Automatic boxing flattening machine

An automatic boxing and leveling machine technology, applied in packaging and other directions, can solve the problems of plastic bag damage, uneven distribution of products, squeezed cartons, etc., and achieve the effect of improved leveling efficiency, good leveling effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

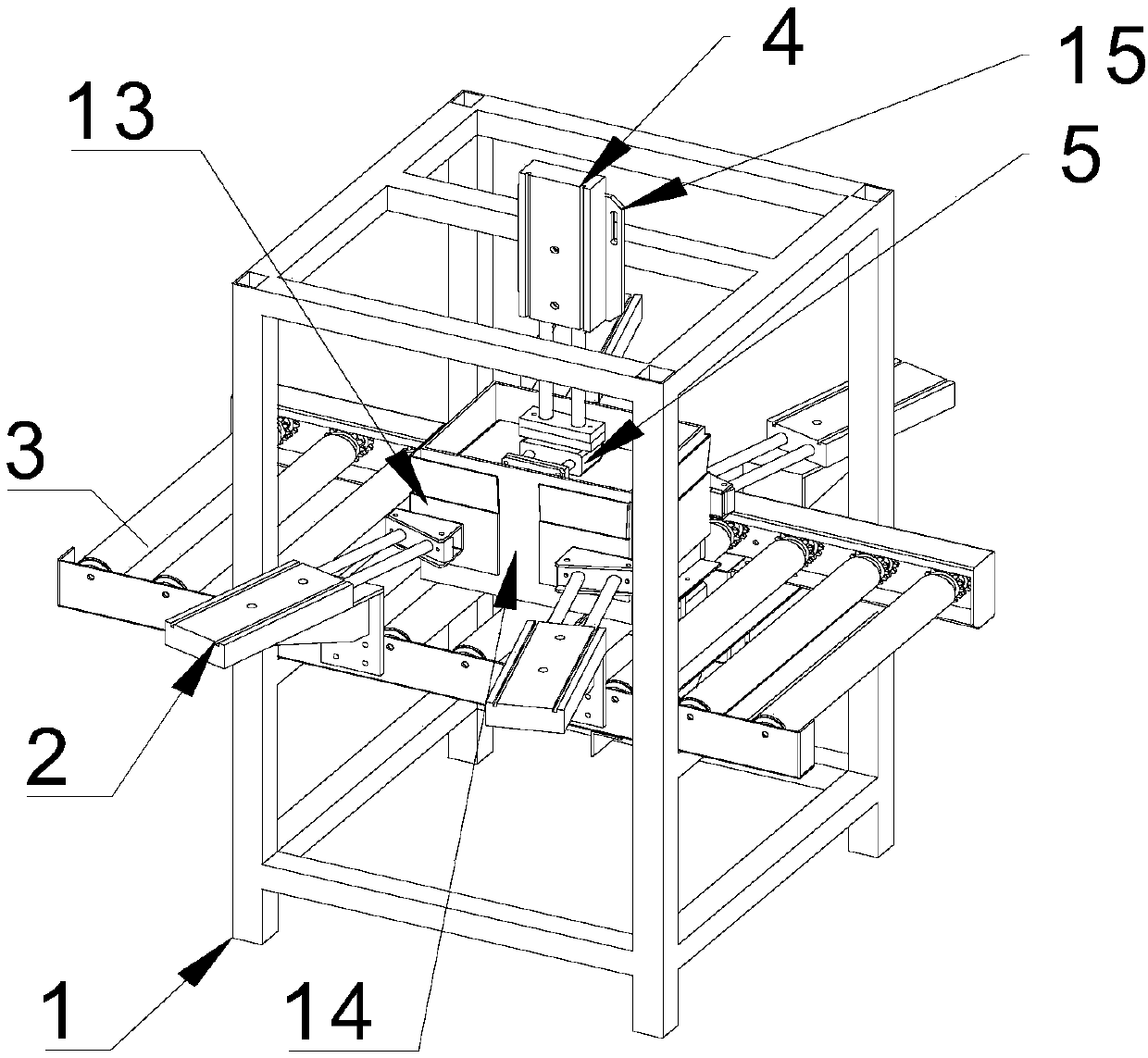

Image

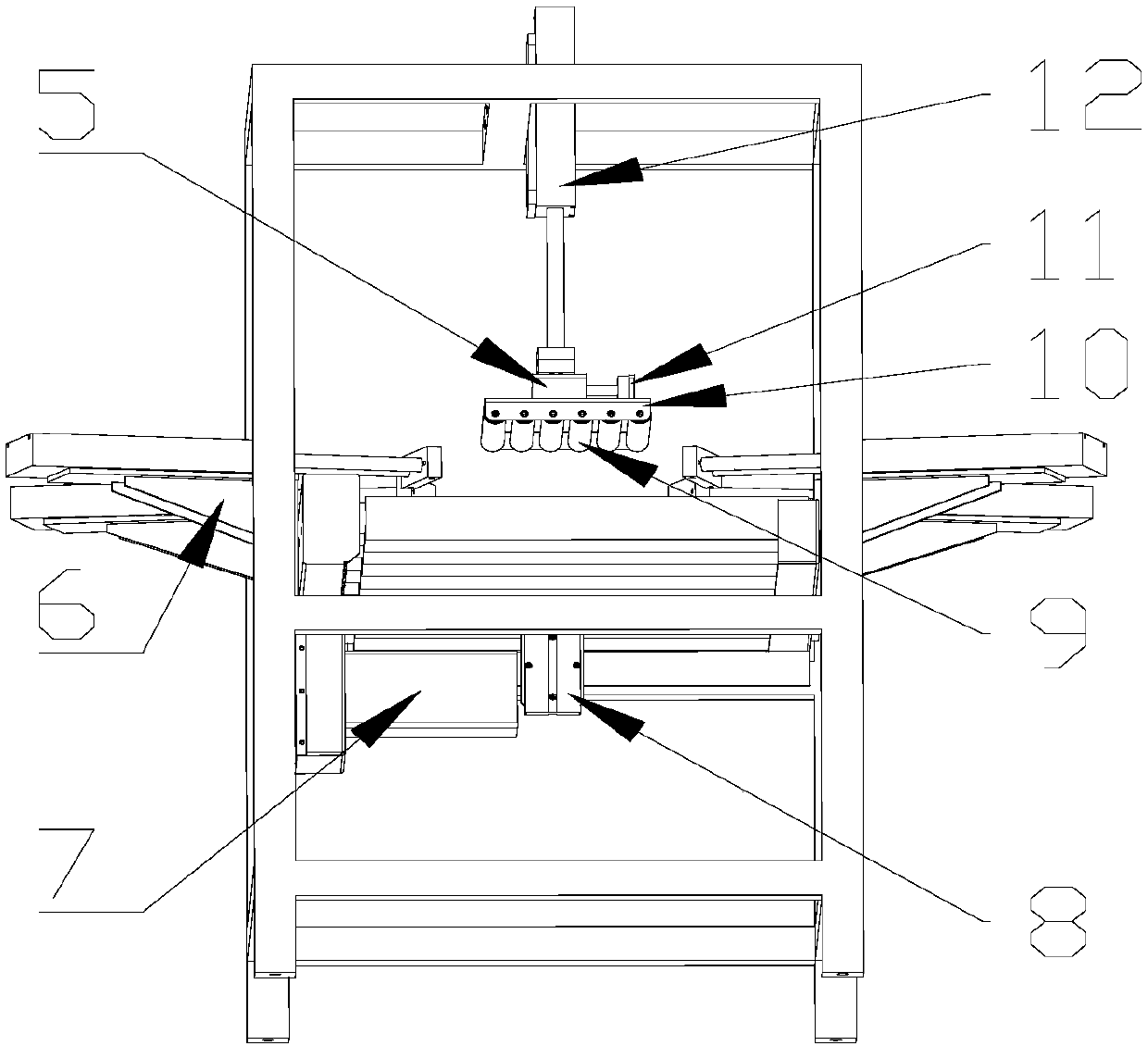

Examples

specific Embodiment 2

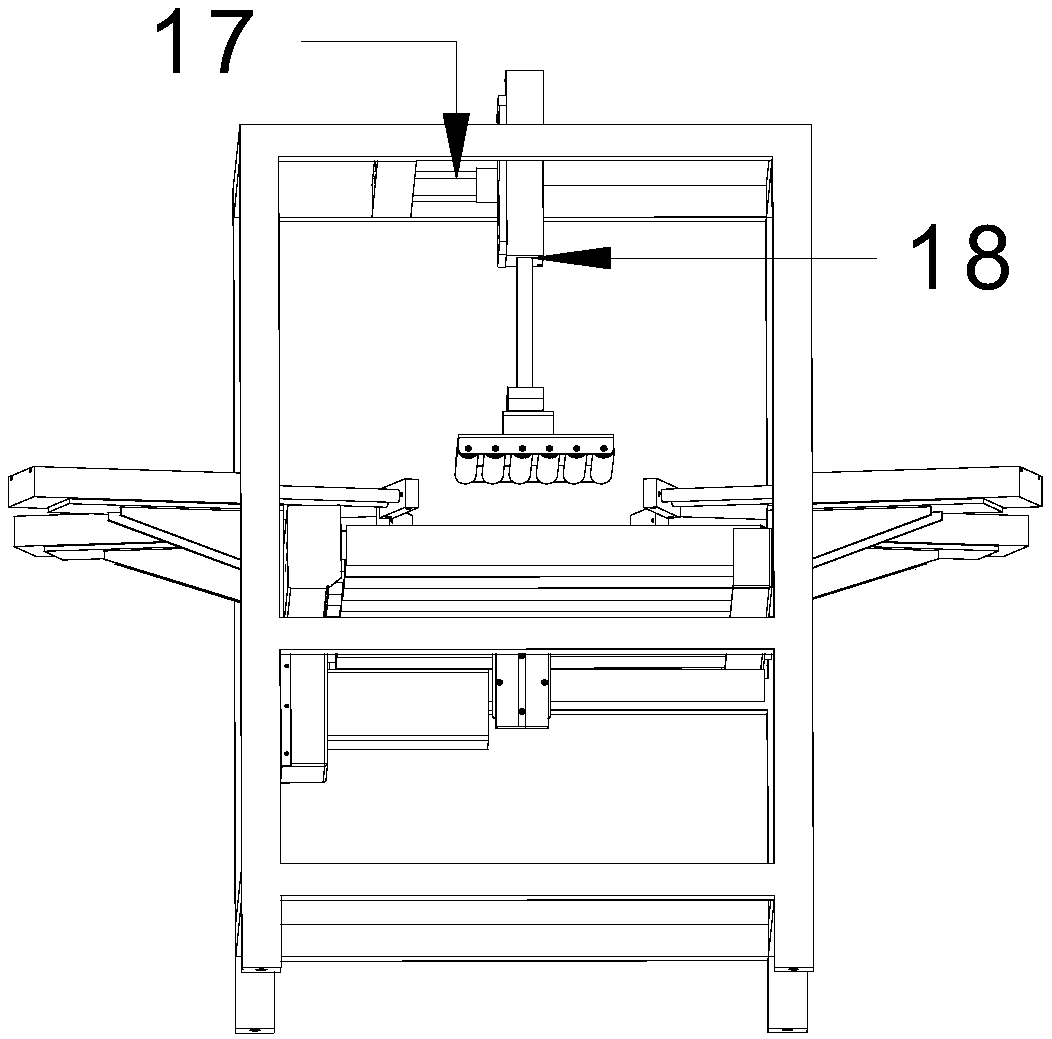

[0023] as follows image 3 Shown is another specific embodiment 2 of the present invention, a kind of automatic box-packing and paving machine, including frame, conveying assembly, folder box assembly, flattening assembly, telescopic cylinder and paving device, said flattening assembly Including the pressure box cylinder 18 and the pressure box cylinder fixing plate, the packing box reaches the fixed position, the box clamping cylinder clamps the packing box, the pressure box cylinder presses down, and the telescopic cylinder stretches back and forth after the pressure box cylinder moves in place , the telescopic cylinder 17 drives the paving device to reciprocate. The telescopic cylinder 17 is arranged on the top of the frame, the front end of the telescopic cylinder 17 fixes the press box cylinder fixed plate, the press box cylinder is arranged on the fixed plate, and the front end of the press box cylinder 18 is provided with a paving device.

[0024] The paving device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com