Protection equipment used for construction site waste treatment station

A technology for protecting equipment and treatment stations, applied in applications, household appliances, garbage conveying, etc., can solve the problems of four-column garbage compressors without any protective devices, falling over, affecting life safety, etc., to facilitate safety management and reduce accident rates. , the effect of protecting life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

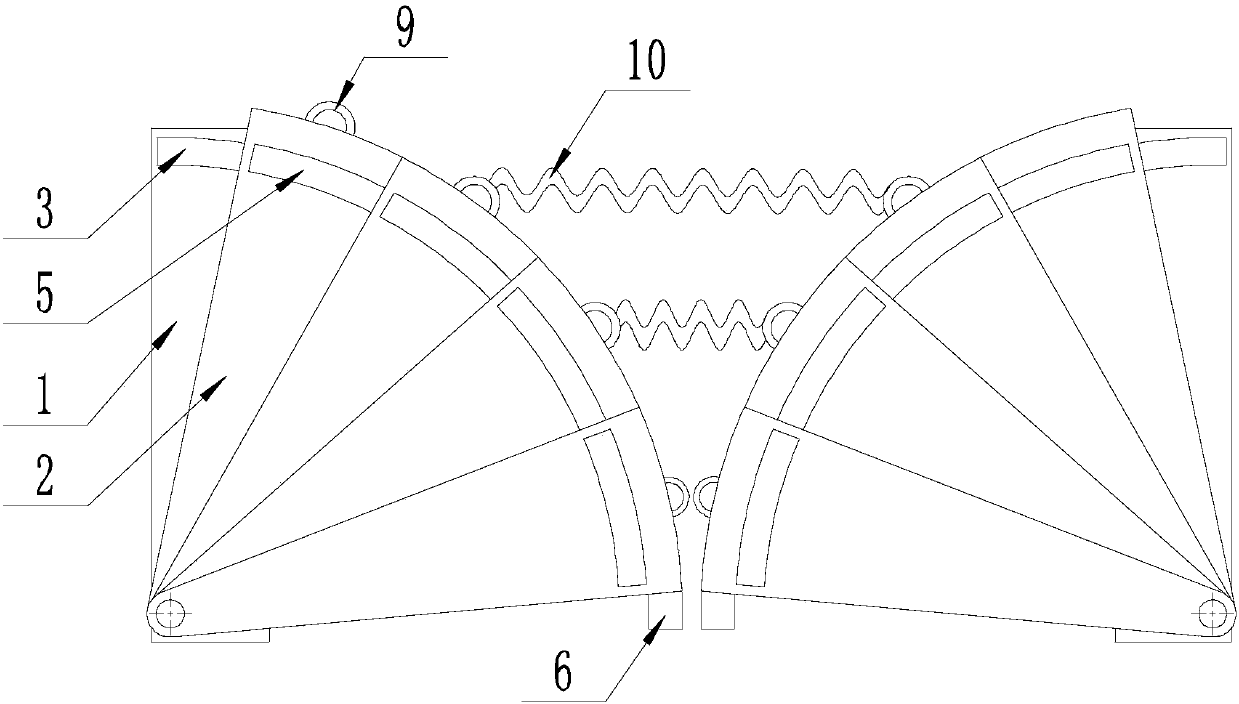

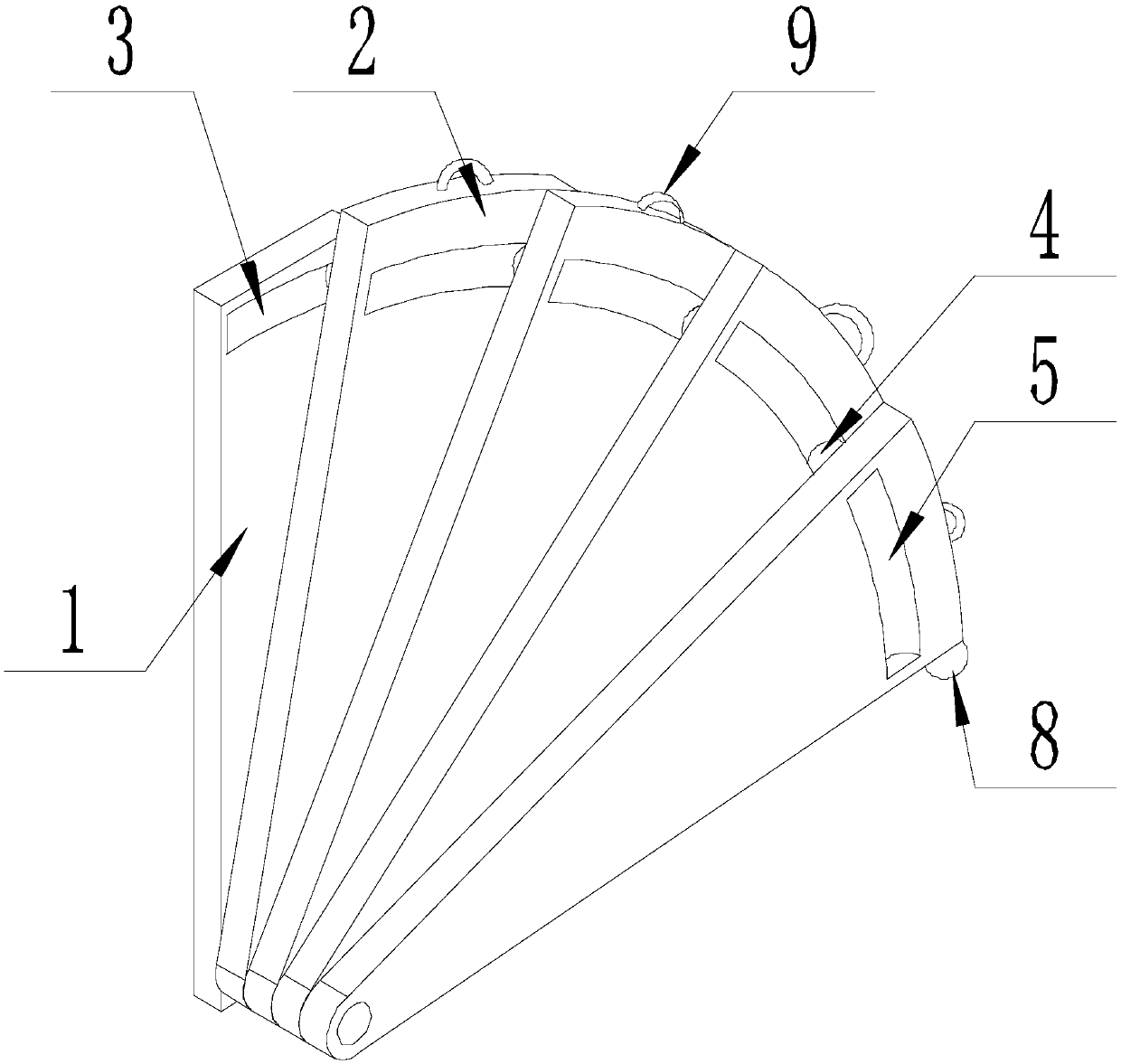

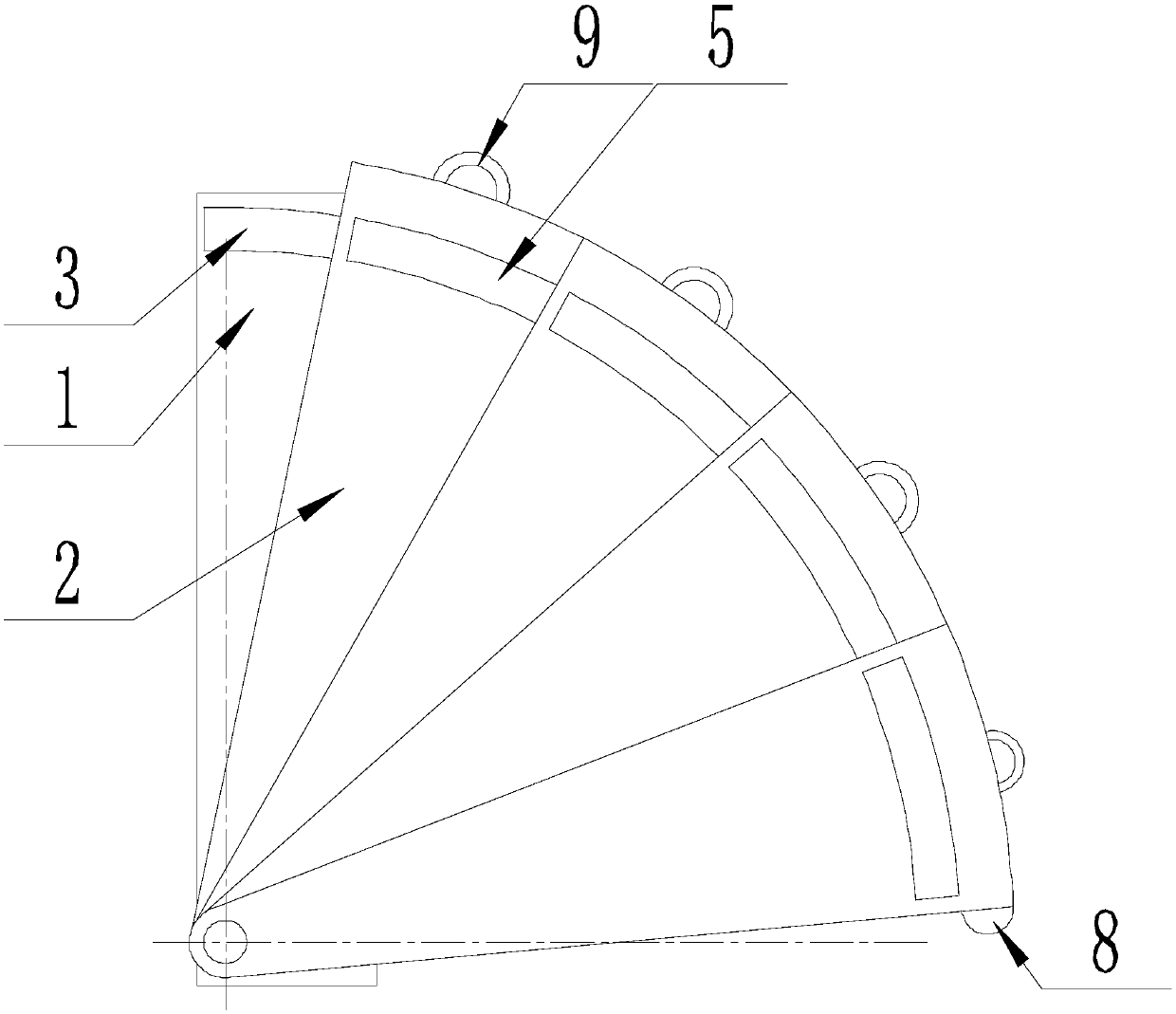

[0043] Such as Figure 1-Figure 10 As shown, the present invention is used for the protection equipment of the useless objects processing station on the construction site, including the fixed plate 1 and the rotating assembly connected in sequence, and the rotating assembly includes several overlapping moving plates 2, one end of the fixed plate 1 and the moving plate One end of the plate 2 is hinged to each other, and the fixed plate 1 and the moving plate 2 are both perpendicular to the hinge axis. A guide groove 3 is provided on the surface of the fixed plate 1 close to the moving plate 2, and on the