90-degree over-mode waveguide TE01-TM11 mode converter

A mode conversion and over-mode waveguide technology, applied to waveguide devices, electrical components, circuits, etc., can solve problems such as inconvenient docking and limited working bandwidth, and achieve the effects of simple structure, improved efficiency, and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

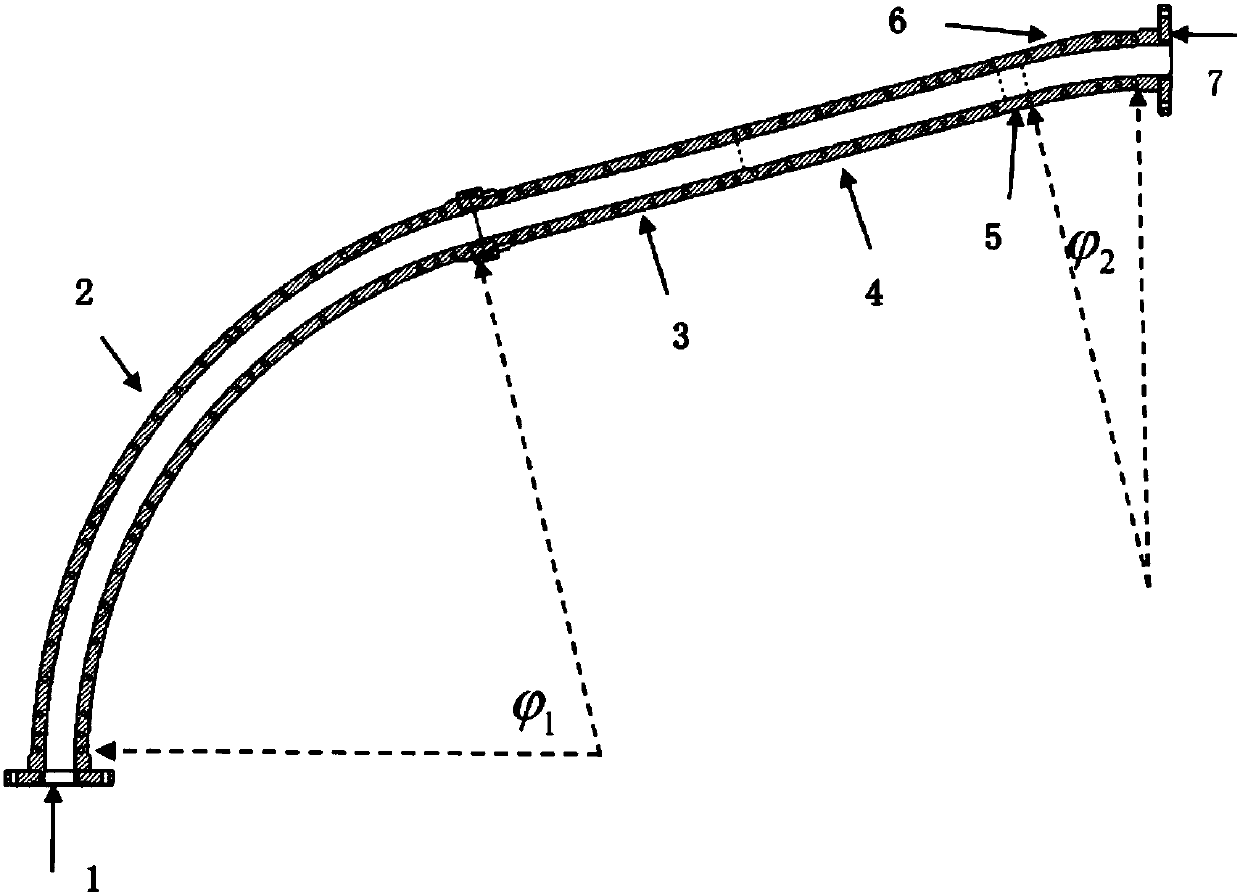

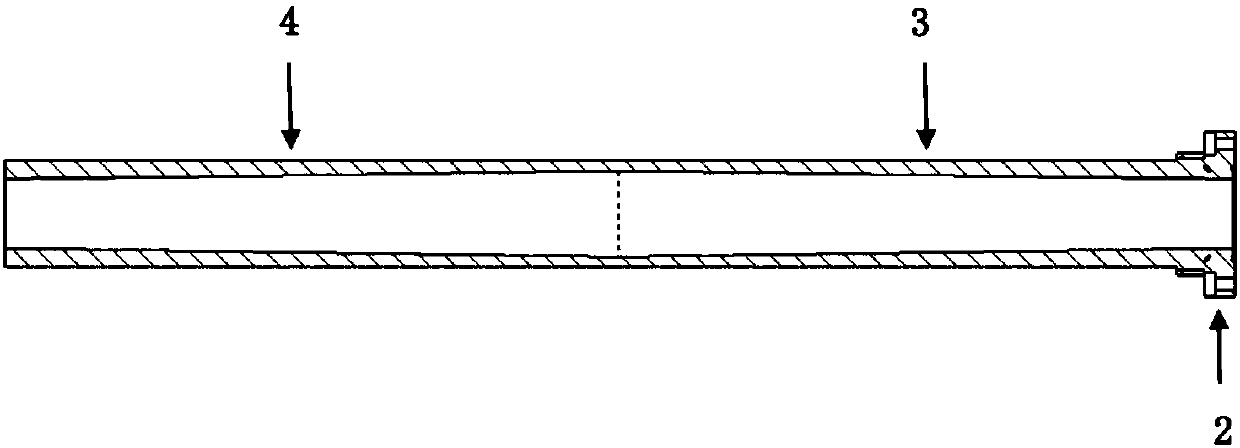

[0049] In the case where the length of the axial direction of the input end is short, that is, in the , The passing angle is TE 01 Convert all to TM 11 Pattern, then go through After reaching the phase reversal section, at this time TM 11 Part of the model has been converted to TE 01 , And TM 11 Mode phase lag TE 01 Mode 90 degrees. After the phase reversal section TM 11 Mode leading TE 01 Mode 90 degrees. In the uniform phase shift section, the modes do not couple. After the uniform phase shift section, the waveguide enters the second mode conversion section due to the bending of the waveguide. 01 Mode to TM 11 Mode conversion coupling. after The second mode of the angle reaches the output port after the second mode change section, at this time TE 01 Fully converted to TM 11 mode.

