Method for designing corrosion allowance of metal grounding material in electric power system

A metal grounding and design method technology, applied in the field of power systems, can solve the problems of waste, unsuitable power grounding, grounding grid failure, etc., and achieve the effect of reducing the use cost and the design method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

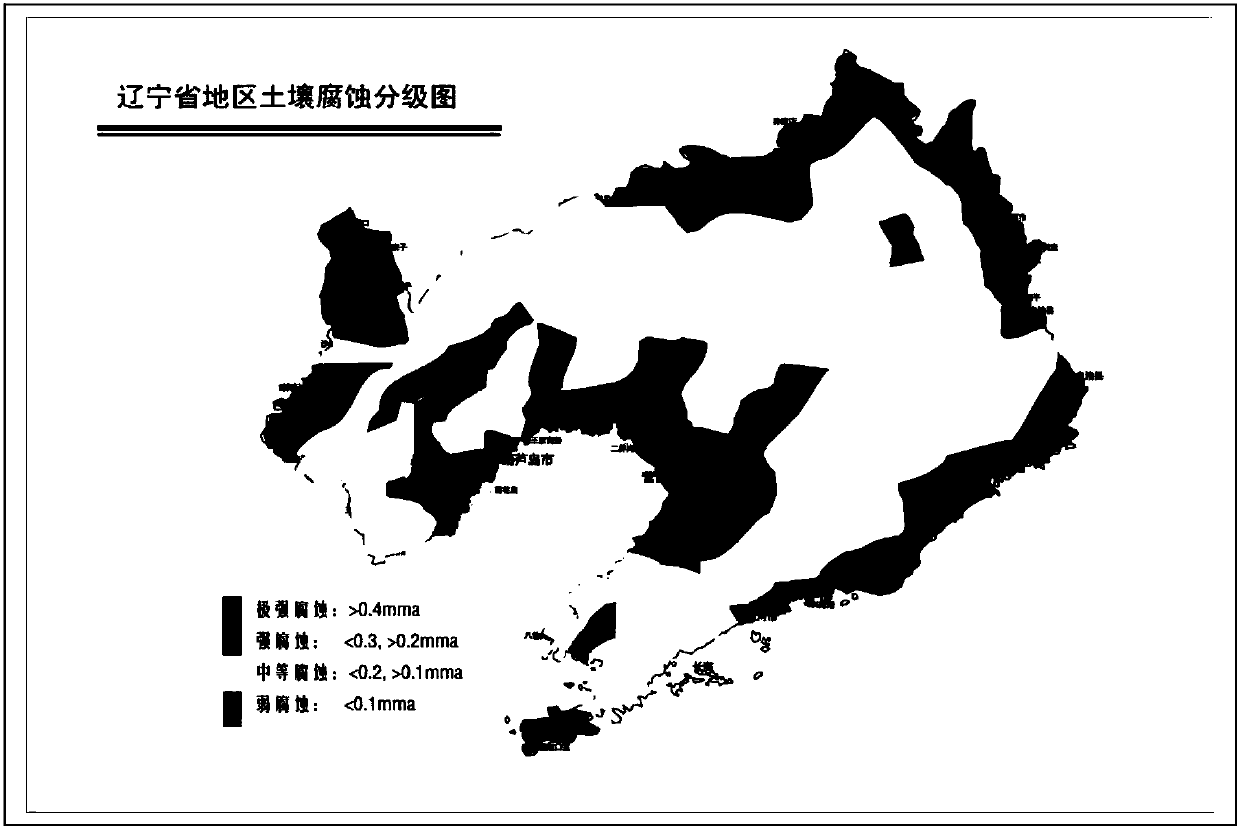

[0067] The method of the invention is used to carry out grading research on the corrosion rate of steel materials in the Liaoning area, and the soil index data required for the grading comes from the field test results of the soil in the Liaoning area. Such as figure 1 As shown, from the soil corrosion classification diagram of steel grounding materials in Liaoning area, it can be seen that the corrosion classification in Shenyang area is medium corrosion, and the electrochemical corrosion rate takes the maximum value Ve=0.2mm / a. The relationship between the power frequency ground current and the current density of carbon steel materials is:

[0068] Vc=ln(0.98+0.0065I)

[0069] If the power frequency maximum grounding current I of the substation grounding grid is 20mA / m 2 , a=0.98, b=0.0065, using the above formula to calculate the corrosion rate of power frequency into the ground current is 0.105mm / a.

[0070] Taking the service life of the grounding material as 20 years,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com