Application of electrochemical method in pigment hydrolysis coating

An electrochemical method and electrochemical technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problem of high production cost of pigment hydrolysis coating, and achieve the effect of solving the uneven distribution of pH and temperature, saving cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

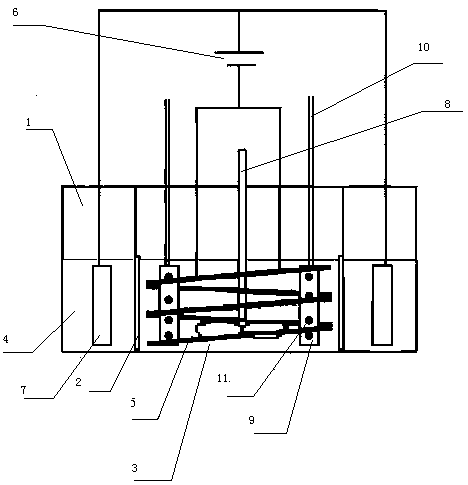

[0020] The preparation method of white matt flake nucleated pigment adopts such as figure 1 For the equipment shown, 35g of natural mica powder with a particle size of D50=4μm is put into 1L of deionized water to make a suspension, put it into the cathode chamber 3 of the electrolytic tank 1, start the agitator 8, and put in the grain regulator polyethylene Diol 0.5g, continue stirring and heating to 65°C, adjust the current size of the DC power supply 6, adjust the pH value of the suspension to 1.5, then add 4ml of SnCl with a concentration of 160g / l from the infusion tube 10 4 ·5H 2 O solution, and in the process by adjusting the current size of the DC power supply 6 to keep its pH value constant; when the SnCl 4 ·5H 2 After the addition of the O solution, continue stirring at constant temperature for 15 minutes; adjust the current of the DC power supply 6 to adjust the pH value of the suspension to 1.8-2.0, and then add 390ml of TiCl with a concentration of 2mol / l from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap