Automatic recognition method for fatigue fracture of elastic strip of high-speed railway steel rail fastener

A technology for high-speed railways and fatigue fractures, applied in character and pattern recognition, roads, rails, etc., can solve the problems of lack of fast detection of fastener clips, etc., to overcome the waste of manpower and material resources, and improve the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

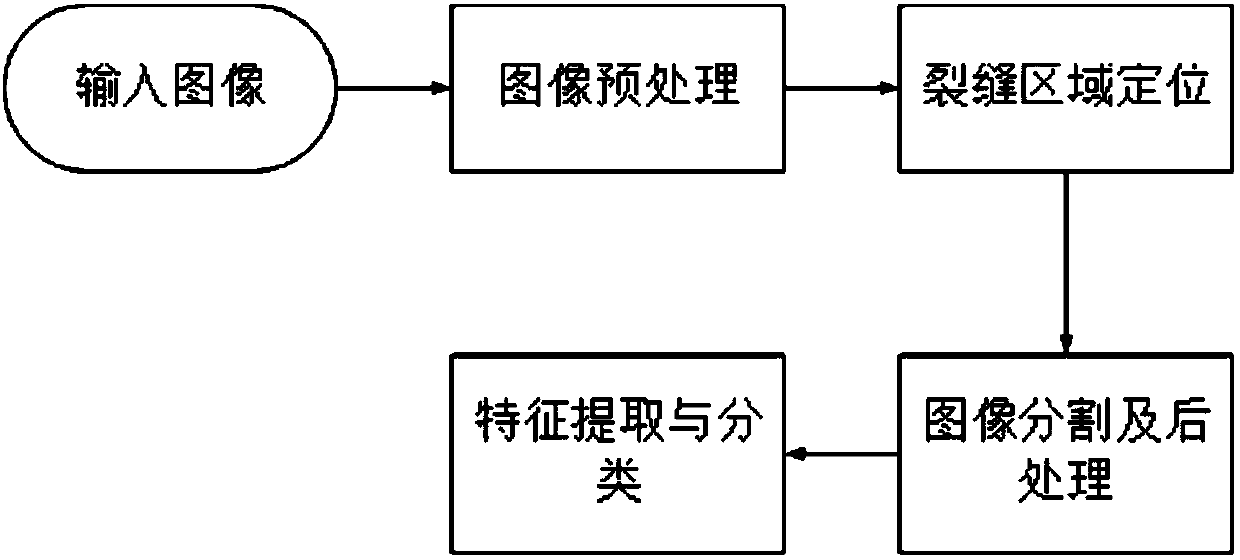

[0052] When the present invention is used for crack identification of clips, the specific steps are as follows:

[0053] S1: Image preprocessing process:

[0054] S1-1: Input the image to be recognized. Among them, the image to be recognized is taken by an automatic control industrial camera, and the real image obtained in real time, such as figure 1 .

[0055] S1-2: Image denoising: take the median filter of 3×3 template on the input image, and remove the scattered noise in the image while retaining the crack details.

[0056] S1-3: Image grayscale: The image collected by the camera is a 24-bit true color image, which needs to be converted into a grayscale image for subsequent processing.

[0057] S1-4: Image enhancement: Gamma corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com