A Fracturing Method for Low Permeability Heavy Oil Reservoir

A heavy oil reservoir, low permeability technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of low formation heating capacity, casing damage, difficult development, etc., and achieve improved stimulation effect , reduce cold damage, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example provides a technical method for improving the fracturing effect of low-permeability heavy oil reservoirs. In this method, a well in Huabei Oilfield is selected as a test oil well. Rate 5-10 x 10 -3 μm2 , porosity 12-17%, formation pressure 17MPa, reservoir thickness 15m. The technical method of the present embodiment comprises the following steps:

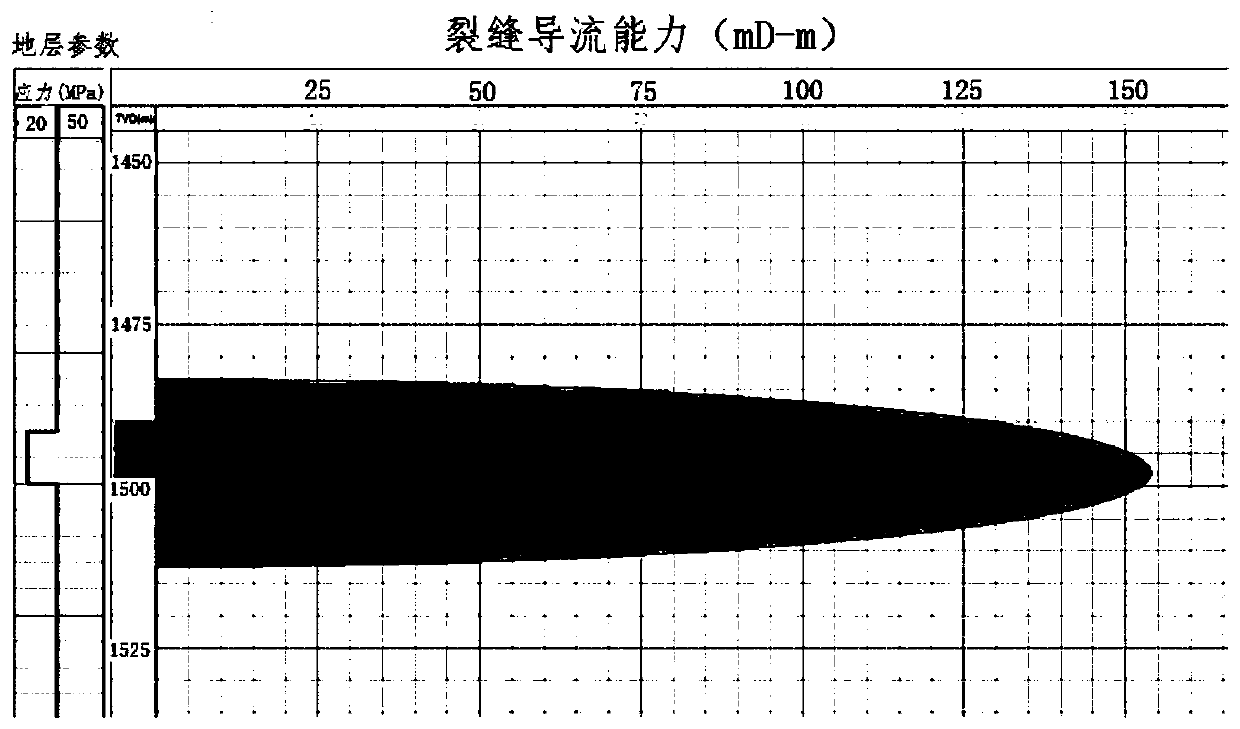