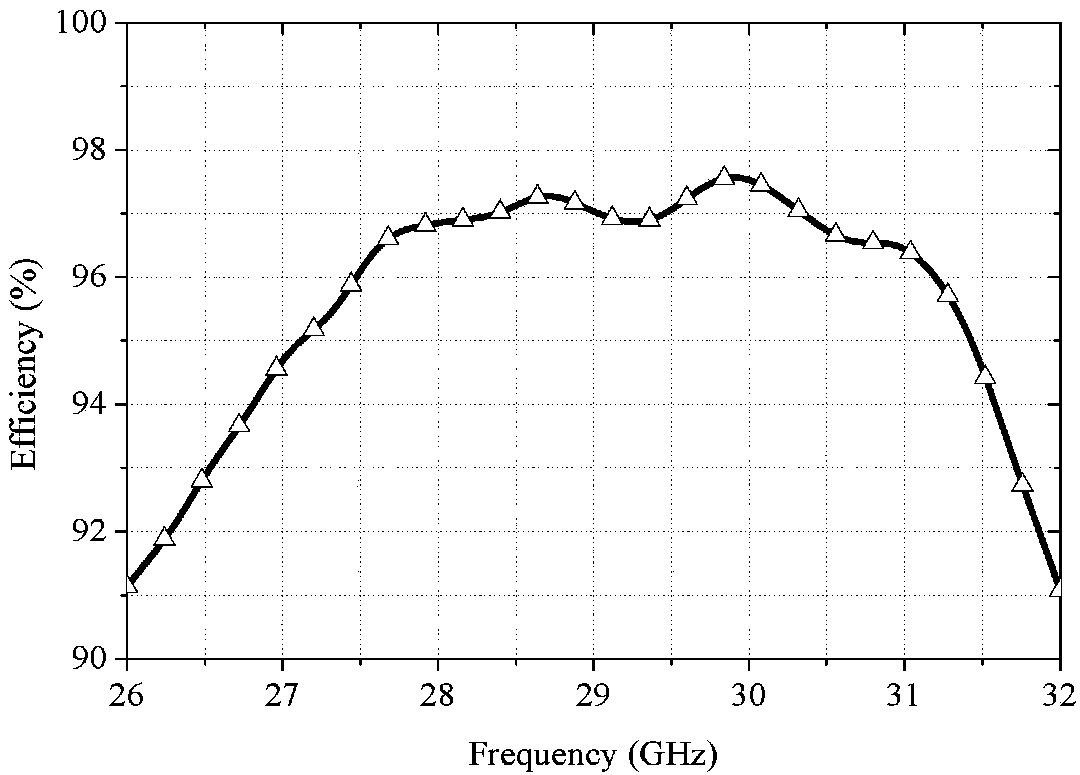

[0050] In this embodiment, the axial length of the input end is shorter, that is The input waveguide radius is 12.4mm, the turning radius R of the first mode conversion section and the second mo...

no. 2 example

[0054] In the case where the length of the axial direction of the input end is long, that is, in the In the case of the angle After the first mode change section, TE 01 Partially converted to TM 11 Mode, at this time TM 11 Mode phase lead TE 01 Mode 90 degrees. After the phase reversal section, TM 11 Mode phase lag TE 01 Mode 90 degrees. After the uniform phase shift section, the waveguide enters the second mode conversion section due to the bending of the waveguide, making the TM 11 Mode to TE 01 Mode conversion coupling. The passing angle in the second mode conversion section is After the bending section, the TM is excited 11 Mode fully converted to TE 01 mode. From To the output port, TE 01 To TM 11 Conversion, fully converted to TM at the output port 11 mode.

[0055] The structural parameters in this embodiment are as follows: the radius of the input circular waveguide is 12.6 mm. The turning radius R of the two-mode conversion section is 375mm, and the angle of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com