A kind of 590mpa grade high-strength low-alloy hot-rolled pickled steel strip and its production method

A high-strength, low-alloy, hot-rolled pickling technology, which is applied to 590MPa-grade high-strength low-alloy hot-rolled and pickled strip steel and its production field, and can solve the problems of reduced hole enlarging and flanging performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

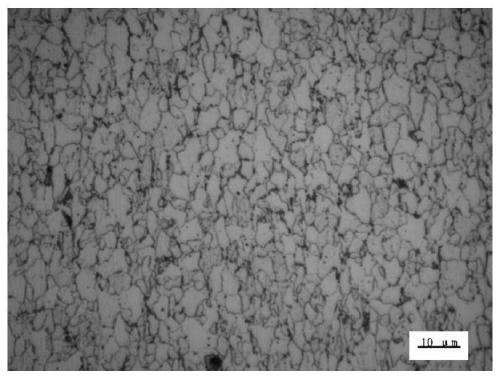

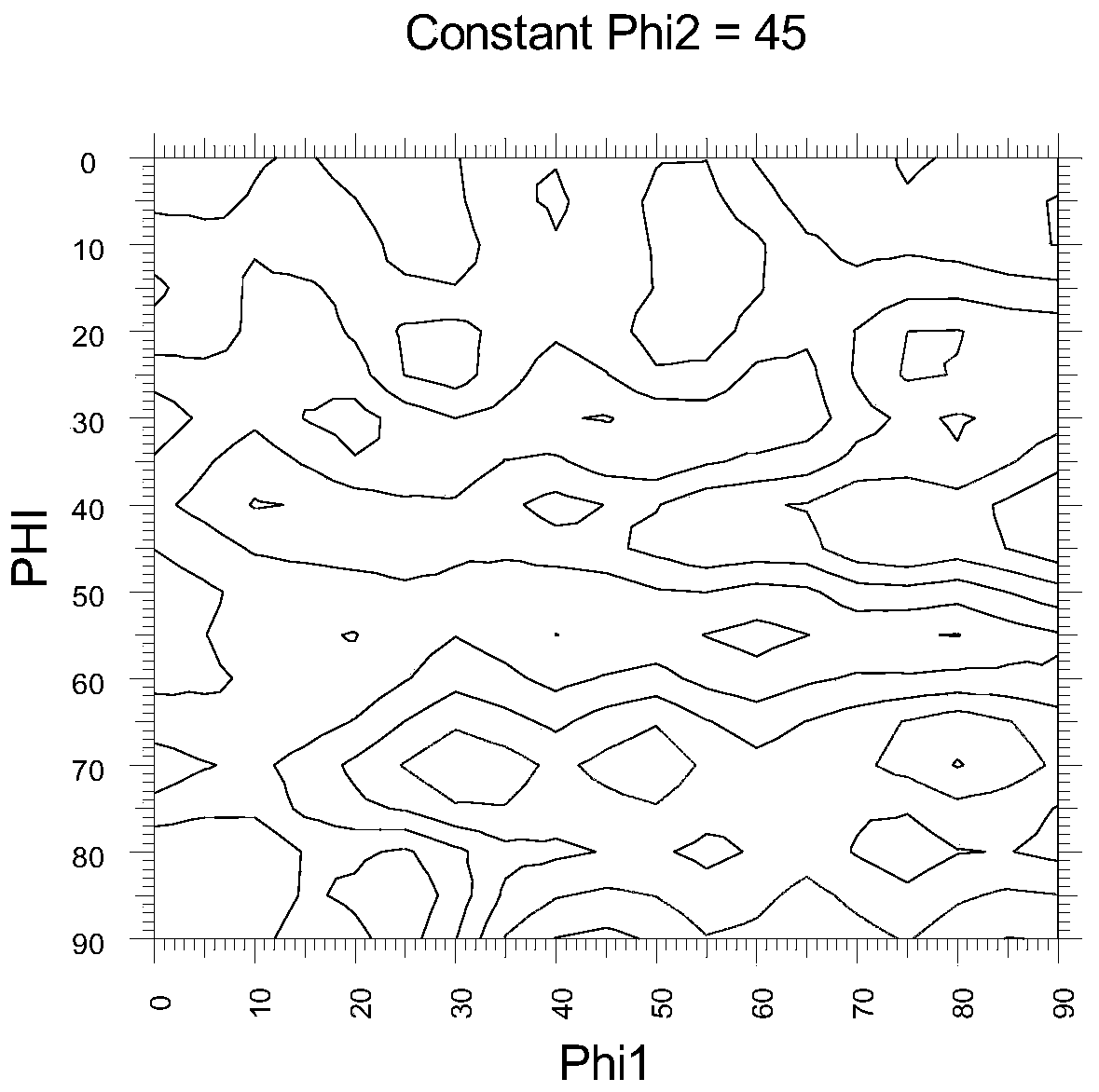

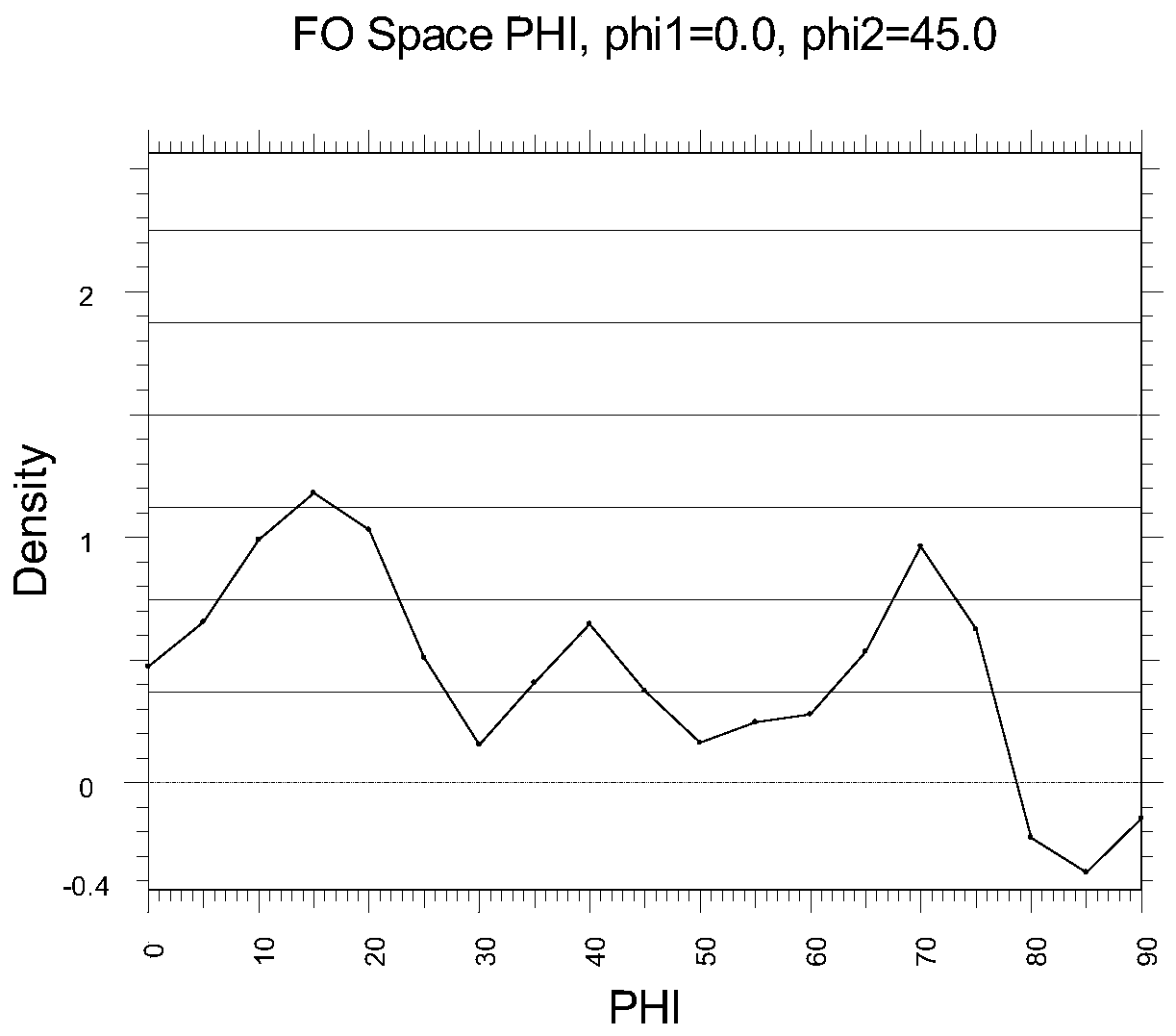

[0035] This patent mainly controls the formation of ferrite-pearlite structure with appropriate volume fraction ratio and high tensile strength, hole expansion and flanging performance of appropriate texture by adopting appropriate C and Mn element content and hot rolling and cooling process system Excellent high formability low alloy hot rolled pickled strip.

[0036] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0037] The invention discloses a 590MPa-level high-strength low-alloy hot-rolled pickled steel strip, in particular a ferrite-pearlite high-strength low-alloy hot-rolled pickled steel strip with excellent 590MPa-level hole expansion and flanging performance. The chemical composition is calculated by weight percentage: C: 0.05-0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com