High-strength building wallboard

A high-strength, wall panel technology, applied in the direction of construction, building components, building materials, etc., can solve the problems of not being able to be used as structural materials, low strength, and use, etc., to achieve indoor temperature adjustment, mechanical performance improvement, and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

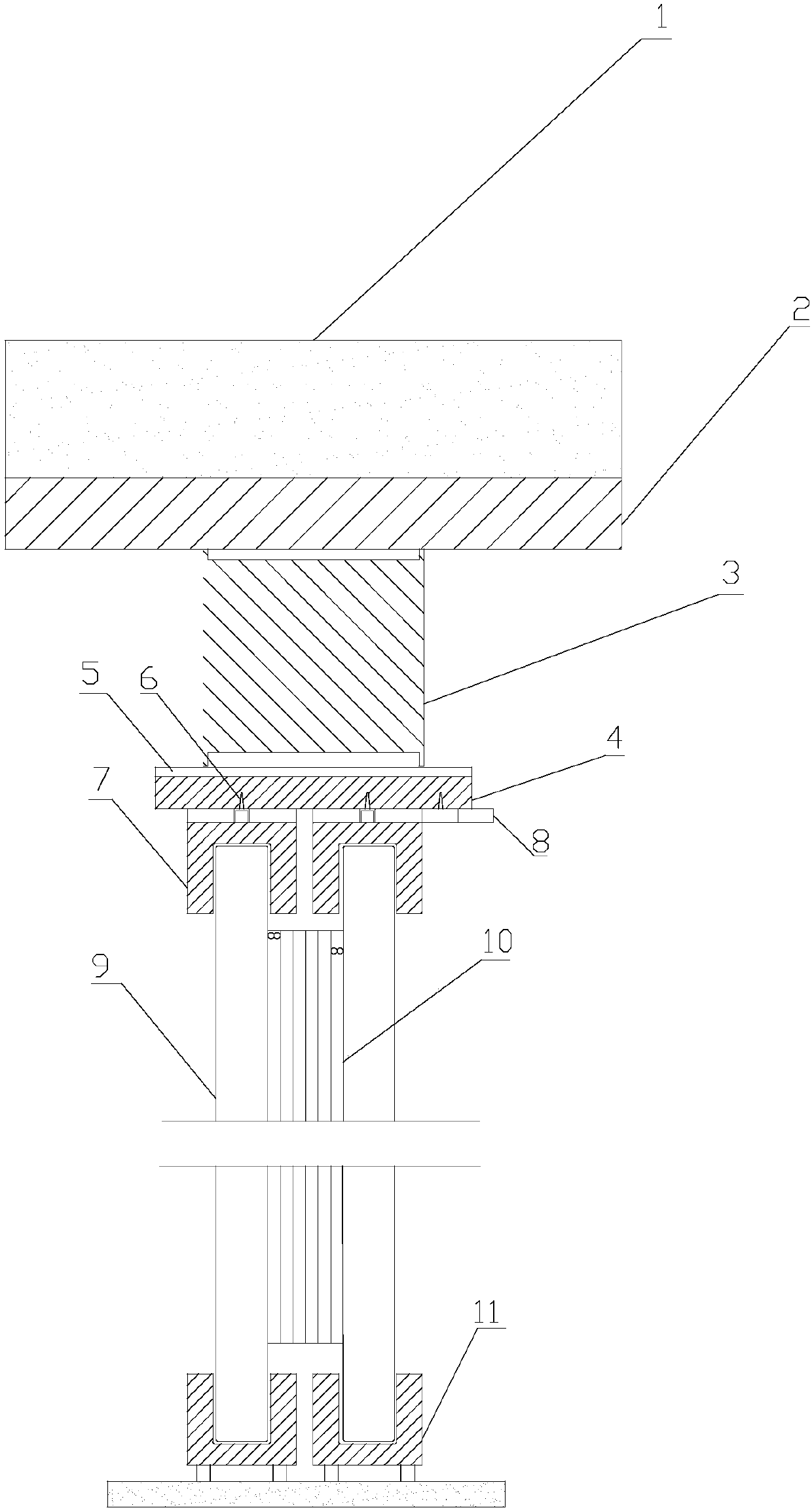

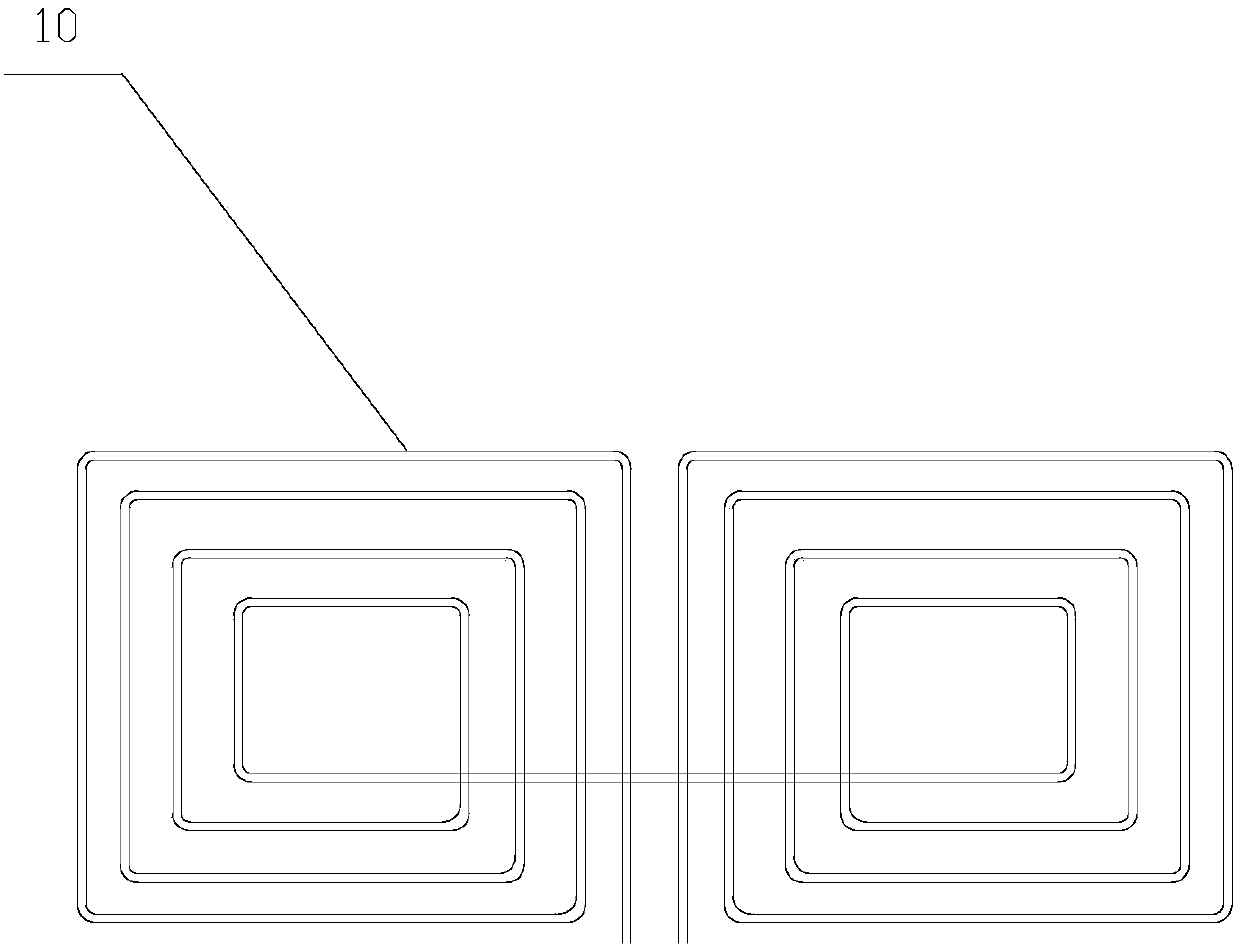

[0024] A high-strength building wall panel, consisting of roof 1, PVC board Ⅰ 2, upper fixing frame 3, beam plank 4, PVC board Ⅱ 5, self-tapping screws 6, upper wall panel frame 7, protective cover 8, building wall panel 9, heat conduction The pipe fitting 10 and the lower wall panel frame 11 are composed; the bottom of the roof 1 is bonded with a PVC plate I2, and the upper fixing frame 3 is installed under it, and the lower part is vertically bonded with a PVC plate II5, and the PVC plate II5 is bonded with the upper fixing frame 3 The corresponding other side is bonded with a crossbeam plank 4; the upper wallboard frame 7 is fixed with a self-tapping screw 6, and the upper wallboard frame 7 is fixedly connected with the crossbeam plank 4 through the self-tapping nail 6; A building wall panel 9 is clamped between the wall panel frame 7 and the lower wall panel frame 11, which makes the building wall panel 9 and the wall panel frame movably connected, facilitates the disassemb...

Embodiment 2

[0035] A kind of high-strength building wallboard, its concrete structure is as shown in embodiment 1, and its described building wallboard 9 is made up of upper layer, middle layer and lower layer, and wherein layer is the reinforced layer that metal plate is made, and