Oil-gas separation device and method of hot oil circulation system

A separation device and circulation system technology, applied in the boiler field, can solve problems such as easy generation of air bubbles, unused heat, and influence on combustion effect, and achieve the effects of blocking sediment, simple structure, and improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

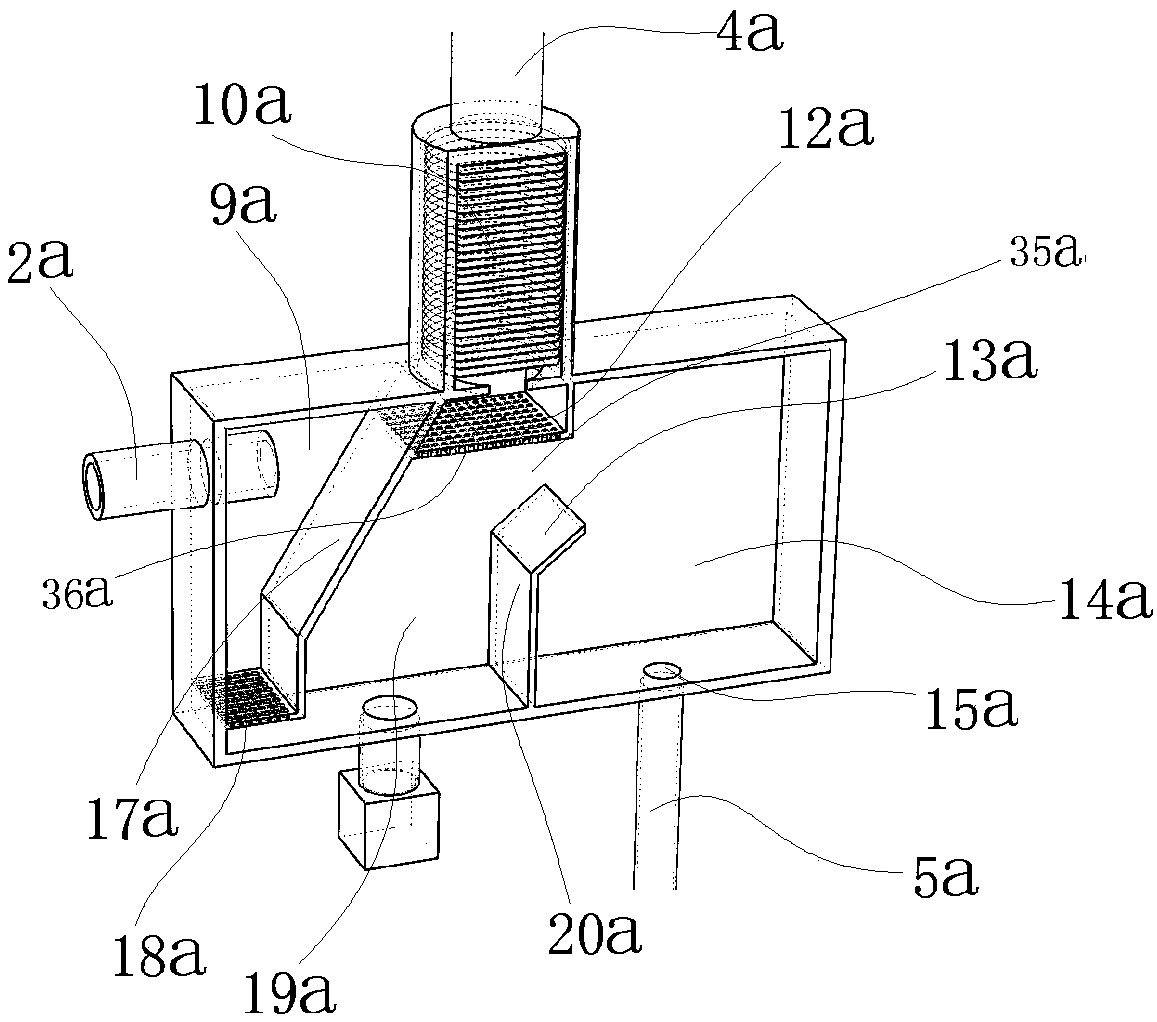

[0029] as attached Figures 1 to 4As shown, an oil-gas separation device of a hot oil circulation system is characterized in that: it includes an oil-gas separation device 3, and the oil-gas separation device 3 includes an oil-gas separation box 22a; the oil-gas separation box 22a includes a first partition plate 20a , the first partition plate 20a divides the inner cavity of the oil-gas separation box 22a into a left chamber and a right chamber 14a, the lower end of the first partition plate 20a is connected to the bottom of the oil-gas separation box 22a, and the upper end of the first partition plate 20a There is a liquid overflow channel 35a between the top of the oil-gas separation box 22a; when the liquid in the left chamber reaches the upper end of the first partition plate 20a, it will overflow into the right chamber 14a; it also includes the second partition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com