Bearing fault diagnosis method based on total variation and compensation distance assessment

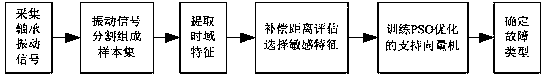

A fault diagnosis and total variation technology, applied in mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems that affect fault classification accuracy, long training time, limited processing of linear features, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

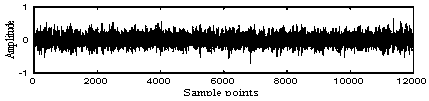

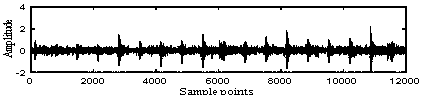

[0056] Use the multi-channel sensor to collect the vibration signal of the bearing, assuming that the 6-channel vibration sensor is used to collect the data of 5 working states of the bearing (normal, inner ring fault, outer ring fault, rolling element fault, combined fault) for 1 minute; figure 2 Figure 6 shows the vibration signals of bearing monitoring in 5 working states of normal channel, inner ring fault, outer ring fault, rolling element fault and combined fault.

[0057] Data processing extracts 200 groups as training sets and 150 groups as test sets for different working states in each direction, and each group has 3000 data points. In the time domain feature extraction, the full variation of the vibration signal is introduced on the basis of the traditional time domain feature, that is, 10 features are extracted from each set of data to form a feature set, so the 6-channel sensor constitutes a total of 60 feature sets. feature set {p c,m,k}Expressed as:

[0058] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com