moving plate 2 close to the fixed plate 1 Guide blocks 4 are provided on the board surfaces of the moving plate 2, and chute 5 is provided on the board surface of the moving plate 2 away from the fixed plate 1. In the rotating assembly, among the two adjacent moving plates 2, the moving plate far away from the fixed The guide block 4 of the plate 2 cooperates with the chute 5 o...

Embodiment 2

[0047] The present invention is based on embodiment 1, and the present invention is further described.

[0048] Such as Figure 1-Figure 10 As shown, the present invention is used for the protection equipment of the useless object processing station on the construction site, the opening dimensions of the guide groove 3 and the chute 5 are all smaller than the bottom size of the groove, and the cross-sectional dimensions of the guide groove 3 and the chute 5 are the same as those of the guide block 4 The cross-sectional dimensions are the same.

[0049] The cross-sections of the guide groove 3 and the chute 5 are all arc-shaped, the guide block 4 is spherical, and the diameters in the cross-section of the guide groove 3 and the chute 5 are consistent with the spherical diameter of the guide block 4 .

[0050] The cross-sections of the guide block 4 and the slot matched with it are both arranged in an arc shape, which is beneficial to the stability of the rotating movable plate...

Embodiment 3

[0052] The present invention is based on embodiment 1, and the present invention is further described.

[0053] Such as Figure 1-Figure 10 As shown, the present invention is used for the protection equipment of the useless object processing station on the construction site. A fixed seat 6 is provided on one side of the fixed plate 1, and a matching groove 7 is provided on the upper surface of the fixed seat 6. When rotating A matching block 8 is provided on the end of the moving plate 2 farthest from the fixed plate 1 in the assembly away from the hinge axis, and the moving plate 2 is rotated in turn to make the matching block 8 be inserted into the matching groove 7 .

[0054] By arranging the matching block 8 and the matching groove 7, the stability of the unfolded rotating assembly is increased to prevent the rotating assembly from being accidentally touched, causing the rotating assembly to be folded and lose its protective function.

[0055] Further, the matching block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com