High altitude indoor high voltage alternating current combined vacuum circuit breaker

A vacuum circuit breaker, internal high voltage technology, applied in the direction of high voltage air circuit breaker, high voltage/high current switch, circuit, etc., can solve the problems of fuse replacement, weak arc extinguishing function, large impact, etc., to improve the operating life, mechanical The effect of small impact and increased creep distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

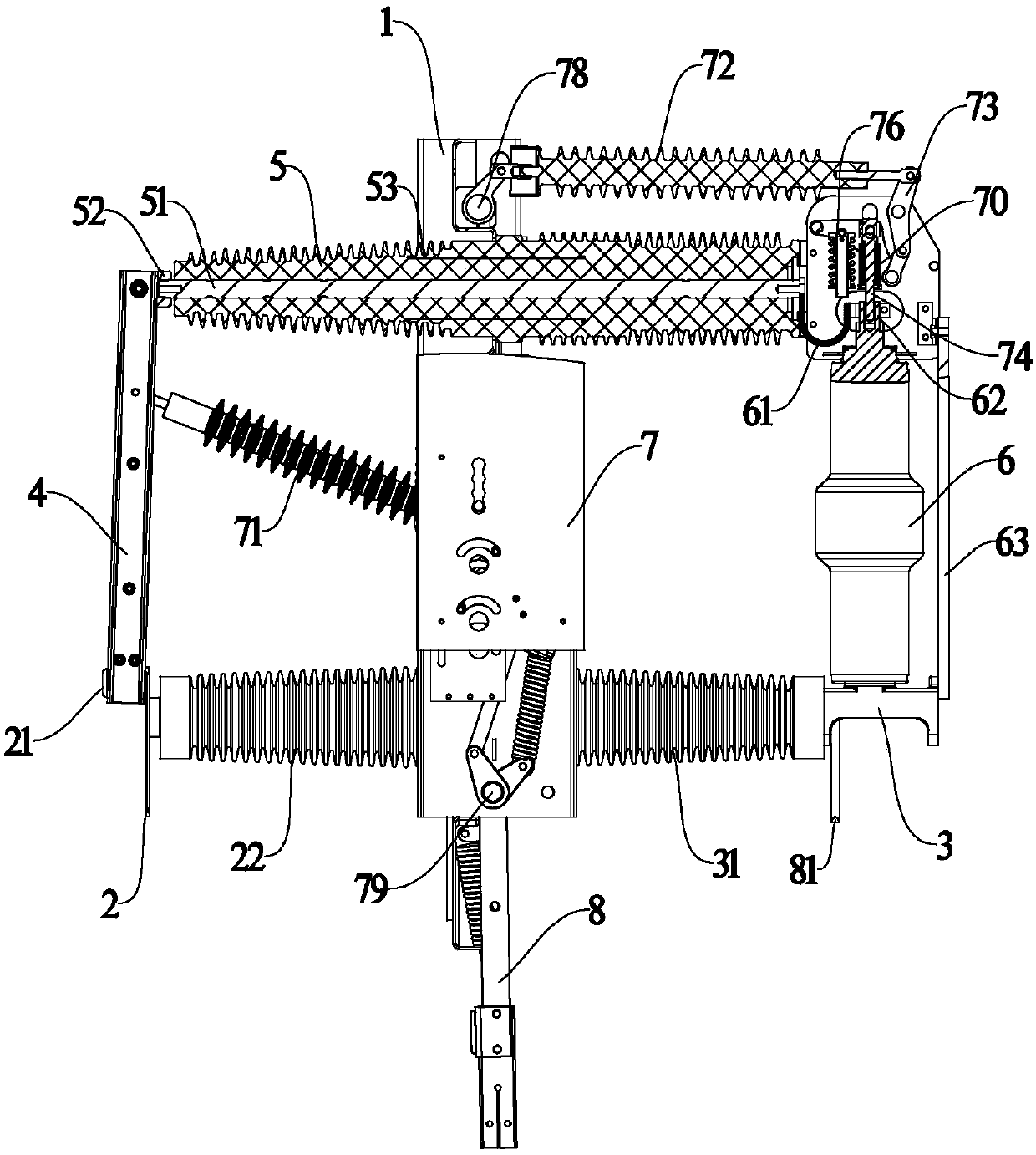

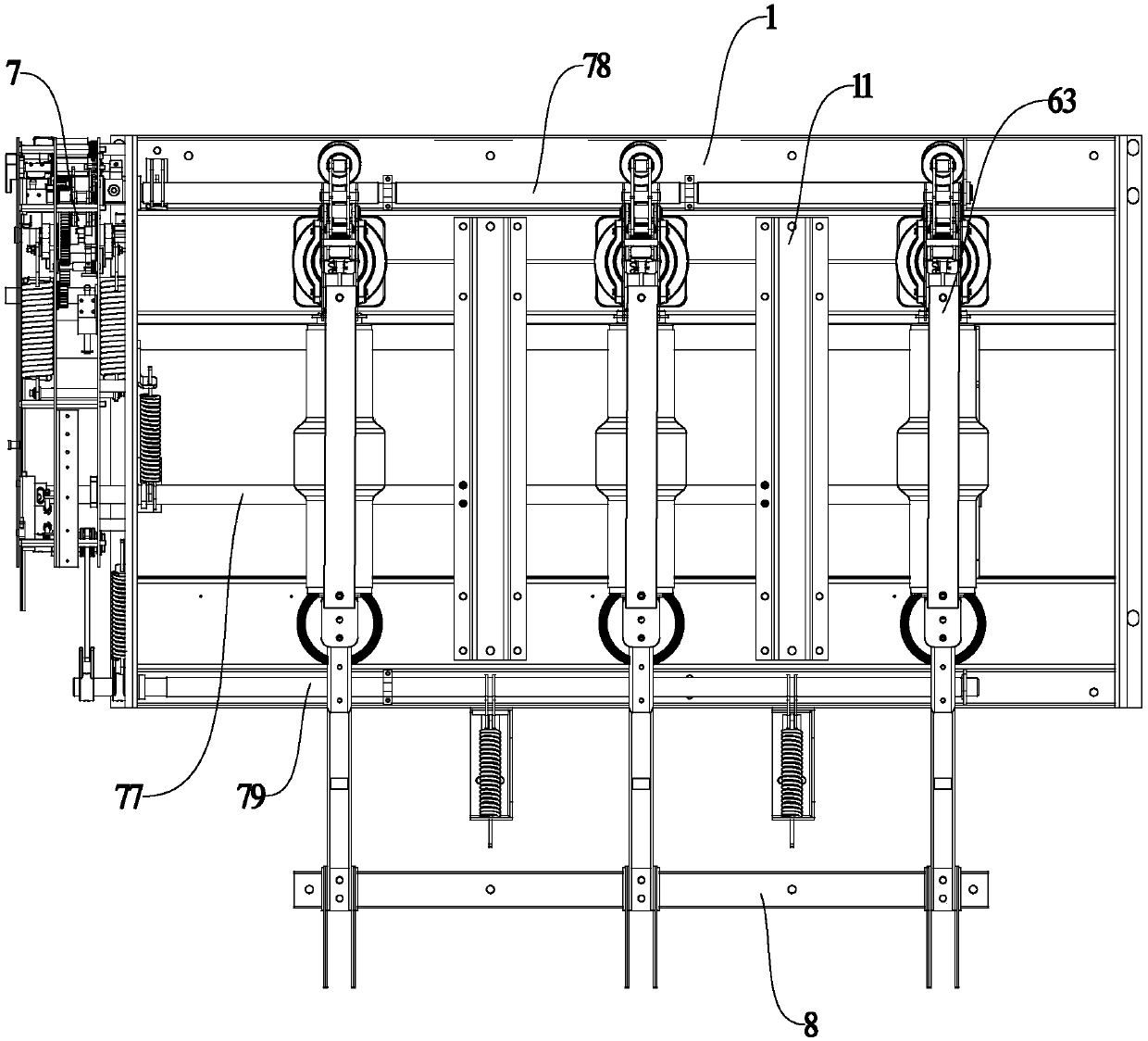

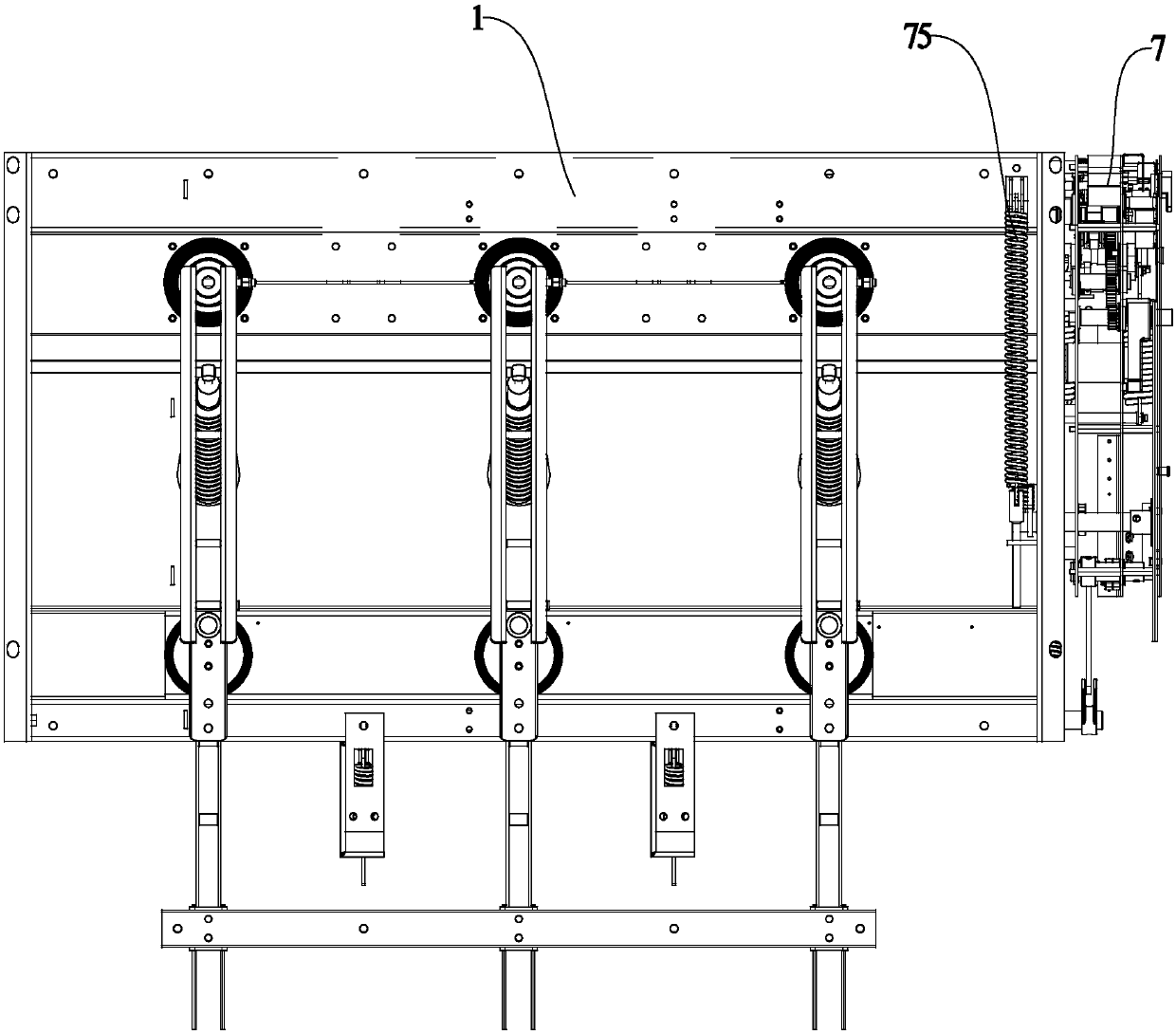

[0023] Such as Figure 1~3 As shown, a preferred embodiment of the present invention includes a base frame 1, and three groups of wiring boards 2 and conductive seats 3 are respectively insulated on both sides of the base frame 1. The wiring board 2 is electrically connected to the incoming cable, and the conductive base 3 is electrically connected to the outgoing cable.

[0024] The key point is that a contact knife 4, a wall-through pole 5 and a vacuum interrupter 6 are sequentially arranged between each group of wiring boards 2 and the conductive seat 3, and an operating mechanism 7 is arranged on the bottom frame 1. A first insulating rod 71 is set between the mechanism 7 and the contact knife 4, a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com