first to fourth branches of the four-way oil circuit communicate with the energy storage chamber, the one-way valve as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com