Conduction oil boiler feeding device

A technology of heat transfer oil boiler and feeding device, which is applied in supply configuration, fuel supply, solid fuel pretreatment, etc., can solve problems such as low efficiency, manual stirring, and waste of manpower and material resources, and achieve the effect of high efficiency and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

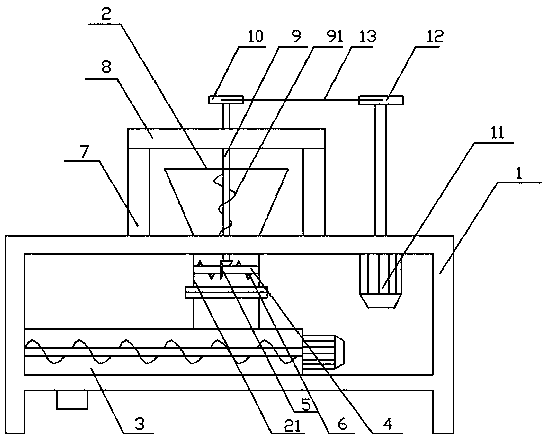

[0012] Such as figure 1 As shown, the present invention discloses a heat conduction oil boiler feeding device, comprising: a bracket 1, a feeding hopper 2, a screw conveyor 3, a rotating shaft 4, a bevel gear 5, a crushing cone 6, a column 7, a horizontal plate 8, a vertical Shaft 9, belt pulley one 10, motor 11, belt pulley two 12, belt 13, described feed hopper 2 is installed on support 1 top, and described screw conveyer 3 is installed on support 1 lower side, described feed hopper 2 The lower part is provided with a straight barrel portion 21, the straight barrel portion 21 of the feed hopper 2 is fixedly connected with the inlet of the screw conveyor 3, the rotating shaft 4 is installed in the straight barrel portion 21 through bearing rotation, and the bevel gear 5 is installed on the On the rotating shaft 4, the outer peripheral surface of the rotating shaft 4 is affixed with broken cones 6 distributed randomly, and a column 7 is vertically installed on the brackets 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com