Battery module centralized storage and charging-discharging box system capable of ensuring fire fighting safety

A battery module and centralized technology, which is applied to battery pack components, secondary batteries, secondary battery repair/maintenance, etc., can solve problems such as inability to completely extinguish fires, threaten the safety of surrounding warehouses, and achieve diversified composition forms , Easy to install, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

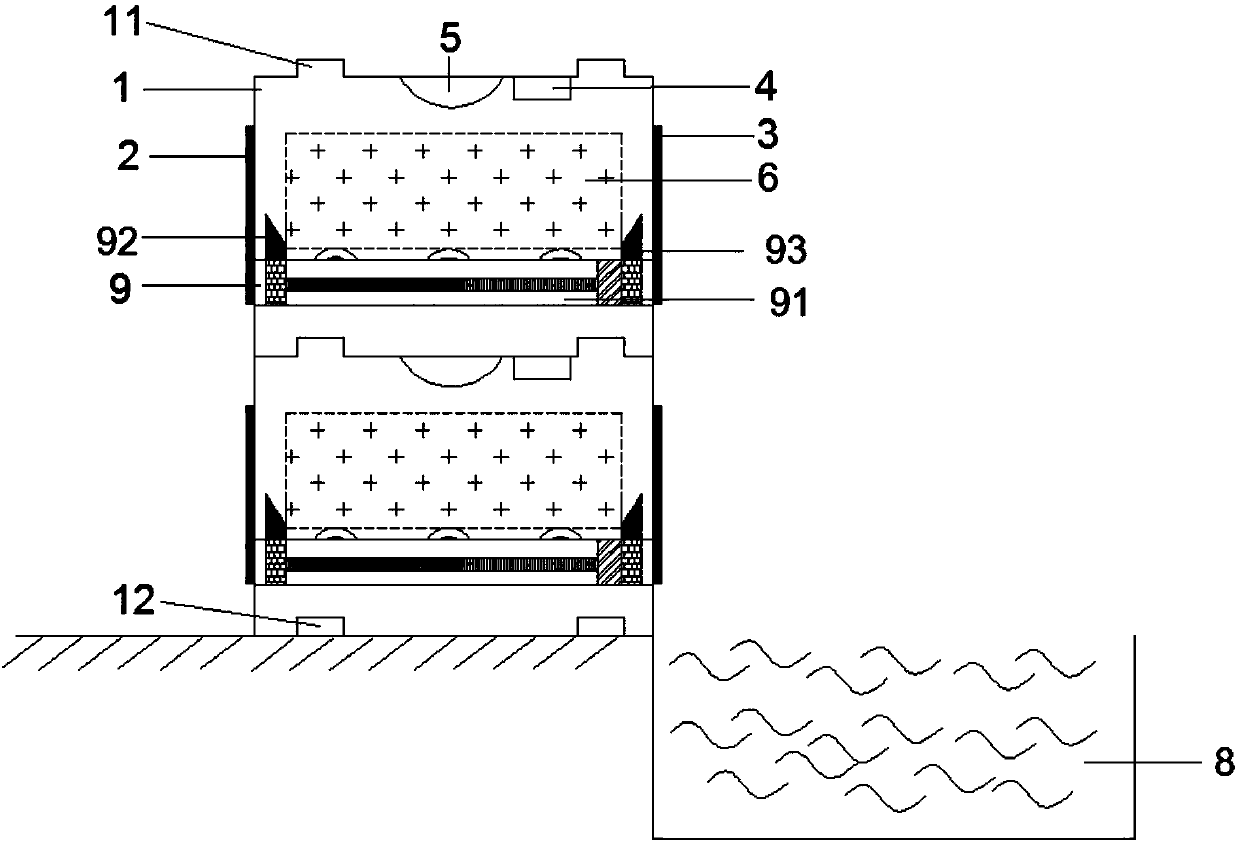

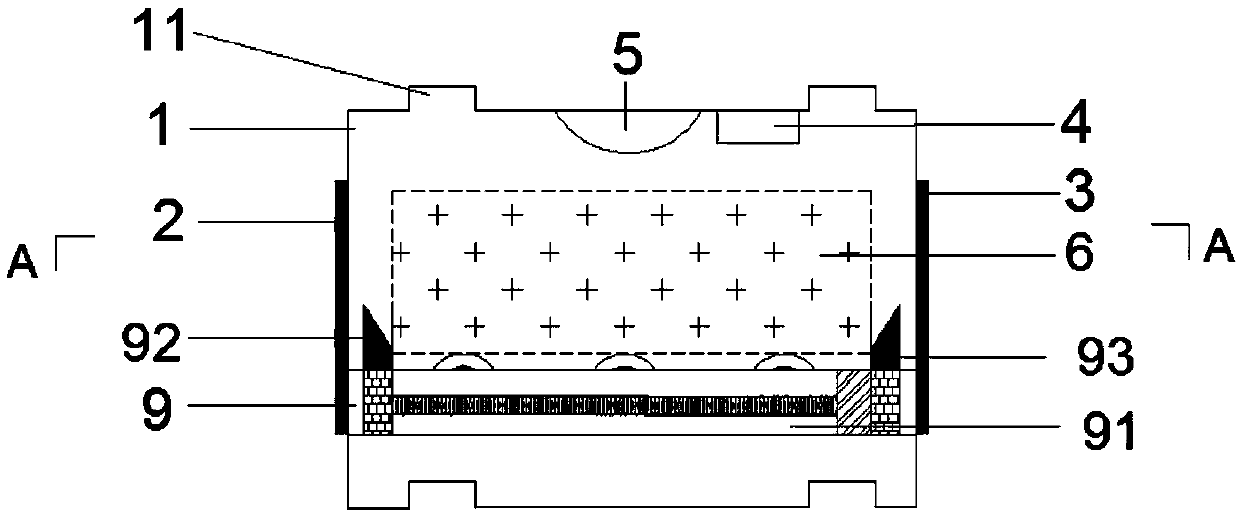

[0039] Such as Figure 1~2 , a battery module centralized storage and charging and discharging box system to ensure fire safety, including a box system and a water tank 8 arranged on one side of the box system, the box system includes a box 1, located at the front and back of the box Outbound door 2 at both ends, fire door 3, composite sensor 4 and fire sprinkler 5 at the top inside the box, a two-way motion mechanism that can push the battery 6 out of the outbound door 2 and fire door 3 inside the box, and can The control module 7 that receives the signal of the composite sensor 4 and controls the two-way motion mechanism and the fire sprinkler 5; the water tank 8 is located on the outer side of the fire door 3. Among them, the two-way motion mechanism and the control module are in Figure 1~2 not shown in

[0040] Further, the top of the box 1 used in this embodiment is provided with a convex male end 11, and the bottom is provided with a concave female end 12 matching it....

Embodiment 2

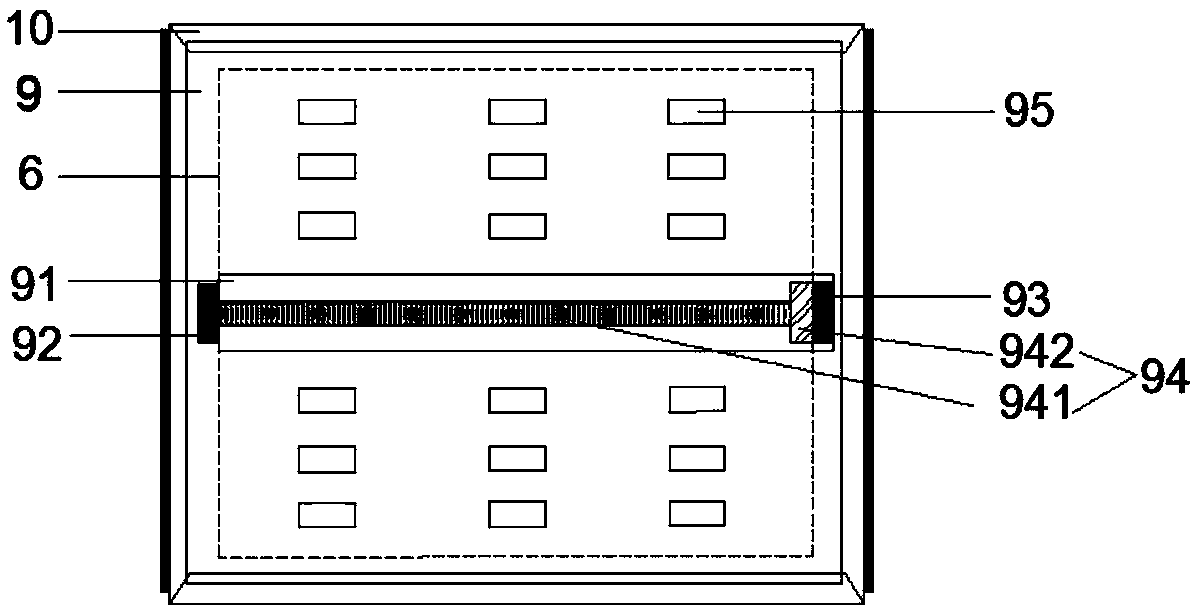

