Insulating oil sampling equipment facilitating quantitative oil taking

A technology for sampling equipment and insulating oil, applied in the direction of sampling devices, etc., can solve problems such as unsatisfactory inspection results, deterioration of insulating oil, and pollution of insulating oil, and achieve the effects of avoiding repeated sampling inspections, low cost, and convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

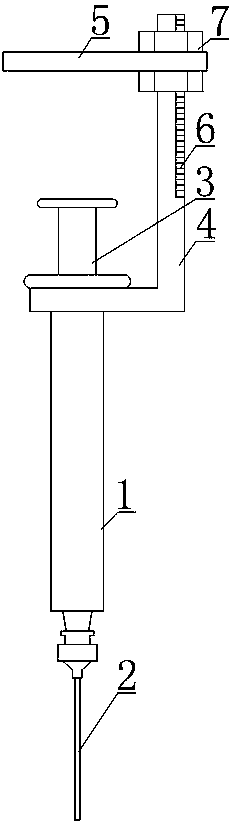

[0014] Such as figure 1 As shown, the insulating oil sampling equipment for quantitative oil sampling includes a sampling tube 1, a needle 2, a sampling push-pull rod 3, a positioning connecting rod 4, a limit rod 5 and a positioning nut 7, wherein the sampling tube 1 is vertically arranged, and the needle 2 is connected to the lower end of the sampling tube 1 and connected to the inside of the sampling tube 1 , and the sampling push-pull rod 3 is inserted into the sampling tube 1 from the upper end of the sampling tube 1 . The positioning connecting rod 4 of the present embodiment comprises a horizontal connecting rod arranged horizontally and a vertical positioning rod arranged vertically. For the structural strength of the example, in this embodiment, the horizontal connecting rod and the vertical positioning rod in the positioning connecting rod 4 are integrated into one, and the positioning connecting rod 4 is an "L"-shaped structure as a whole.

[0015] The outer wall o...

Embodiment 2

[0017] This embodiment makes the following further limitations on the basis of Embodiment 1: the outer wall of the vertical positioning rod of this embodiment is provided with a scale 6, so that when this embodiment is applied, it is convenient to control by the scale 6

[0018] Sampling volume in sampling tube 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com