the thickness of its reinforced layer It is 30% of the high-strength building wallboard. The upper and lower layers are covering layers made of wood-plastic materials, and the covering layer and the reinforcing layer are bonded by adhesives. The building wallboard with its structure increases the mechanical properties of the wallboard. Effectively prevent earthquake disasters.

[0036] The wood-plastic material of the covering layer is low-melting nylon wood-plastic, which contains the following components, and the parts by weight of each component are respectively:

[0037] Low melting point nylon: 60 parts;

[0038] Wood fiber: 35 parts;

[0039] Chain extender: 5 parts;

[0040] Lubricant: 6 parts;

[00...

Embodiment 3

[0044] The building wallboard 9 is composed of an upper layer, a middle layer and a lower layer, wherein the layer is a reinforcement layer made of a metal plate, and the thickness of the reinforcement layer is 40% of that of the high-strength building wallboard, and the upper layer and the lower layer are made of wood-plastic materials. The covering layer is formed, and the covering layer and the reinforcing layer are bonded by adhesive, and the building wallboard of its structure increases the mechanical properties of the wallboard, which can effectively prevent earthquake disasters.

[0045] The wood-plastic material of the covering layer is low-melting nylon wood-plastic, which contains the following components, and the parts by weight of each component are respectively:

[0046] Low melting point nylon: 35 parts;

[0047] Wood fiber: 55 parts;

[0048] Chain extender: 8 parts;

[0049] Lubricant: 5 parts;

[0050] Pigment: 5 parts;

[0051] It can give full play to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com