[0046] The difference from Embodiment 1 is that the two-way motion mechanism used in this embodiment includes a tray 9 for placing the battery 6 inside the box, and a chute 10 for sliding the tray 9 on the side wall of the box; the tray 9 A fire-fighting slideway 91 is provided in the thickness direction, and a fire-fighting pin 92 is provided at one end of the fire-fighting slideway 91 close to the delivery door 2, and a positioning pin 93 is provided at one end close to the fire-fighting door 3; The driving mechanism 94 on the top, the driving mechanism 94 is connected with the fire fighting pin 92 and can drive it to move along the fire fighting slide 91; the positioning pin 93 and the driving mechanism 94 are both connected with the control module 7 and controlled by it.

[0047] Of course, those skilled in the art should know that the two-way motion mechanism can also be other power mechanisms that can realize the normal discharge of batteries and emergency fire protection...

Embodiment 3

[0054] The difference from Embodiment 2 is that the driving mechanism 94 used in this embodiment is a ball screw mechanism, which includes a lead screw 941 arranged in the fire slide 91, and a limit base 942. One end of the lead screw 941 is connected to the The fire pin 92 is connected, and the other end is inserted into the limit base 942 .

[0055] The normal charge and discharge / storage and normal take-out of the battery are the same as the second embodiment, and will not be repeated here.

[0056] When the battery is out of the warehouse for emergency fire fighting, the ball screw mechanism drives the fire pin 92 to move toward the fire door 3 along the leading screw 941, and the battery is released and dropped into the water tank. The limit base 942 can ensure the stability of the fire-fighting pin moving along the lead screw, and also plays a role in limiting the extreme movement position of the fire-fighting pin 92 .

[0057] Of course, those skilled in the art should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com