Pressure touch screen and mobile terminal having same

A technology of touch screen and pressure, which is applied to equipment with touch panel/sensor/detector, input/output process of data processing, telephone structure, etc., which can solve the problem of low response sensitivity of pressure touch screen and reduce production cost and other problems to achieve the effect of reducing production costs and solving low reaction sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

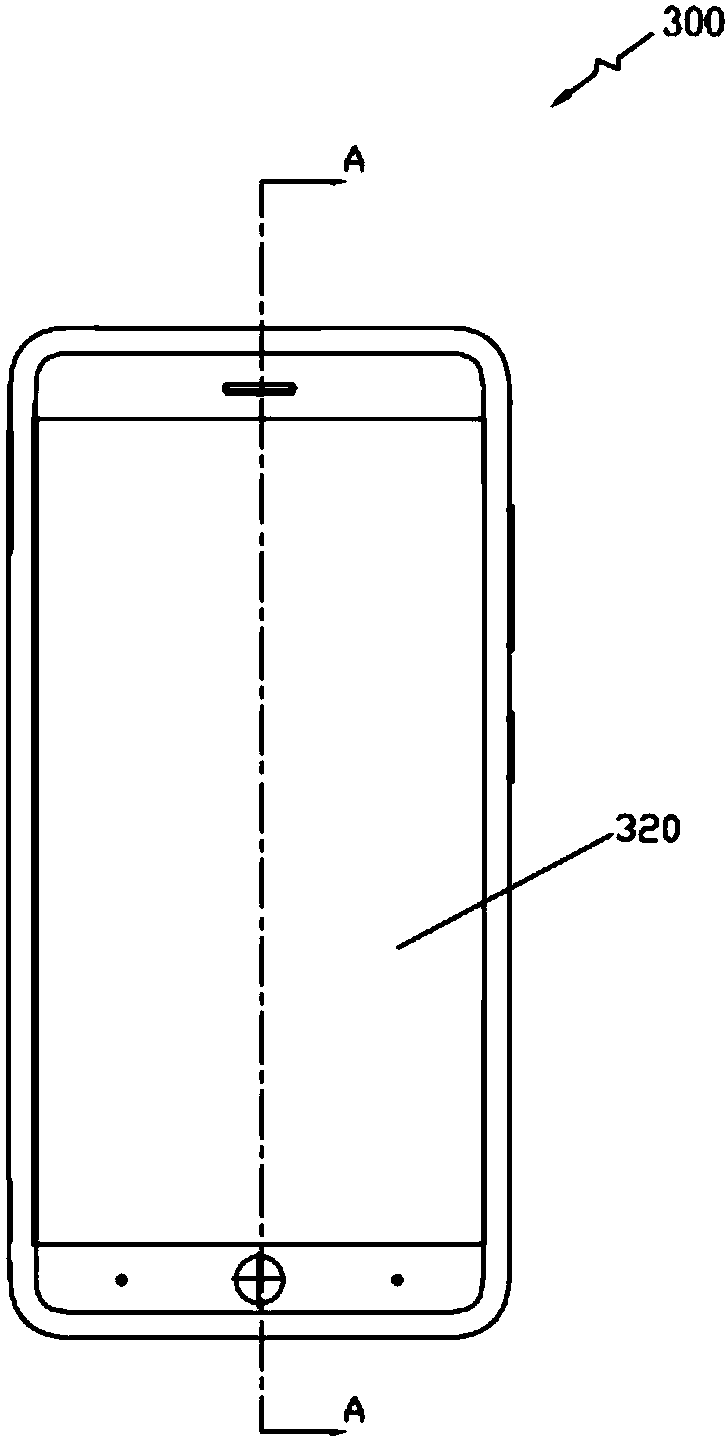

[0055] Such as image 3 and Figure 4 As shown, Embodiment 1 of the present invention proposes a pressure touch screen 300 , the pressure touch screen 300 includes a sealed cavity 310 , a screen main body 320 , a signal acquisition and processing unit 330 and a terminal middle frame 340 .

[0056] Wherein, the sealed cavity 310 is disposed inside the screen main body 310 . Specifically, such as Figure 4 to Figure 6As shown, the screen main body 320 is fastened to the terminal middle frame 340 by sealing foam 350 and glue (not shown), so that the sealed cavity 310 is formed between the terminal middle frame 340 and the inner side of the screen main body 320 . The sealing foam can be PU foam, or CR foam, or EPE foam, so as to ensure the sealing performance of the sealing cavity 310 through a foam structure with good sealing performance.

[0057] The screen main body 320 is mainly used to accept external pressure, and deform under the external force, so that the air pressure ...

Embodiment 2

[0061] Such as Figure 7 and Figure 8 As shown, Embodiment 1 of the present invention proposes a pressure touch screen 400 , which includes a sealed cavity 410 , a screen body 420 , a signal acquisition and processing unit 430 , a terminal middle frame 440 and a linear motor 460 .

[0062] Wherein, the sealed cavity 410 is disposed inside the screen main body 410 . Specifically, such as Figure 8 to Figure 10 As shown, the screen main body 420 is fastened on the terminal middle frame 440 by sealing foam 450 and glue (not shown), so that the sealed cavity 410 is formed between the terminal middle frame 440 and the inner side of the screen main body 420 . The sealing foam can be PU foam, or CR foam, or EPE foam, so as to ensure the sealing performance of the sealing cavity 410 through a foam structure with good sealing performance.

[0063] The screen main body 420 is mainly used for receiving external pressure, and deforms under the external force, so that the air pressure ...

Embodiment 3

[0068] Embodiment 3 of the present invention proposes a mobile terminal. The mobile terminal includes the pressure touch screen 300 in Embodiment 1. The pressure touch screen 300 includes a sealed cavity 310, a screen main body 320, a signal acquisition and processing unit 330, and a terminal Box 340 .

[0069] Wherein, the sealed cavity 310 is disposed inside the screen main body 310 . Specifically, such as Figure 4 to Figure 6 As shown, the screen main body 320 is fastened to the terminal middle frame 340 by sealing foam 350 and glue (not shown), so that the sealed cavity 310 is formed between the terminal middle frame 340 and the inner side of the screen main body 320 . The sealing foam can be PU foam, or CR foam, or EPE foam, so as to ensure the sealing performance of the sealing cavity 310 through a foam structure with good sealing performance.

[0070] The screen main body 320 is mainly used to accept external pressure, and deform under the external force, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com