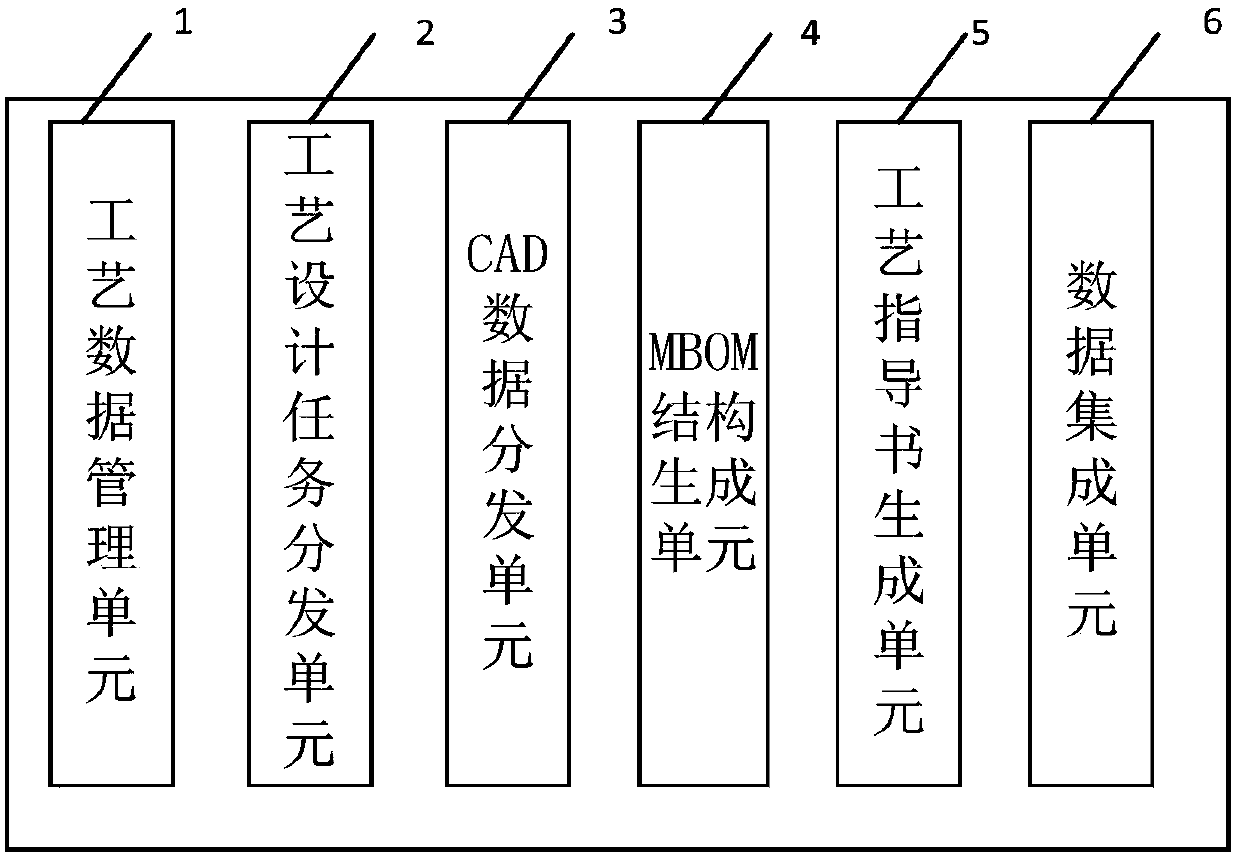

Process design collaboration management system and method based on three-dimensional model

A technology of process design and three-dimensional model, which is applied in the field of collaborative management system of process design based on three-dimensional model to achieve the effect of conveniently guiding the production and processing of factories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

