Heat-insulating foam paper and preparation method thereof

A coating layer and base layer technology, applied in the field of thermal insulation foam paper and its preparation, can solve the problems of high melting point of HDPE, high rate of poor adhesion, easy to produce orange peel, etc., and achieve good thermal insulation performance and product quality. Good, fine-feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

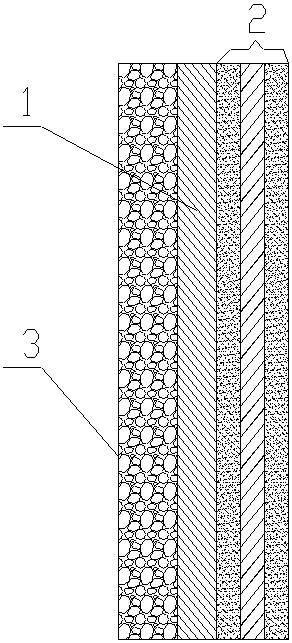

[0019] A heat-insulating foamed paper, which includes a middle paper base layer 1, an inner coating layer 2 and an outer coating layer, the inner coating layer is a three-layer co-extrusion coating layer of LDPE / HDPE / LDPE, and the three layers Layers of co-extruded materials are in the order of being close to the paper base layer outward, and the mass dosage ratio is 1:3:1;

[0020] The paper base layer in the middle is cup base paper, and the cup base paper is used for humidification treatment, so that the humidity is controlled at 10% by grammage.

[0021] The raw material of the outer coating layer is a plastic blend of 70% LDPE and 30% POE. The melt index (dg / min) of the LDPE plastic is 6-7.5.

[0022] A method for preparing heat-insulating foam paper. Raw materials are prepared according to the above proportions, and placed in the feeding barrels of a double-sided laminating machine, and the two sides of the paper base are coated at the same time. The temperature of the ...

Embodiment 2

[0027] A method for preparing heat-insulating foamed paper, the inner coating layer is a three-layer co-extrusion coating layer of LDPE / HDPE / LDPE, and the mass of the three-layer co-extrusion material is in the order of being close to the paper base layer and outward. The dosage ratio is 1:4:4;

[0028] The paper base layer in the middle is base paper for noodle bowls, and the base paper for noodle bowls is used for humidification treatment, so that its humidity is controlled at 9% by weight.

[0029] The raw material of the outer coating layer is a plastic blend of 70% LDPE and 30% POE. The melt index (dg / min) of the LDPE plastic is 6-7.5.

[0030] A method for preparing heat-insulating foam paper. Raw materials are prepared according to the above proportions, and placed in the feeding barrels of a double-sided laminating machine, and the two sides of the paper base are coated at the same time. The temperature of the die head is 300-320 ℃, the speed is 50-180m / min, and the ...

Embodiment 3

[0035] A method for preparing heat-insulating foam paper, which is different from Reference 2 in that the raw material of the outer coating layer is a plastic blend of 65% LDPE and 35% POE. The heat-insulating paper bowl of making, the softness of the foam layer on the surface is better than embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com