Sample presser workstation for gravelled graphitized soil and manufacturing method of sample presser workstation

A technology of pressing machine and fossil, which is applied in the field of agricultural tools, can solve the problems of easy damage, far different requirements, fragmentation and wear of metal pressing machine, so as to achieve stable mechanical properties, improve fatigue resistance, and improve impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

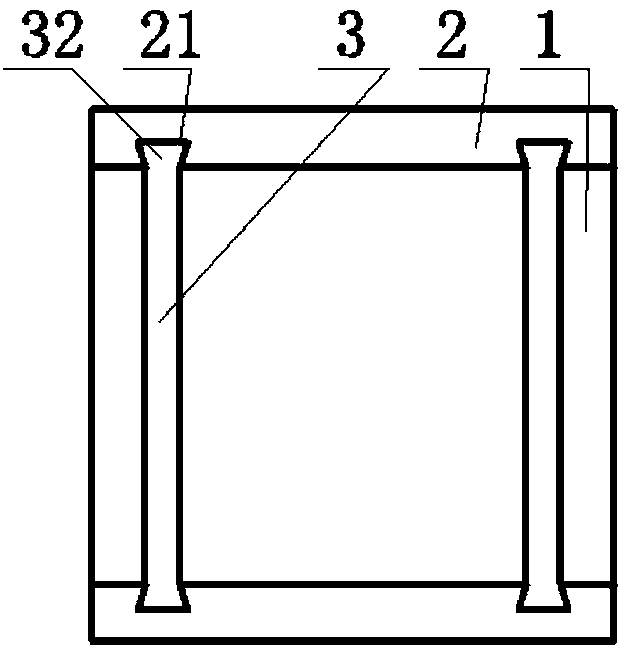

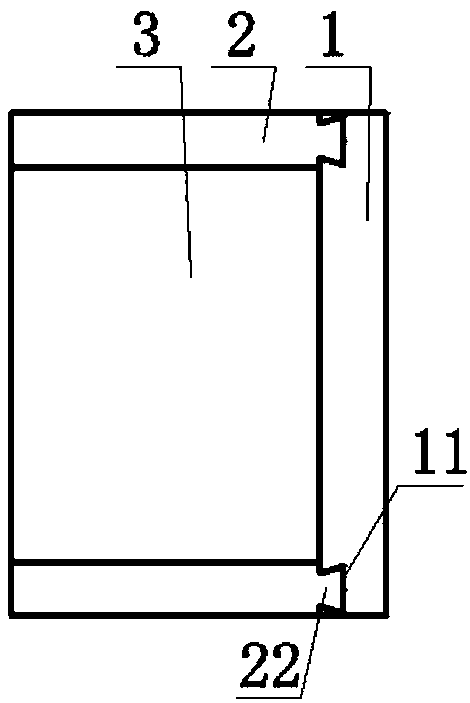

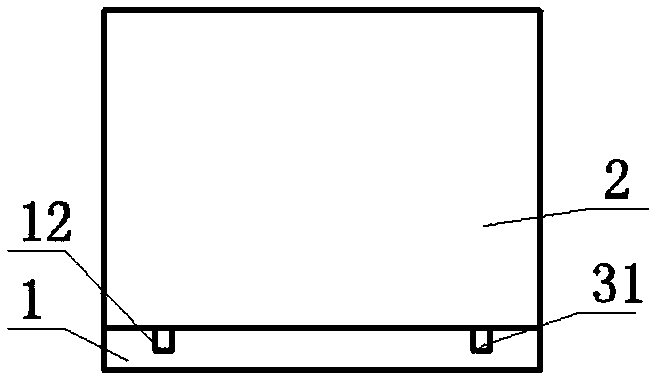

[0022] A sample press station for gritty and graphitized soil, comprising a bottom plate 1, two first side plates 2, two second side plates 3, and a bottom plate 1, two first side plates 2, two A cuboid top block suitable for the space enclosed by the second side plate 3, wherein: the bottom plate 1 is provided with two first trapezoidal dovetail grooves 11 parallel to each other and the other two parallel to each other and the center of the first dovetail groove A rectangular groove 12 with a vertical line, the first trapezoidal dovetail groove 11 is specifically a linear groove with an opening narrower than the bottom, left and right symmetrical, and a hypotenuse angle of 20°; Compatibility and the first trapezoidal wedge 22 with a unilateral fit gap of 0.18mm-0.21mm, and two second trapezoidal dovetail grooves 21 parallel to each other and with a hypotenuse angle of 15° are respectively arranged on the side of the first side plate 2; The bottom of the second side plate 3 is...

Embodiment 2

[0034] The whole is consistent with Example 1, the difference is:

[0035] All slots and wedges are bonded with 793 glass glue.

[0036] A method for manufacturing the above-mentioned glass-encapsulated ceramic sand material, comprising the following steps:

[0037] ③ Mix ceramic sand and fluid glass according to the mass ratio of 1.3:1 and stir evenly to obtain turbid glass fluid;

[0038] ⑦Keep the temperature of the first altering liquid and the second altering liquid constant, and immerse the rough billet in the first altering liquid and the second altering liquid in turn. Immerse in the metamorphic solution for 30 minutes to obtain the toughened rough billet;

Embodiment 3

[0040] All grooves and wedges are bonded with YT932 glue.

[0041] A method for manufacturing the above-mentioned glass-encapsulated ceramic sand material, comprising the following steps:

[0042] ③ Mix ceramic sand and fluid glass according to the mass ratio of 1.4:1 and stir evenly to obtain turbid glass fluid;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com