CNC-controlled three-axis parallel roll collar hole pattern machining method

A processing method and pass technology, which is applied in the field of CNC-controlled three-axis parallel roller ring pass processing, can solve the problems of inventory resource occupation, long customization cycle, and inventory backlog, so as to reduce inventory, save purchase funds, and repeat high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

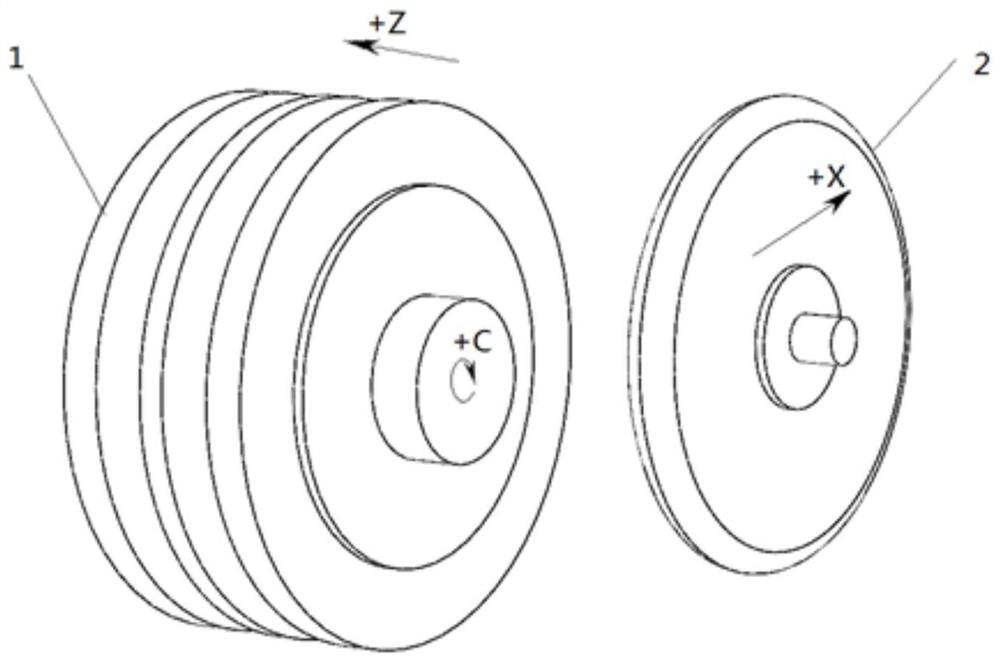

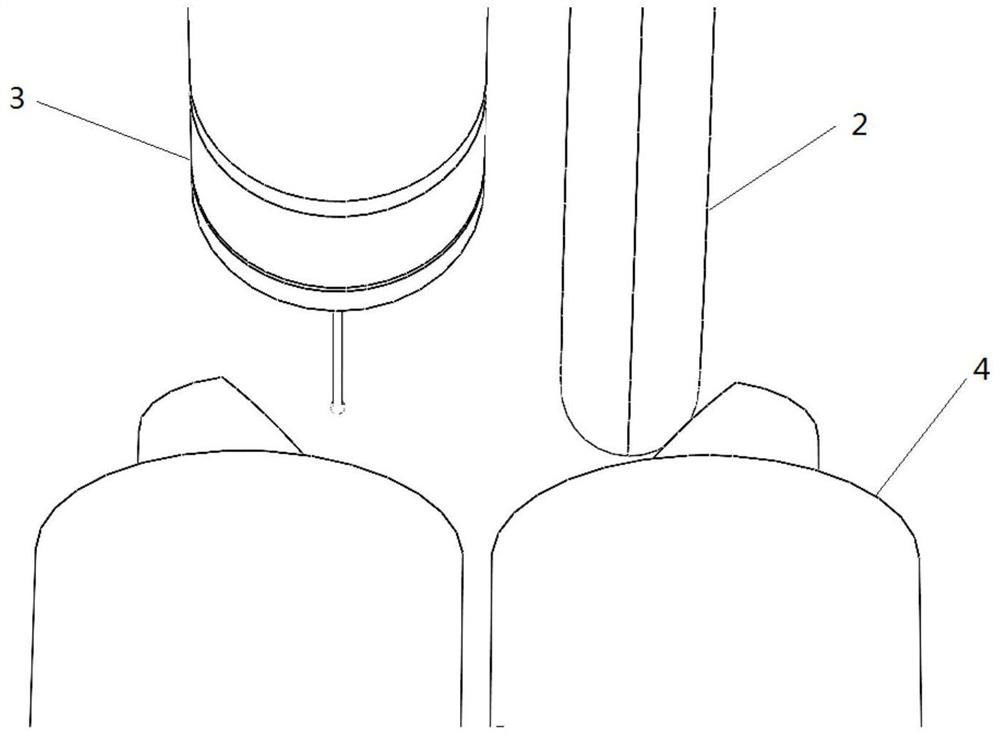

[0009] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] When processing the hole pattern of the roller ring, first turn on the main power of the grinder, restore the emergency stop button, turn on the control voltage, turn on the hydraulic system, turn on the coolant, close the safety door of the grinder, and start the grinder. Edit the processing program according to the hole type, start the automatic measurement system, and enter the grinding module.

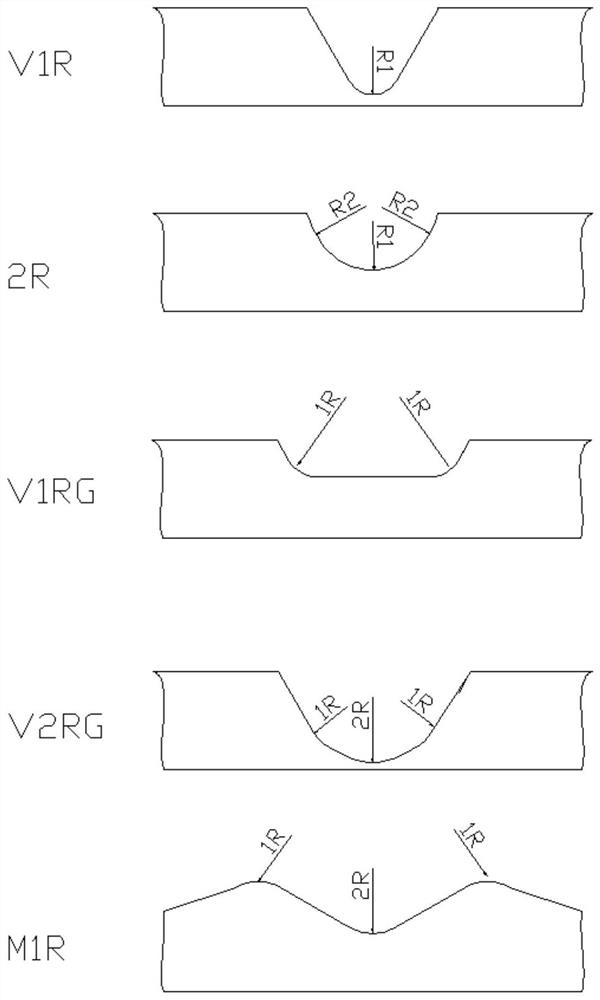

[0011] In the embodiment of the present invention, the pass type includes four Morgan pass types: V1R, 2R, V1RG, V2RG and a Kocks special-shaped pass type M1R, and the pass type parameters to be input are as follows:

[0012]

[0013]

[0014] The V1R pass is a single-arc pass, and the pass can be selected with an arc, and the arc can be ignored during rough grinding.

[0015] The 2R pass is a single circular arc connected to an arc t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com