Guide bearing supporting structure of vertical hydroelectric unit

A technology for generating sets and supporting structures, which is applied in hydroelectric power generation, engine components, machines/engines, etc. It can solve the problems of increasing construction and maintenance costs of power stations, complex guide bearing supporting structures, and unreasonable supporting structure design. Easy maintenance, easy disassembly and assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

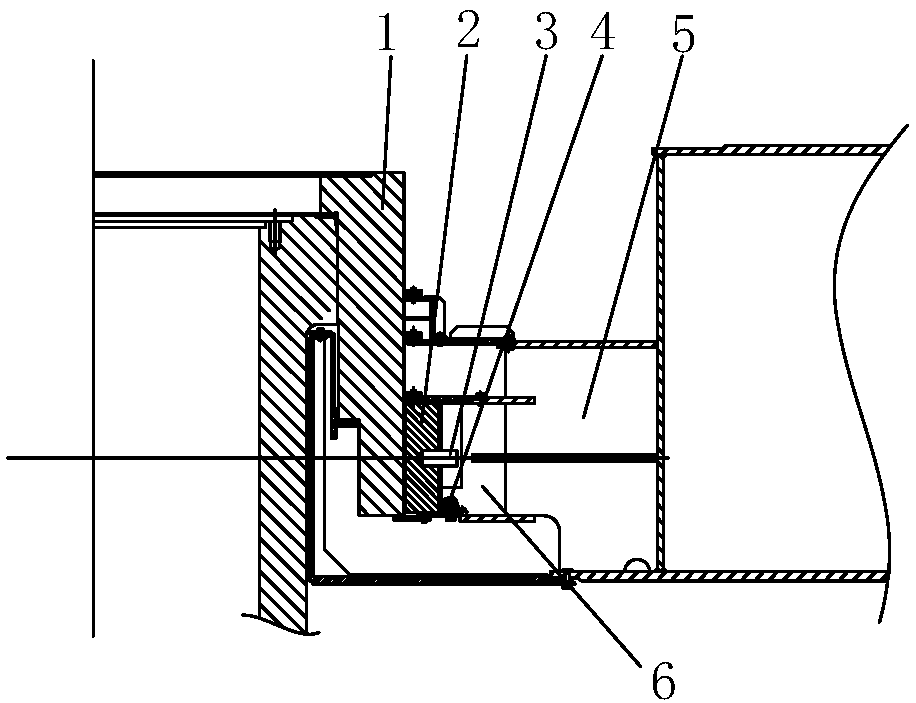

[0028] Now in conjunction with accompanying drawing, the present invention will be further described:

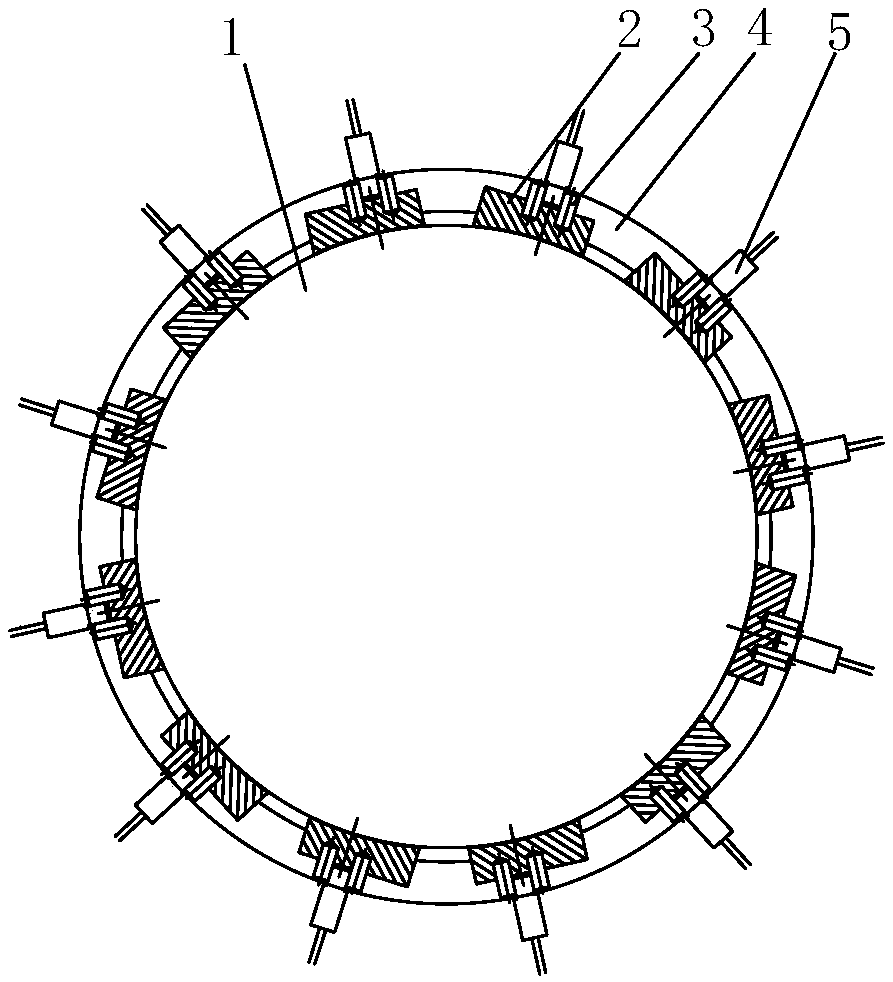

[0029] As shown in the figure, a guide bearing support structure of a vertical hydroelectric generator set is characterized in that it includes:

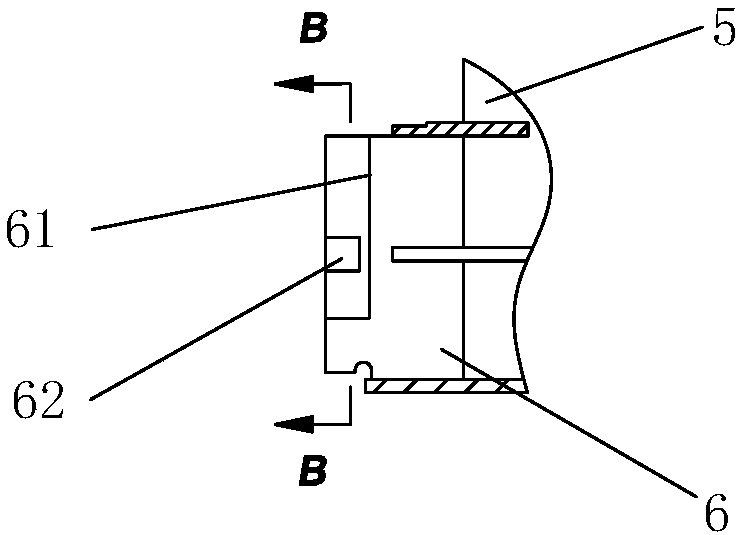

[0030] The frame body 5 is fixed with the foundation concrete;

[0031] Guide bearing pad 2, multi-piece, which is provided with an arc surface, the arc surface of the guide bearing pad 2 is installed close to the guide bearing, the multiple pieces of guide bearing pad 2 are evenly arranged relative to the center of the guide bearing, and the guide bearing pad 2 is provided with two blind holes , the guide bearing is used to install the rotating shaft of the vertical hydro-generator set;

[0032] Cylindrical pins 3, two cylindrical pins 3 are configured for each guide bush 2, one end of the two cylindrical pins 3 is inserted into the two blind holes of the guide bush 2, and the other end protrudes from the blind hole;

[0033] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com