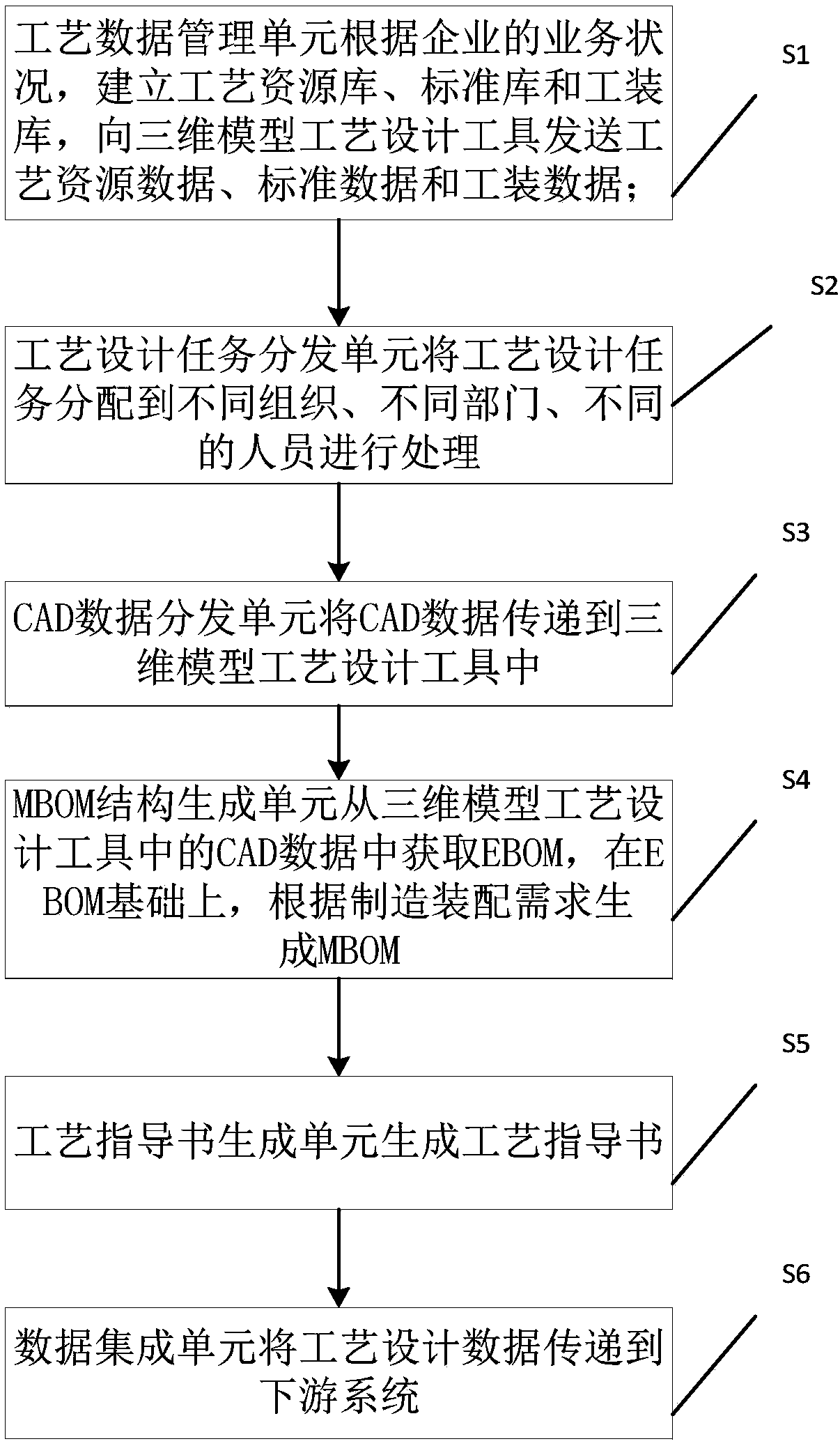

[0037] figure 2 It shows a first embodiment of the method of the above-mentioned three-dimensional model-based process design collaborative management system provided by the present invention, and the method may include the following steps:

[0038] S1: The process data management unit establishes a process resource library, a standard library, and a tooling library according to the business status of the enterprise, and sends process resource data, standard data, and tooling data to the three-dimensional model process design tool;

[0039] S2: The process design task distribution unit allocates process design tasks to different organizations, different departments, and different personnel for processing;

[0040] S3: the CAD data distribution unit transmits the CAD data to the three-dimensional model process design tool;

[0041] S4: The MBOM structure generation unit obtains the EBOM from the CAD data in the three-dimensional model process design tool, and generates the MB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com