Aircraft pressure detection equipment and application method thereof

A technology for detecting equipment and pressure, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of large pressure error, easy aging and error of high-pressure resistant rubber tubes, etc., to reduce measurement errors and pressure loss, good resistance Pressure resistance to high and low temperature performance, ensuring the effect of bonding and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

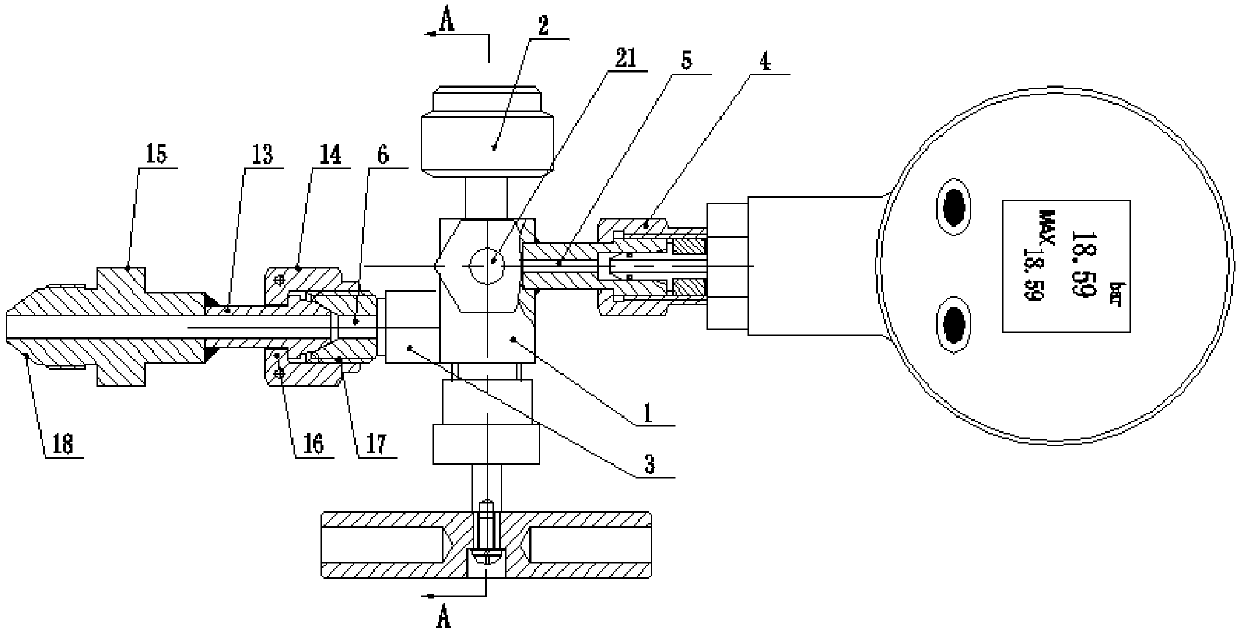

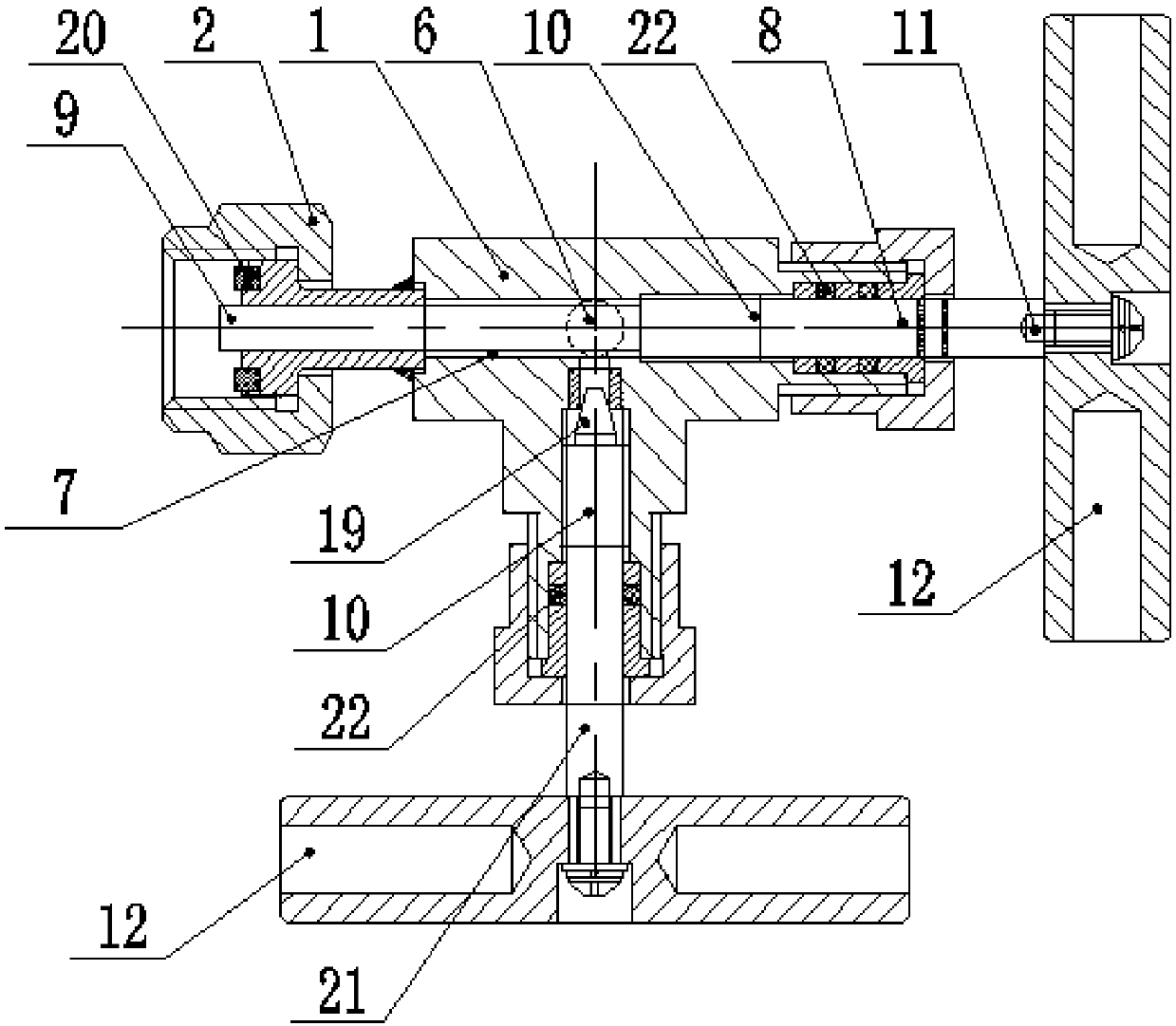

[0049] An aircraft pressure detection device, characterized in that it includes a valve body 1, a product interface 2, an inflation and deflation interface 3, and a measurement interface 4, and the valve body 1 is provided with a measurement channel 5, an inflation and deflation channel 6, and a product connection channel 7. The inflation and deflation passage 6 and the product connection passage 7 are connected to the measurement passage 5 respectively, the inflation and deflation passage 6 is provided with a stop valve 21 , and the product connection passage 7 is provided with a sealing ejector rod 8 .

[0050]Also includes an adapter 13, the adapter 13 includes a connecting pipe head 14 and an air source connecting head 15, the connecting pipe head 14 is provided with a sealing chuck 16 and an adapter thread 17, and the air source connecting head 15 is provided with a sealing surface 18. The adapter thread 17 is connected to the inflation and deflation interface 3, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com