Winding mechanism and winding method thereof

A winding mechanism and winding technology, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as incompletely solved technical problems, increase production costs, reduce production efficiency, etc., to improve production efficiency, The effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

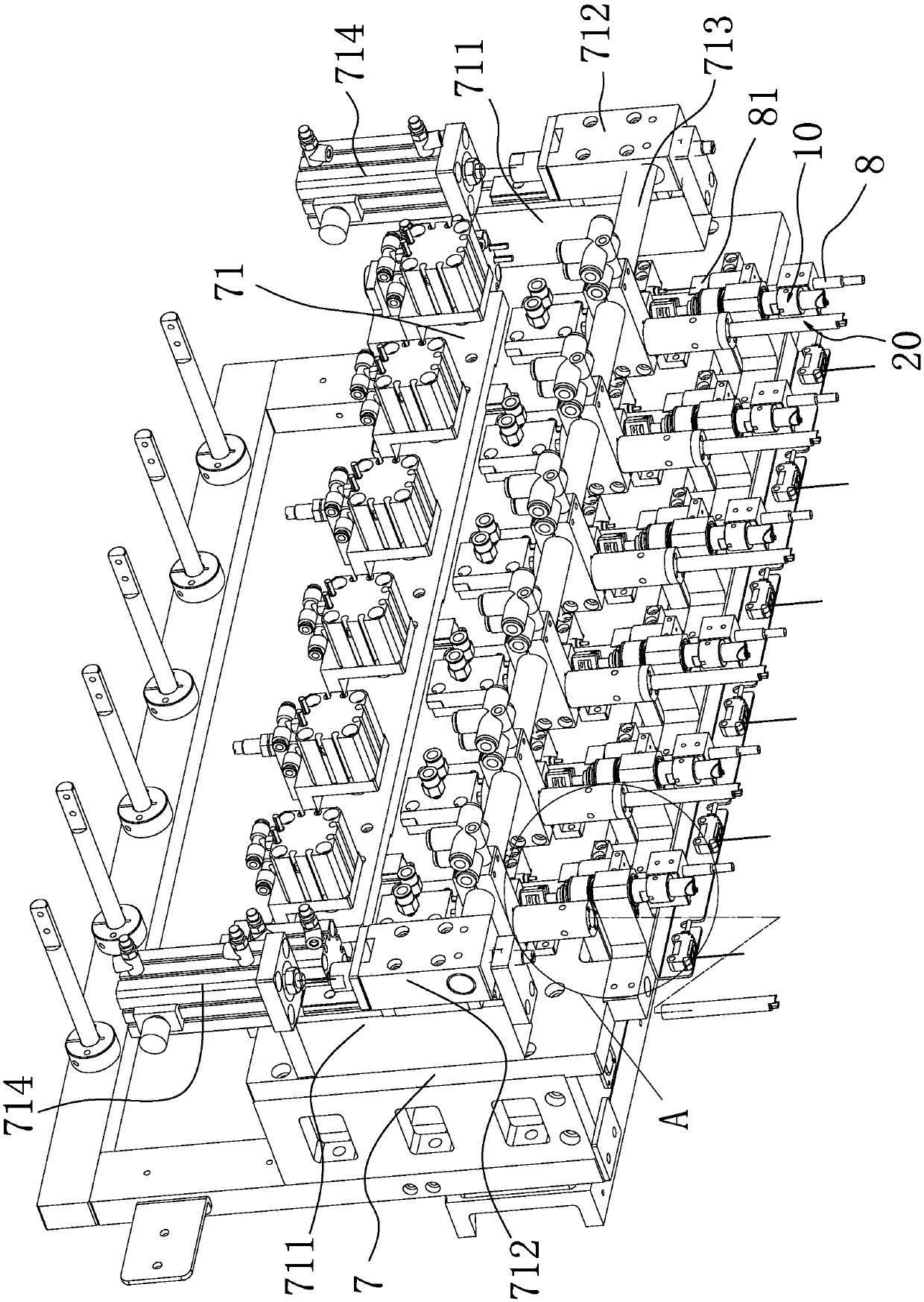

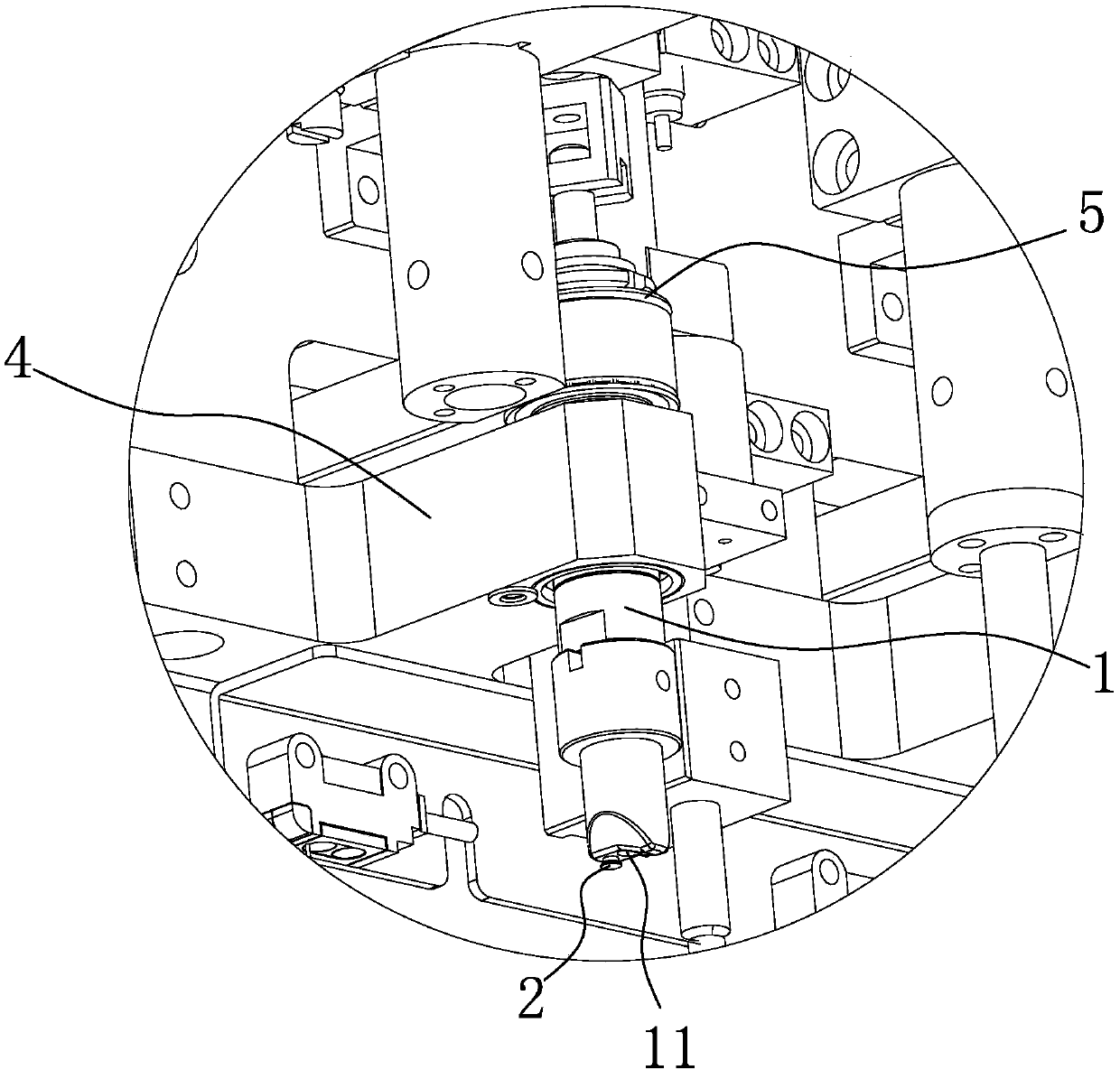

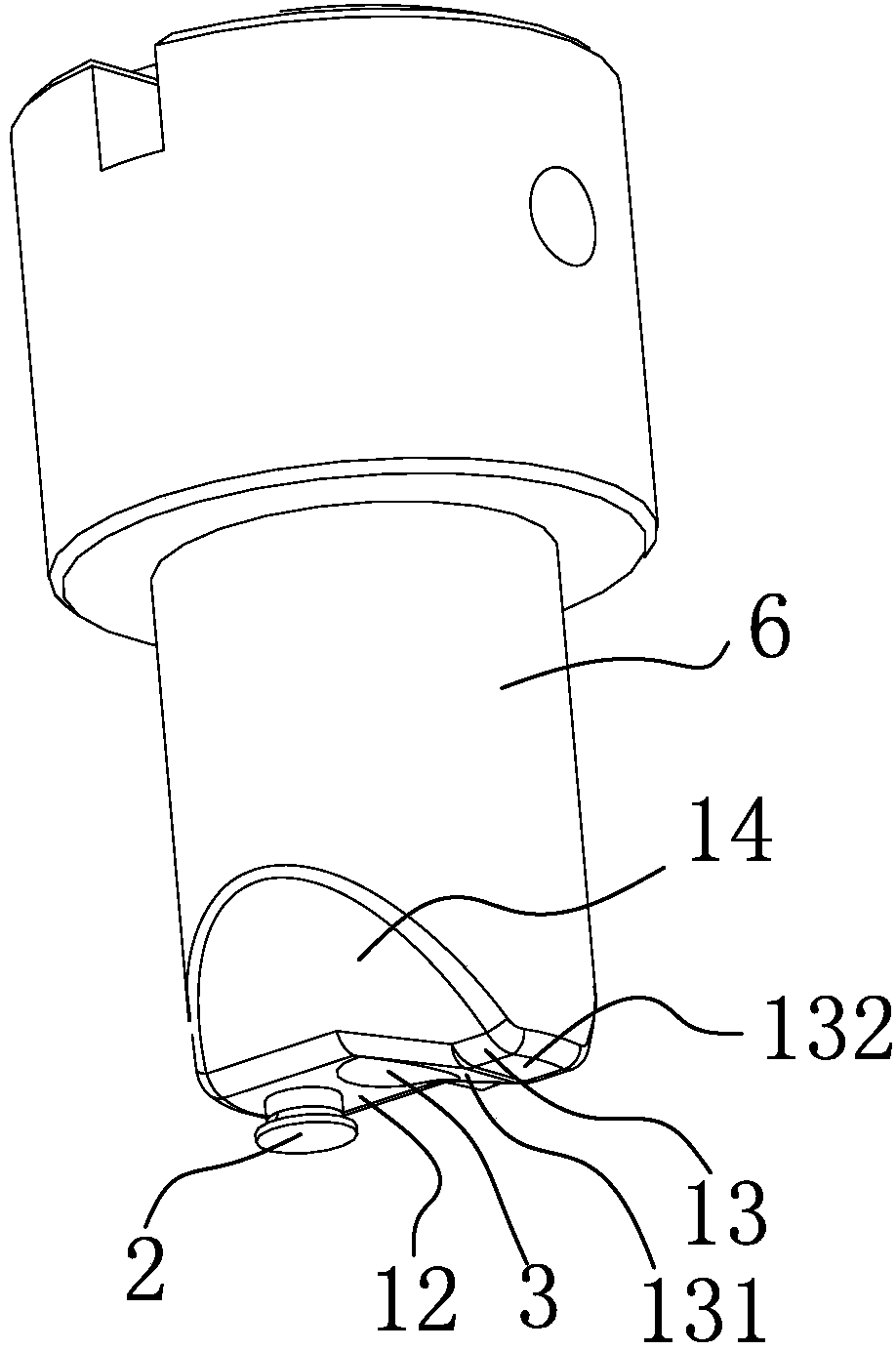

[0063] like figure 1 As shown, the winding mechanism includes a mounting plate 7, on the outer surface of the mounting plate 7 is provided a vertically arranged lift plate 71 and the lift plate 71 is connected with the lift drive device, and at least one lift plate 71 is provided on the lift plate 71. The wire inlet nozzle 8 is arranged vertically and the wire inlet nozzle 8 is connected to the wire inlet lifting drive structure 81. The lifting driving device includes sliding seats 711 arranged at both ends of the mounting plate 7, and each sliding seat 711 is slidably connected to each other. There is a sliding block 712, and a horizontally arranged lifting rod 713 is arranged between the two sliding blocks 712. The lifting rod 713 is sleeved with at least one mounting and fixing block A5 connected to the cylindrical tool rest A1 Conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com