Flat type copper wire twisting device used for armature windings

A technology of armature winding and flat copper wire, applied in the field of flat copper wire torsion device, can solve the problems of high cost, complex structure, unsuitable multi-layer winding, etc., and achieve the effects of low manufacturing cost, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

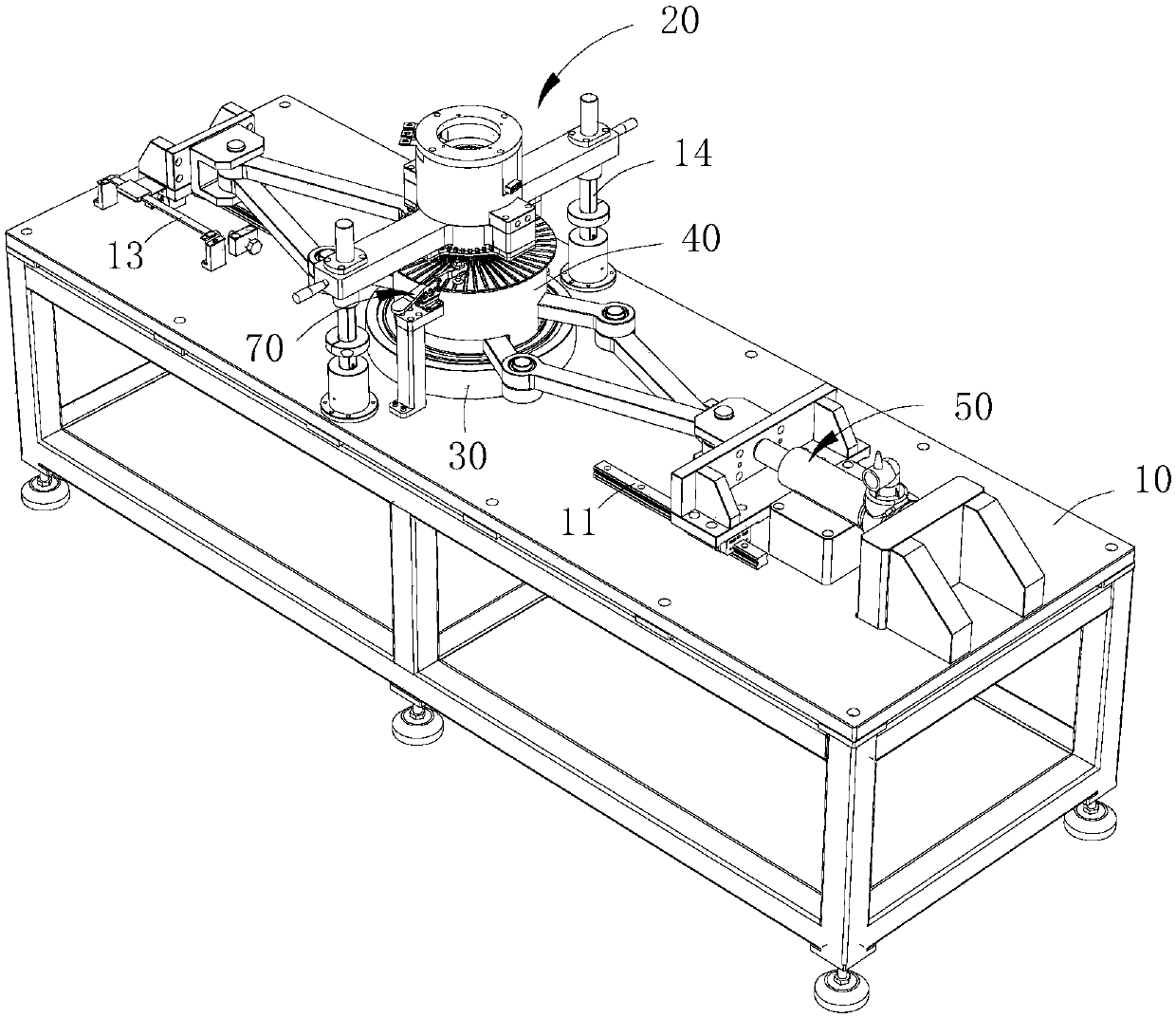

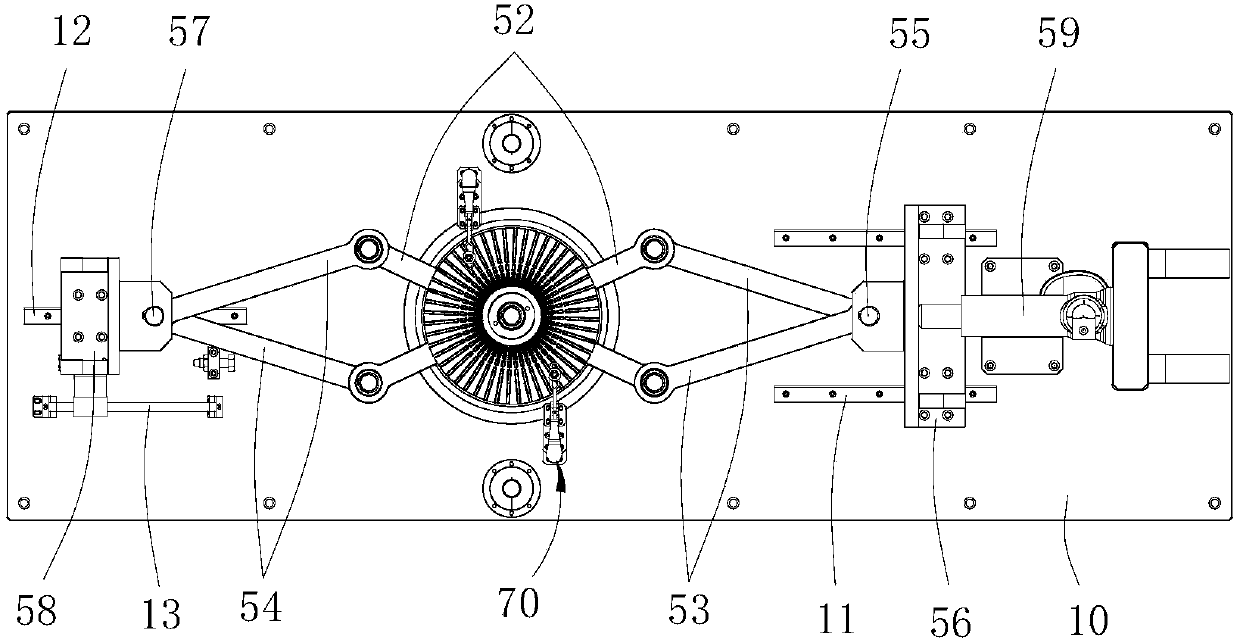

[0045] like Figures 1 to 9As shown, a flat copper wire twisting device for armature windings includes a frame 10, a clamping assembly 20 arranged above the frame 10 for clamping the armature windings, connected with the