Connecting device for inlet pipe of silking machine and middle guide tube

A technology of connecting device and laying machine, applied in the direction of guiding/positioning/aligning device, etc., can solve the problems of hindering the advancement of rolling pieces, affecting the production quality and progress, stacking steel, etc., so as to reduce the downtime and improve the service life. , Eliminate the effect of collision-prone section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

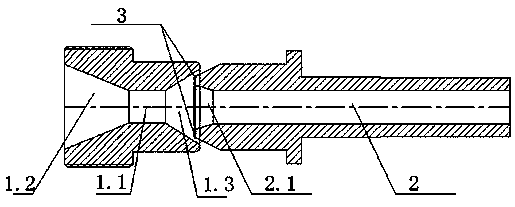

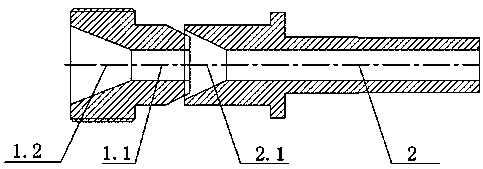

[0018] Such as figure 1 As shown, the rolling direction is from the inlet of the laying machine to the middle pipe. Before the improvement, the two ends of the inlet of the laying machine are a straight pipe 1.1 respectively connected to a large diameter reducing pipe 1.2 and a small diameter reducing pipe 1.3, and two diameter reducing pipes All are that the small-section end is connected with the straight pipe, and the mouth 2.1 of the middle conduit 2 is a variable-diameter mouth. The large cross-section end of the small variable-diameter tube of the inlet pipe of the laying machine is connected with the large-section end of the variable-diameter port of the middle conduit, and the connecting surface area of the middle conduit and the inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com