Vortex heater

A heater and vortex technology, which is applied in the field of vortex heaters, achieves the effects of low manufacturing cost, increasing heat exchange area and preventing ice blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

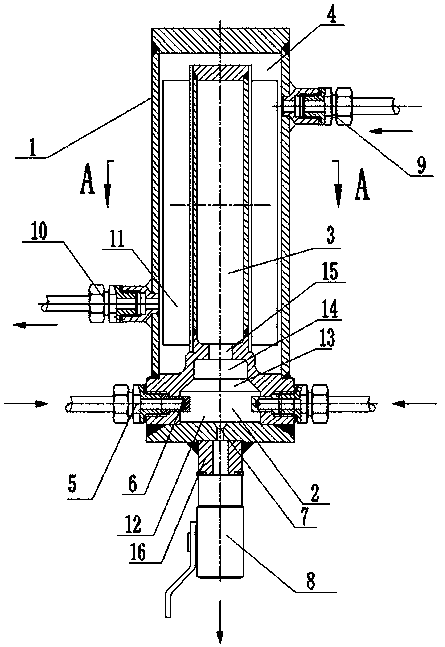

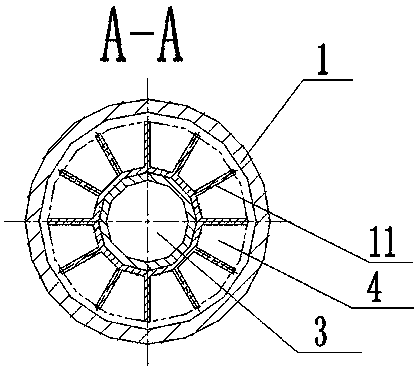

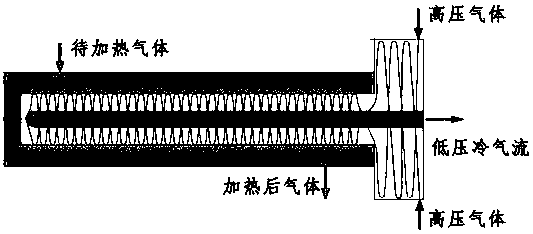

[0029] As a preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0030] The vortex heater includes a heater body 1. The heater body 1 is provided with an air inlet chamber 2, a heating chamber 3 and a heat exchange chamber 4. The air inlet chamber 2 communicates with the heating chamber 3, and the air inlet chamber 2 An air inlet 5 is arranged on the air inlet 5, and a nozzle 6 is arranged at the air inlet 5, and the nozzle 6 injects the gas entered by the air inlet 5 into the air inlet chamber 2 along the tangential direction of the inner wall of the air inlet chamber 2, and the air inlet chamber 2. The diameter of one end of the upper air inlet 5 is greater than the diameter of the end of the air inlet chamber 2 communicating with the heating chamber 3. The air inlet chamber 2 is also provided with an exhaust port 7 for exhausting. The exhaust port 7 is externally connected to the There is an exhaust ball valv...

Embodiment 2

[0033] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0034] The vortex heater includes a heater body 1. The heater body 1 is provided with an air inlet chamber 2, a heating chamber 3 and a heat exchange chamber 4. The air inlet chamber 2 communicates with the heating chamber 3, and the air inlet chamber 2 An air inlet 5 is arranged on the air inlet 5, and a nozzle 6 is arranged at the air inlet 5, and the nozzle 6 injects the gas entered by the air inlet 5 into the air inlet chamber 2 along the tangential direction of the inner wall of the air inlet chamber 2, and the air inlet chamber 2. The diameter of one end of the upper air inlet 5 is greater than the diameter of the end of the air inlet chamber 2 communicating with the heating chamber 3. The air inlet chamber 2 is also provided with an exhaust port 7 for exhausting. The exhaust port 7 is externally connected to the There is an exhaust bal...

Embodiment 3

[0038] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0039] The vortex heater includes a heater body 1. The heater body 1 is provided with an air inlet chamber 2, a heating chamber 3 and a heat exchange chamber 4. The air inlet chamber 2 communicates with the heating chamber 3, and the air inlet chamber 2 An air inlet 5 is arranged on the air inlet 5, and a nozzle 6 is arranged at the air inlet 5, and the nozzle 6 injects the gas entered by the air inlet 5 into the air inlet chamber 2 along the tangential direction of the inner wall of the air inlet chamber 2, and the air inlet chamber 2. The diameter of one end of the upper air inlet 5 is greater than the diameter of the end of the air inlet chamber 2 communicating with the heating chamber 3. The air inlet chamber 2 is also provided with an exhaust port 7 for exhausting. The exhaust port 7 is externally connected to the There is an exhaust bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com