Tin wire preparation machine

A technology for preparing machine and tin wire, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of solder wire rosin wire interruption, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

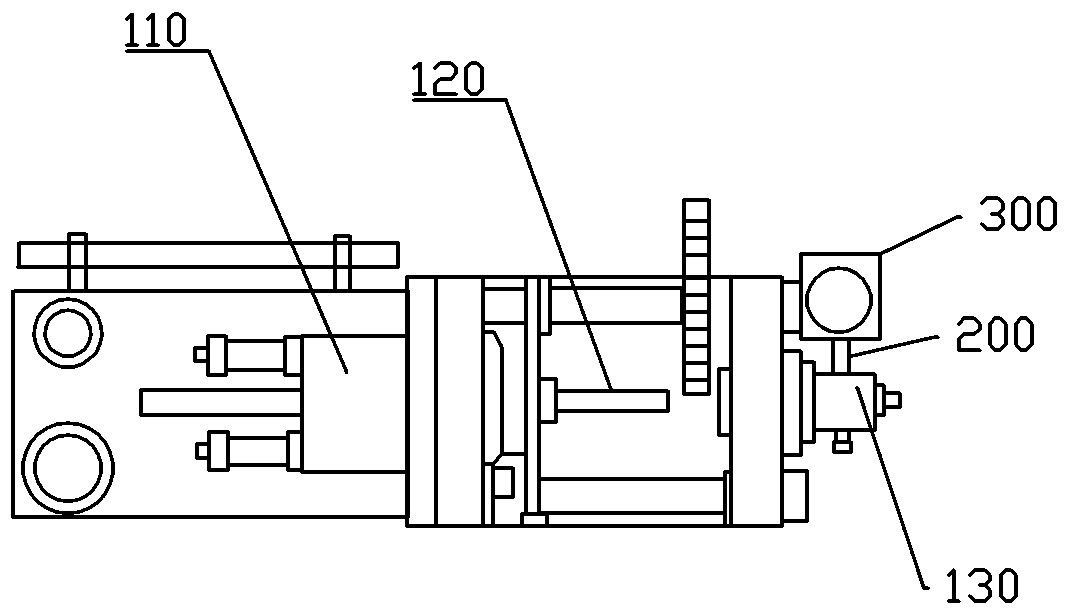

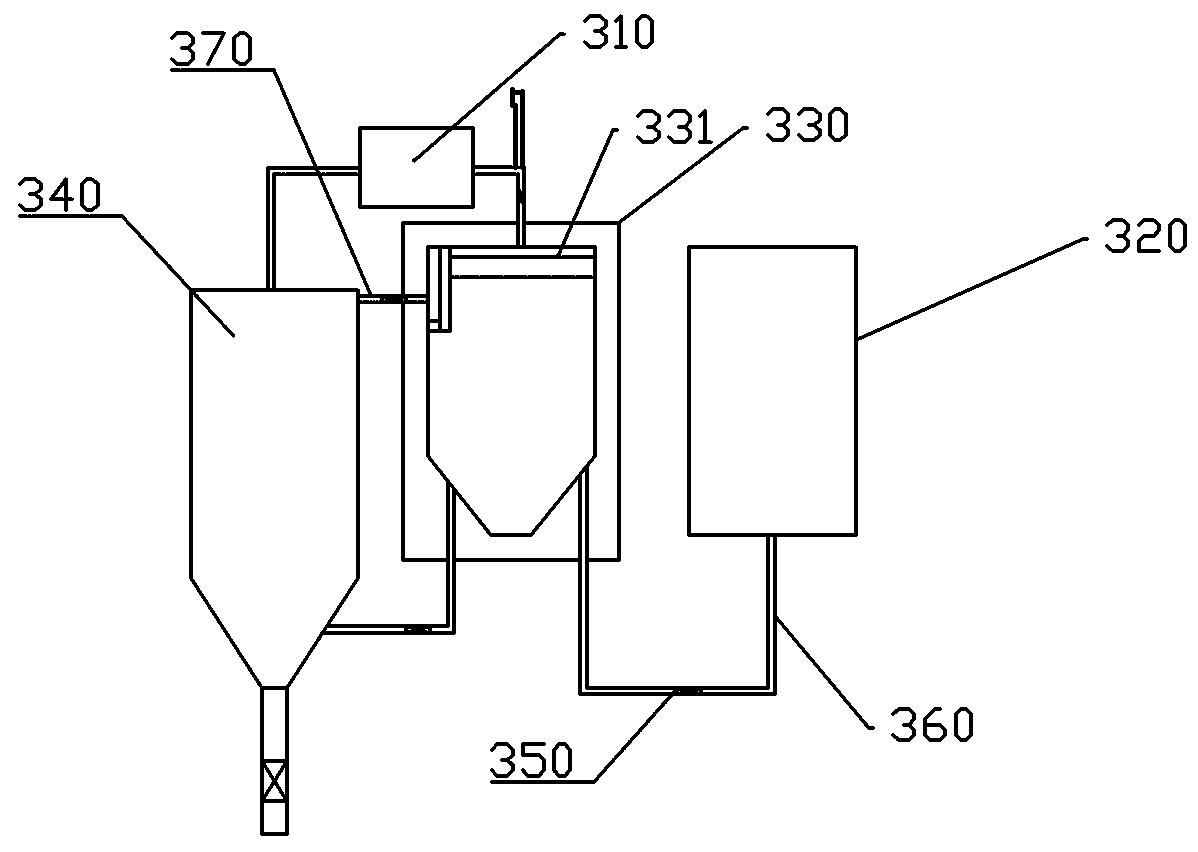

[0019] The reference signs in the drawings of the description include: hydraulic cylinder 110, extrusion rod 120, tin wire mold 130, rosin pen 200, rosin processing mechanism 300, air pump 310, melting cylinder 320, external tank 330, vibrating member 331, liquid-through Pipe 360 , vent pipe 370 , stop valve 350 , internal connection tank 340 .

[0020] Such as figure 1 The shown tin wire preparation machine includes a rosin processing mechanism, an extruding mechanism, and a rosin pen 200 connected to the rosin processing mechanism and the extruding mechanism. The rod 120 and the tin wire mold 130 that generates the tin wire, the rosin pen 200 communicates with the tin wire mold 130, the rosin processing mechanism 300 includes a melting cylinder 320 that melts the rosin at high temperature, an external tank 330 communicated with the melting cylinder 320, two liquid-th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com