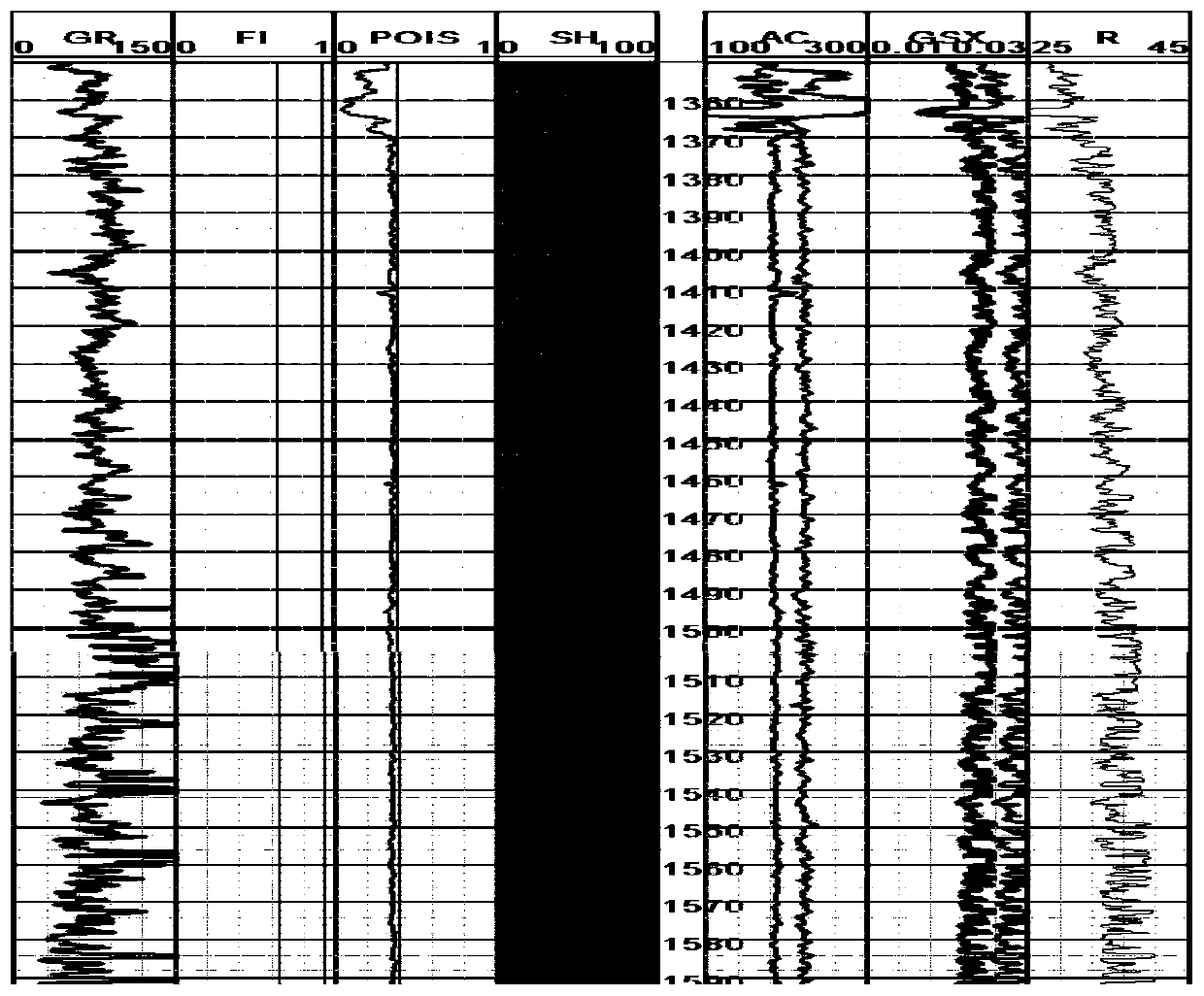

[0037] Step 1: According to the indoor triaxial mechanical experiment and logging data, the rock mechanical parameters of the reservoir are calculated as Young's modulus of 11200-19870MPa, Poisson's ratio of 0.17-0.22 (the indoor triaxial mechanical experiment and measured The method of calculating rock mechanical parameters from well data is a conventional method in this field), according to the designed pump injection program, the effective length of the propped fracture is 140m by using the FracPT fracturing design software simulation, as figure 1 shown.

[0038] According to the fracture simulation result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com