PRATT large-caliber butterfly valve seat seal ring replacement method

A replacement method and technology of sealing rings, applied in the direction of lift valve, valve device, material gluing, etc., can solve the problem that large-diameter butterfly valve equipment cannot be repaired, and achieve the effect of saving equipment procurement funds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] A method for replacing the sealing ring of a PRATT large-diameter butterfly valve seat, specifically comprising the following steps:

[0046] Step 1: Clean up the old valve seat

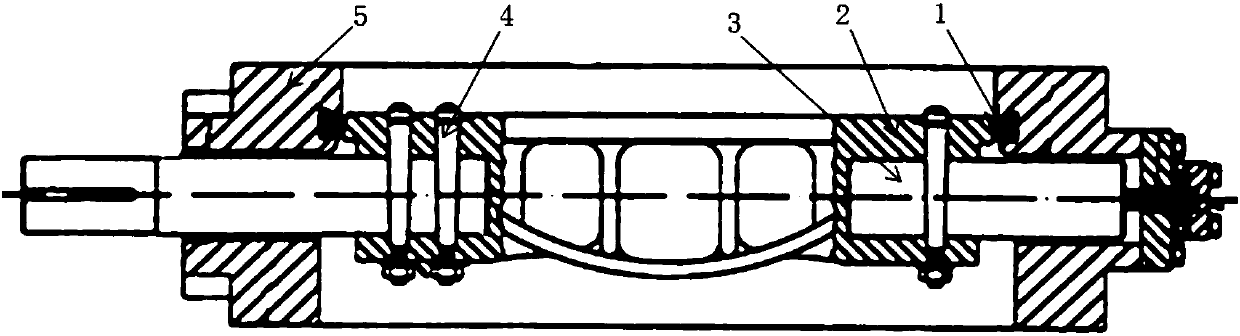

[0047] Step 1.1: Place the valve body 5 horizontally with one end of the sealing surface of the valve seat facing up, open the butterfly plate 2, and remove the old valve seat 1.

[0048] Step 1.2: Clean up waste glue and valve seat debris, keep the valve seat installation groove 8 clean, and avoid damaging the surface of the valve seat installation groove 8 during work.

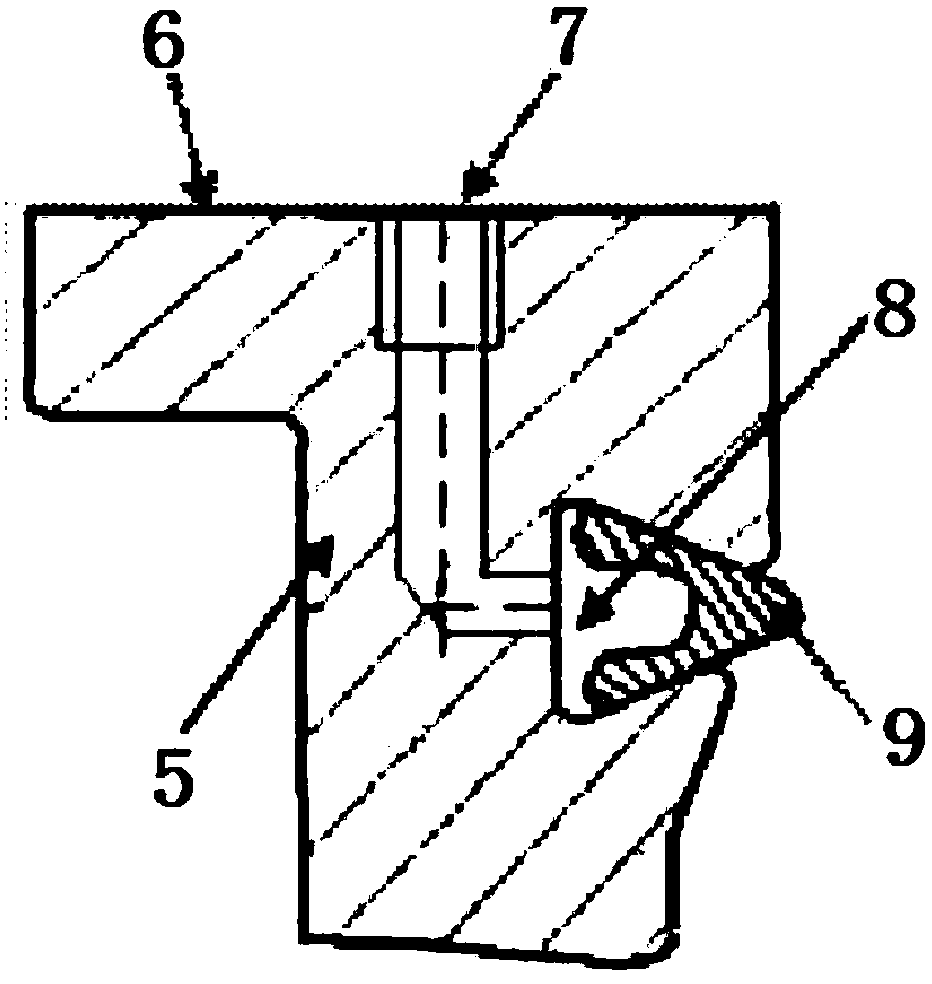

[0049] Step 1.3: Drill two glue injection holes 7 for glue injection symmetrically on the plane of the valve body flange 6 and tap them.

[0050] Step 1.4: Grind the valve seat installation groove 8 with sandpaper, so that the surface layer of the inner wall of the groove exposes the substrate and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com