clamping assembly 20 and used for The drive card holds the armature winding clamping assembly 20 to move up and down, the conical base 30 located directly below the clamping assembly 20 and connected to the frame 10, two or more inner and outer coaxial sleeves A hollow cylindrical drum 40 and a driving mechanism 50 .

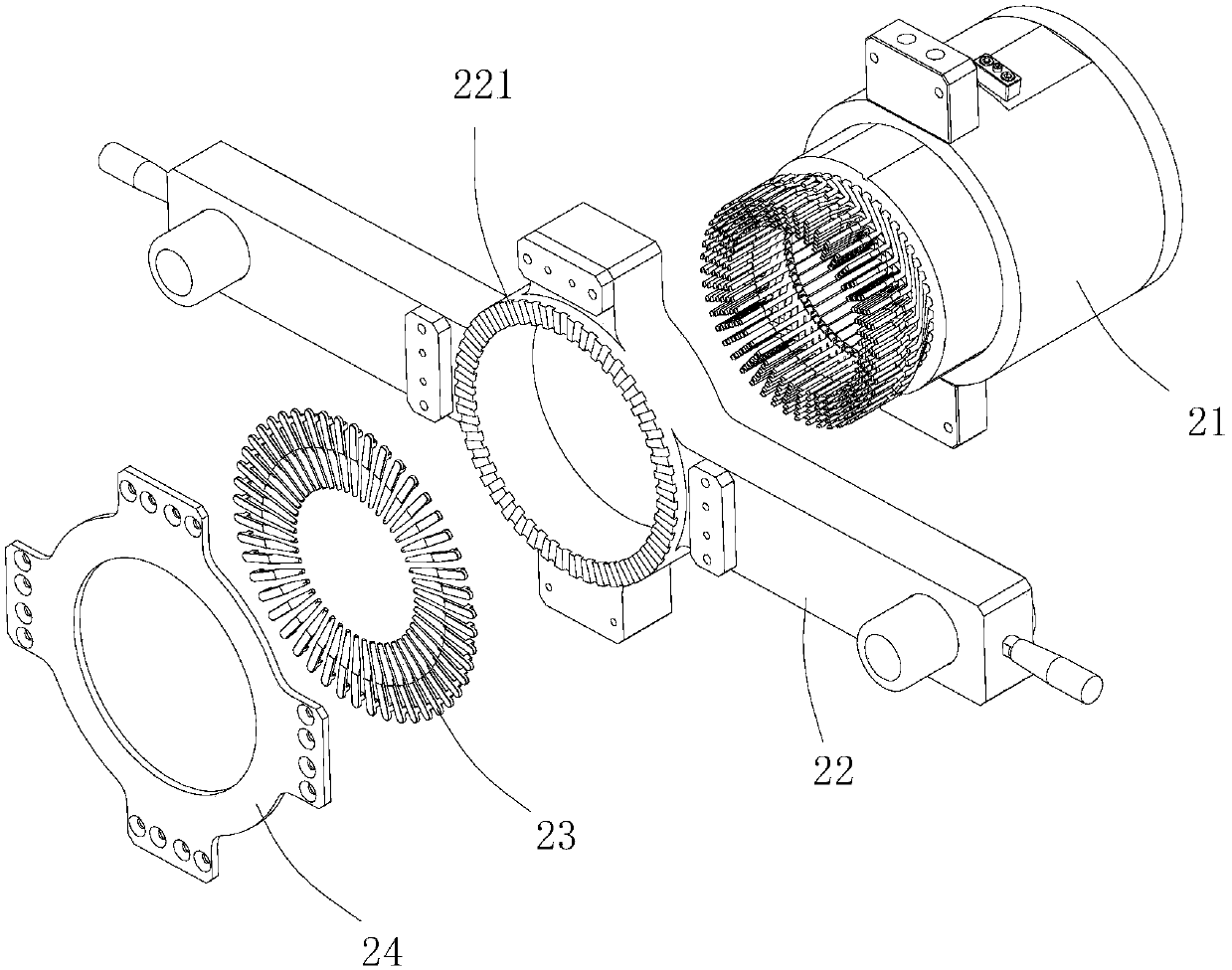

[0046] Wherein, the bottom end of each drum 40 is open, the top surface of each drum 40 is coaxially provided with a through hole 44, and the edge of each through hole 44 extends outwards with a boss 45, and the boss 45 of each drum 40 is coaxial. Outer placement; t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap