Method for preventing thin-specification strip steel from flying into coiling machine when tail losses tension

A coiler, thin gauge technology, used in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as the decline in the good rate of the coil shape, the tail cut loss, and the stacking fault of the steel coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

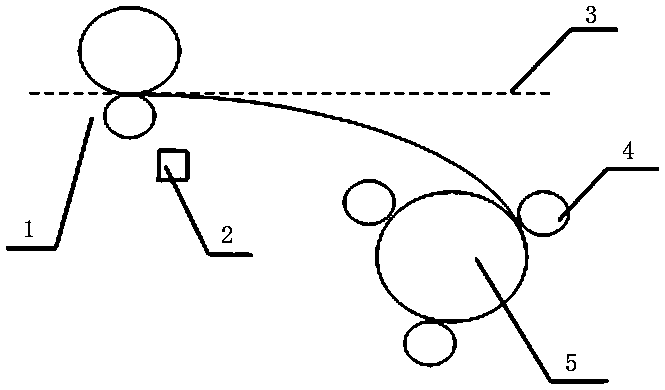

[0009] A method for solving the problem that the tail of thin-gauge strip steel loses tension and flies into the coiler. A position sensor for real-time monitoring of the real-time actual value Dt of the pinch roll gap width is installed on the coiler. The electrical signal of the position sensor is connected to the PLC. When the strip steel thickness of the take-up machine is less than or equal to 3.9mm (when coiling silicon steel with a thickness of 2.3mm), the time when the reel load relay is first connected through the PLC memory (that is, the head of the strip steel and the reel of the coiler The initial setting value of the pinch roller gap width D0 and the initial setting value of the pinch roller pressure P0, and the real-time actual value of the pinch roller gap width 2 seconds after the reel load relay is first connected through the PLC Dt, when Dt- D0≥1, modify the real-time setting value of the pinch roller pressure to 2 P0, when Dt- D0<1 or when the reel has finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com