Low-temperature ultrahigh magnetic induction oriented silicon steel with B800 greater than or equal to 1.962T and production method

An oriented silicon steel, ultra-high magnetic technology, applied in coating, metal material coating process, solid-state diffusion coating, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below:

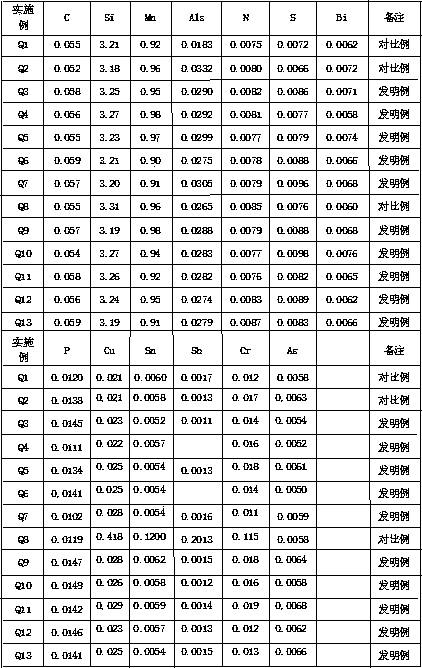

[0042] Table 1 is the value list of each embodiment of the present invention and comparative examples;

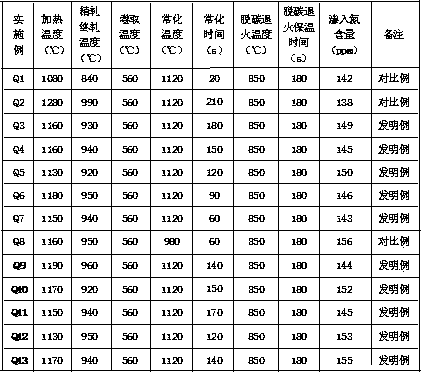

[0043] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

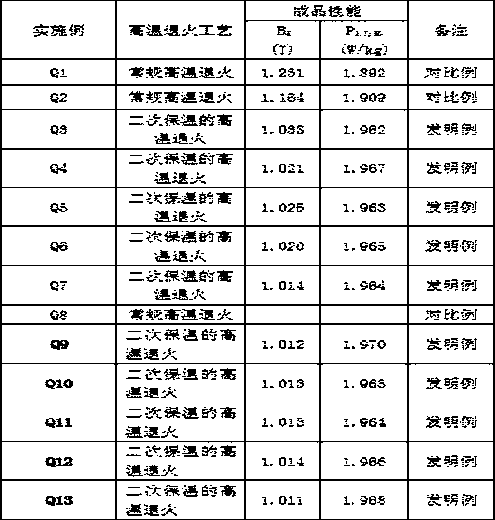

[0044] Table 3 is a list of the performance tests of the various embodiments of the present invention and comparative examples.

[0045] Each embodiment of the present invention is produced according to the following steps:

[0046] 1) Conventional smelting and continuous casting into billets;

[0047] 2) Heating the billet, the heating temperature is controlled at 1100~1200℃;

[0048] 3) Carry out hot rolling, and control the final rolling temperature at 850°C to 1000°C;

[0049] 4) For coiling, the coiling temperature does not exceed 600°C;

[0050] 5) Carry out normalization, the normalization temperature is 1000 ℃ ~ 1150 ℃, and keep warm at this temperature for 30 ~ 180s;

[0051] 6) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com