Method for determining leakage in hydraulic brake system

A brake system and hydraulic technology, applied in the direction of brake safety systems, brakes, brake components, etc., can solve problems such as the inability to use caliper integrated motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

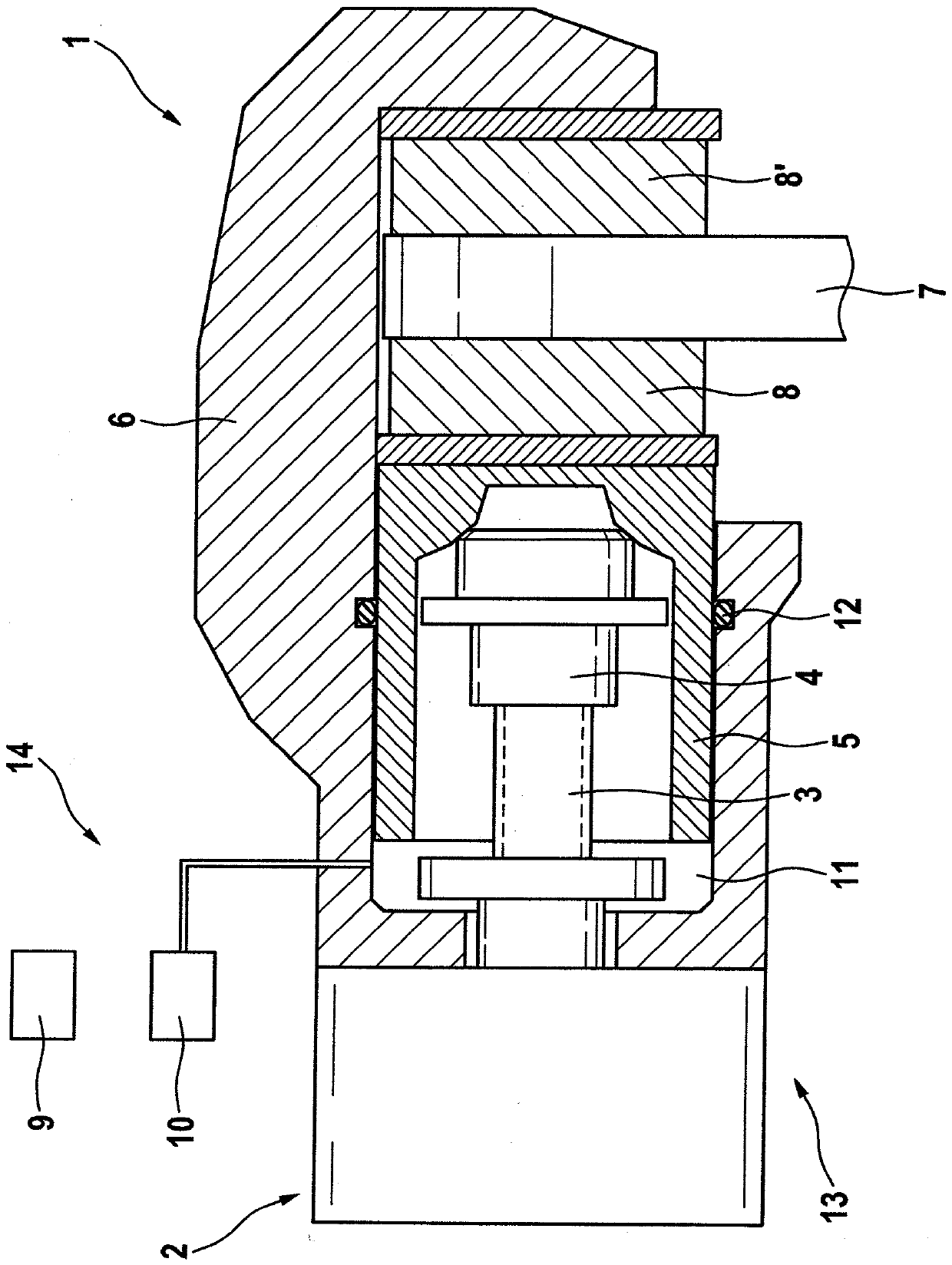

[0050] figure 1 A schematic sectional view of a braking device 1 for a vehicle is shown. The braking device 1 here has an automated parking brake 13 (also referred to as automatic parking brake or automated parking brake, APB for short), which can be activated by means of an electromechanical actuator. 2 (electric motor) to apply the clamping force used to hold the vehicle in place. For this purpose, the electromechanical actuator 2 of the parking brake 13 shown drives a spindle 3 , in particular a threaded spindle 3 , which is supported in the axial direction. On its end facing away from the actuator 2 , the spindle 3 is provided with a spindle nut 4 , which bears against the automated parking brake 13 in the pressed state. Piston 5 on. In this way, the parking brake 13 transmits force to the brake linings 8 , 8 ′ or the brake disk 7 . In this case, the spindle nut bears against the inner end face of the brake piston 5 (also referred to as the rear side of the brake pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com