Elastic sealing ring and circular-arc slide sealing device

An elastic sealing and sliding sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem that the sealing device and method cannot meet the requirements, and achieve large pressure opening, good stability and support, and good sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

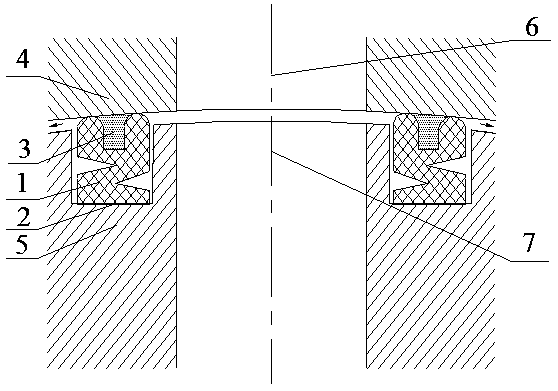

[0036] Embodiment 1: as Figure 1-2 As shown, an elastic sealing ring and an arc sliding sealing device include an elastic sealing ring 1, a sealing groove 2, a grease 3, an arc surface fixing part 4, an arc surface rotating part 5, a liquid flow hole I6, a liquid flow Hole Ⅱ7; the elastic sealing ring 1 is installed in the sealing groove 2, and the sealing groove 2 is opened on the sliding surface of the arc surface rotating part 5, and the grease 3 is applied between the elastic sealing ring 1 and the arc surface fixing part 4, and the arc surface The surface rotating part 5 is installed in the circular arc surface fixing part 4 through clearance fit, and the sealing port is circular. The liquid flows into the liquid flow hole II7 through the liquid flow hole I6 or flows into the liquid flow hole I6 through the liquid flow hole II7, and the liquid flow hole II7 can also form a through-flow sealing blind hole.

[0037] The elastic sealing ring 1 is a Z-shaped elastic sealing...

Embodiment 2

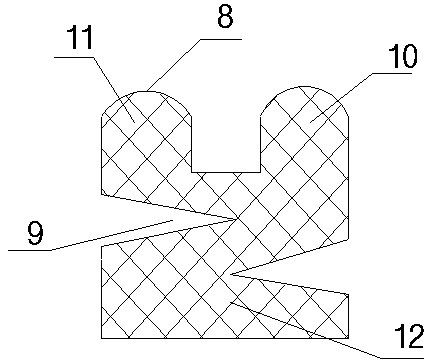

[0043] Embodiment 2: as Figure 3-4As shown, an elastic sealing ring and an arc sliding sealing device include an elastic sealing ring 1, a sealing groove 2, a grease 3, an arc surface fixing part 4, an arc surface rotating part 5, a liquid flow hole I6, a liquid flow Hole Ⅱ7; the elastic sealing ring 1 is installed in the sealing groove 2, and the sealing groove 2 is opened on the sliding surface of the arc surface rotating part 5, and the grease 3 is applied between the elastic sealing ring 1 and the arc surface fixing part 4, and the arc surface The surface rotating part 5 is installed in the circular arc surface fixing part 4 through clearance fit, and the sealing port is circular. The liquid flows into the liquid flow hole II7 through the liquid flow hole I6 or flows into the liquid flow hole I6 through the liquid flow hole II7, and the liquid flow hole II7 can also form a through-flow sealing blind hole.

[0044] The elastic sealing ring 1 is an oblique U-shaped elastic...

Embodiment 3

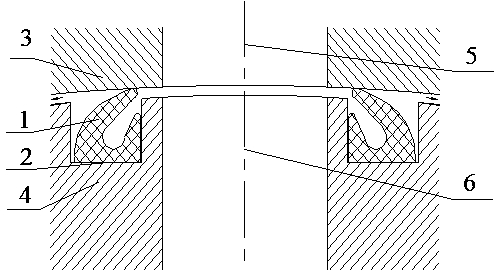

[0049] Embodiment 3: as Figure 5-6 As shown, an elastic sealing ring and an arc sliding sealing device include an elastic sealing ring 1, a sealing groove 2, a grease 3, an arc surface fixing part 4, an arc surface rotating part 5, a liquid flow hole I6, a liquid flow Hole Ⅱ7; the elastic sealing ring 1 is installed in the sealing groove 2, and the sealing groove 2 is opened on the sliding surface of the arc surface rotating part 5, and the grease 3 is applied between the elastic sealing ring 1 and the arc surface fixing part 4, and the arc surface The surface rotating part 5 is installed in the circular arc surface fixing part 4 through clearance fit, and the sealing port is circular. The liquid flows into the liquid flow hole II7 through the liquid flow hole I6 or flows into the liquid flow hole I6 through the liquid flow hole II7, and the liquid flow hole II7 can also form a through-flow sealing blind hole.

[0050] The elastic sealing ring 1 is a multi-lip elastic sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com